4. Unsolder

the

contacts

from

the

PCB.

Be

sure

that

the

contact

ends (protruding

through

the

Board) are actually free. This

is

important

when you are working on

double-sided Boards.

5. Note

the

position

of

both

types

of

con-

tacts.

The

fingered

contact

is

usually on

the

right side, with

the

keyboard

oriented

in

a normal position.

6. Using a pair

of

strong needle-nosed pliers,

pull

both

contacts

out

of

the

plastic base.

Fine

pointed

needle-nose pliers usually

cannot

grip

the

thin

contacts

well enough

for

extraction.

7. Insert a new

contact

set

in

tool #773-

10000

or

#773-10023, making sure

that

the

contact

fingers face each

other.

8. Insert

the

tool with

the

new

contacts

into

the

key base. Press

the

tool firmly until it

seats against

the

stops. Insure

that

the

PCB

is

not

resting

on

a hard surface because

the

tool will

try

to

force

the

contact

end

through

the

PCB.

9.

Extract

the

tool. Check

that

the

new con-

tacts

are

in

proper

position and

the

solder

ends

extend

through

the

PCB

on

the

oppo-

site side.

10. Solder

the

contacts. Replace

the

spring,

plunger, and keycap. Check

the

key for

proper

operation.

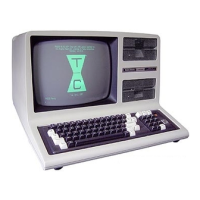

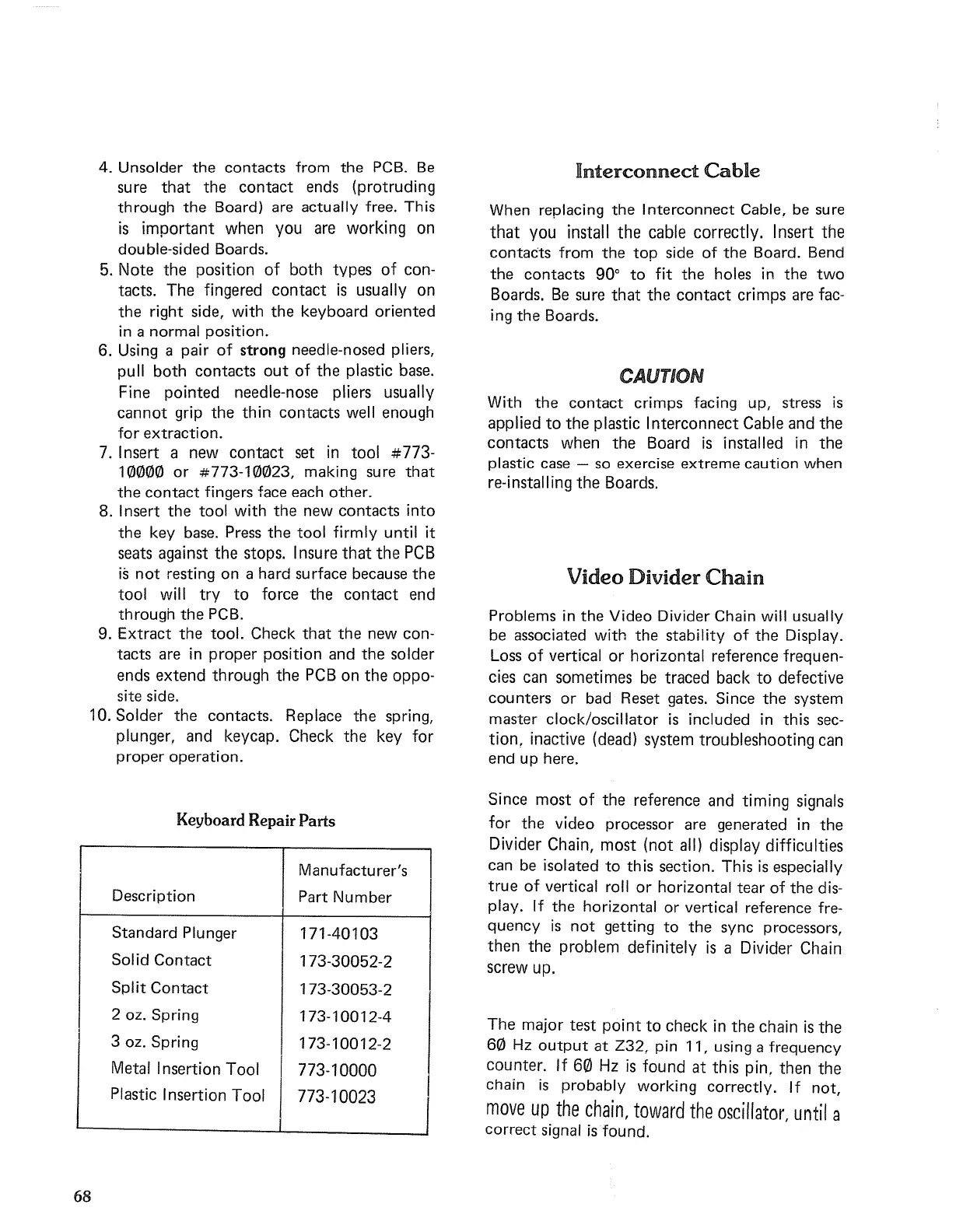

Keyboard Repair Parts

Manufacturer's

Description

Part

Number

Standard

Plunger

171-40103

Solid

Contact

173-30052-2

Split

Contact

173-30053-2

2

oz. Spring

173-10012-4

3

oz. Spring

173-10012-2

Metal Insertion Tool

773-10000

I

Plastic Insertion Tool

773-10023

68

Interconnect

Cable

When replacing

the

I

nterconnect

Cable, be sure

that

you install

the

cable correctly. Insert

the

contacts

from

the

top

side

of

the

Board. Bend

the

contacts

90°

to

fit

the

holes

in

the

two

Boards.

Be

sure

that

the

contact

crimps are fac-

ing

the

Boards.

CAUTION

With

the

contact

crimps facing up, stress

is

applied

to

the

plastic I

nterconnect

Cable and

the

contacts

when

the

Board

is

installed

in

the

plastic case - so exercise

extreme

caution

when

re-installing

the

Boards.

Video Divider

Chain

Problems in

the

Video Divider Chain will usually

be associated with

the

stability

of

the

Display.

Loss

of

vertical

or

horizontal reference frequen-

cies can sometimes be traced back

to

defective

counters

or

bad Reset gates. Since

the

system

master clock/oscillator

is

included

in

this sec-

tion.

inactive (dead) system

troubleshooting

can

end

up here.

Since

most

of

the

reference and timing signals

for

the

video processor are generated

in

the

Divider Chain,

most

(not

all) display difficulties

can be isolated

to

this section. This

is

especially

true

of

vertical roll

or

horizontal

tear

of

the

dis-

play. If

the

horizontal

or

vertical reference fre-

quency

is

not

getting

to

the

sync processors,

then

the

problem definitely

is

a Divider Chain

screw up.

The

major

test

point

to

check

in

the

chain

is

the

60

Hz

output

at

Z32, pin 11, using a frequency

counter.

If

60

Hz

is

found

at

this pin.

then

the

chain

is

probably working correctly. If

not,

move

up

the

chain,

toward

the

oscillator,

until

a

correct

signal

is

found.

Loading...

Loading...