EN

30

Disconnect the electric motor from the power supply and mark the phase connections for later connection..

6.3 Delivery pipe

If the delivery pipe is connected to the pump using a tool such as a pipe wrench, the pump may only be mounted to

the delivery chamber. The threaded joints of the delivery pipe must be well cut and fitted together to ensure that they

do not loosen due to the rotational reaction caused by starting and stopping the pump. The thread of the first section

of delivery pipe to be screwed into the pump must not be longer than the thread in the pump. If there is a possibility of

noise transmission into the building through the pipework, plastic piping is recommended.

If plastic piping is used, the pump must be fixed with an unloaded tension wire attached to the delivery chamber of the

pump.

6.4 Starting the pump

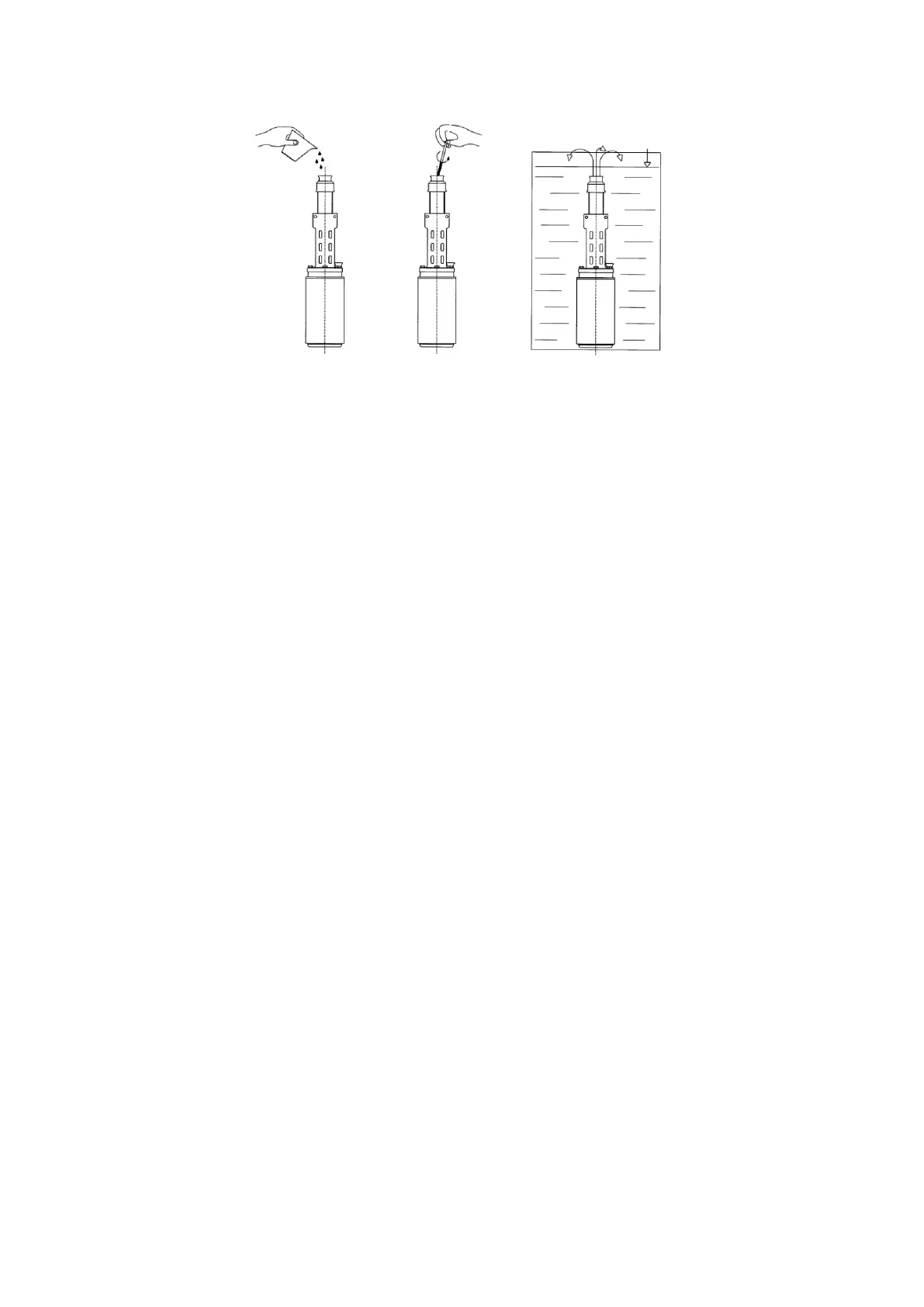

Before pump installation

1. If the pumping unit is to be installed in a borehole, recheck the entire length of the borehole by lowering a check

cylinder or a 94 mm diameter, 715 mm long pipe. This cylinder or pipe must pass unopposed through the entire

borehole. In this way, the depth of the borehole and, where appropriate, the level in the borehole are determined

at the same time. The minimum borehole diameter for the pumping unit is 100 mm.

2. According to the depth of the borehole or well and the minimum level, the length of the pipe, cable and

suspension line is prepared. The piping must be selected with sufficient strength and with strong joints - taking

into account the weight of the pump set piping and water. It is recommended to use new pipe with well tightened

threaded joints. If plastic piping is used, the pump must only be lowered and raised using a suspension cable.

Attach the suspension line to the pump using the prepared holes in the top of the suction casing.

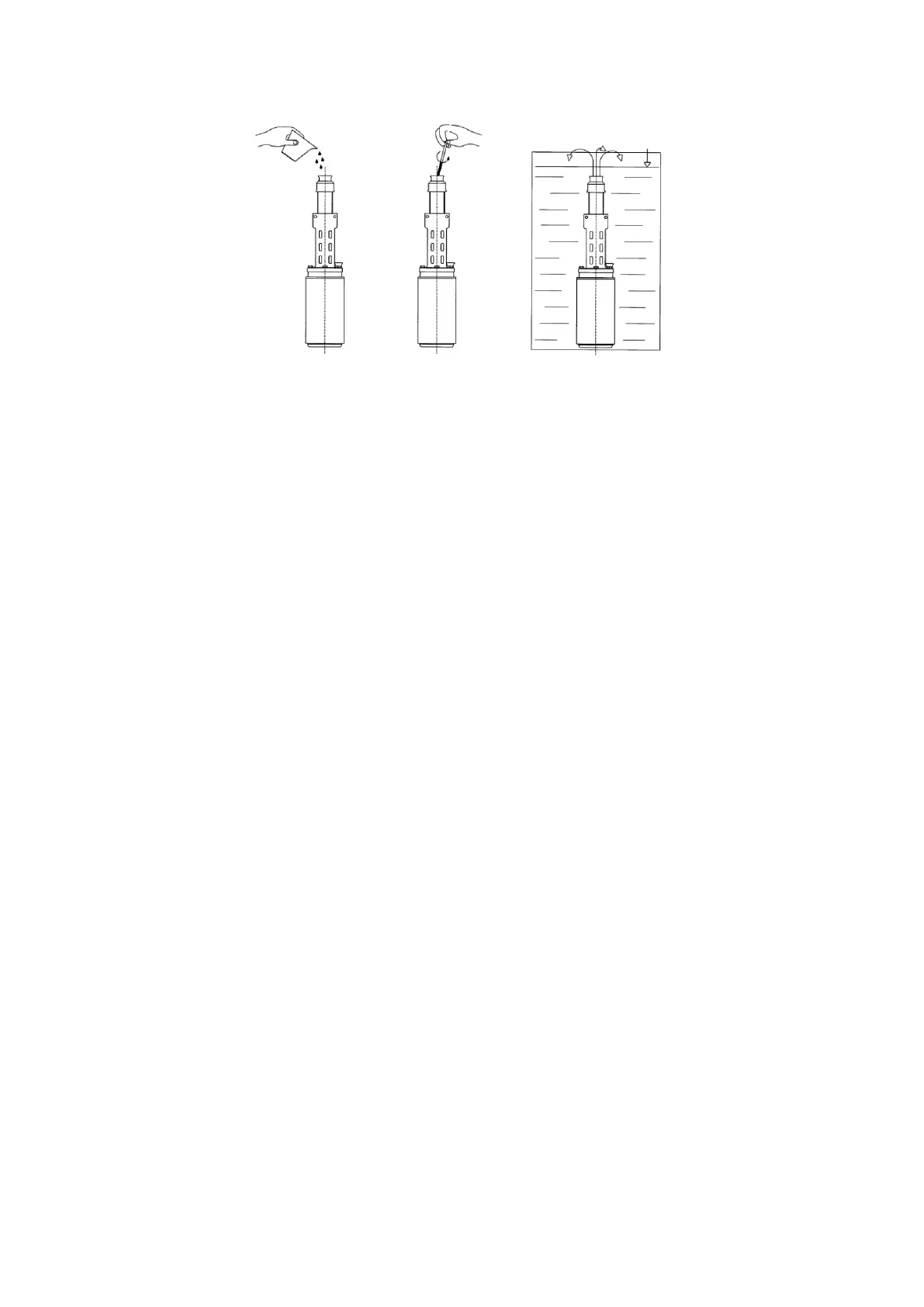

3. To suspend the unit and the pipe into the excavated well, steel beams are prepared and walled up to safely

support the load. It is recommended that the beams be positioned so that they do not obstruct access to the

well. In the case of drilled wells, the mounting clip may be supported directly on the top edge of the casing,

which must be at least as deep as the pipe leaving the well into the ground. In this case, it is better to extend the

borehole to this depth with a larger diameter, which needs to be cased with large concrete rings as in the case of

a drilled well. If plastic pipe is used, the pump must be lowered and pulled out only by suspension cable.

Between the pump and the safety valve there must be a smooth pipe with a constant cross-section without a shut-off

valve!

For starting the pump using a suitable starting device. Do not handle the pump by pulling on the power cable - it is not

designed for this purpose and there is a risk of the pump being torn off. Before starting the pump, the delivery throat

must be primed with water.

In case of use for pressure booster pump, we recommend the installation of a check valve.

• When the pump is lowered to the bottom of the well, it must be suspended with the bottom edge of the

motor at least 30 cm from the well bottom. During operation the entire pump must be submerged below the

water level. If there is little water in the well, the pump can be installed in a horizontal position, but the

following must be observed:

1. Ensure sufficient well clearance

Loading...

Loading...