TRAKFAST REPAIR MANUAL

65

Rev. 09/07

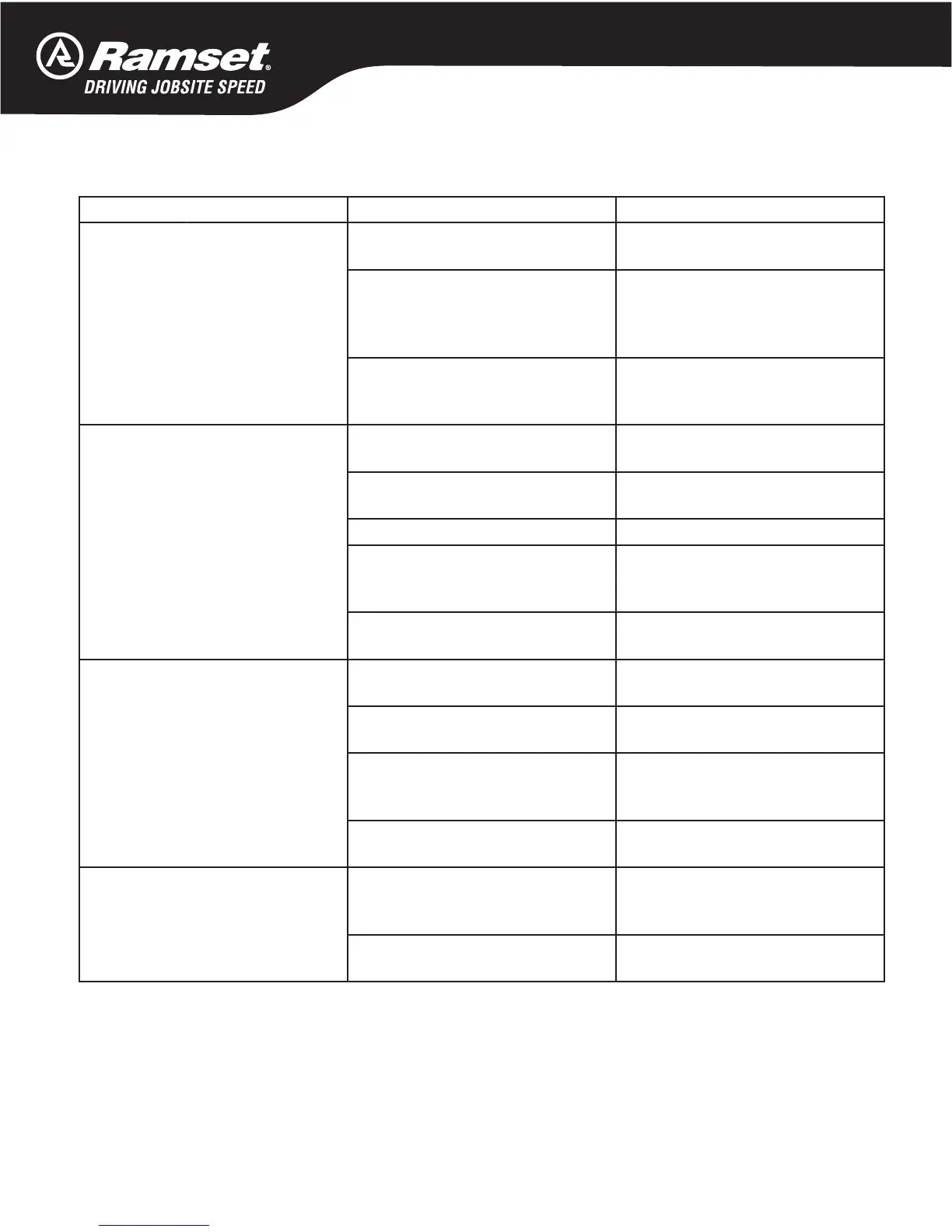

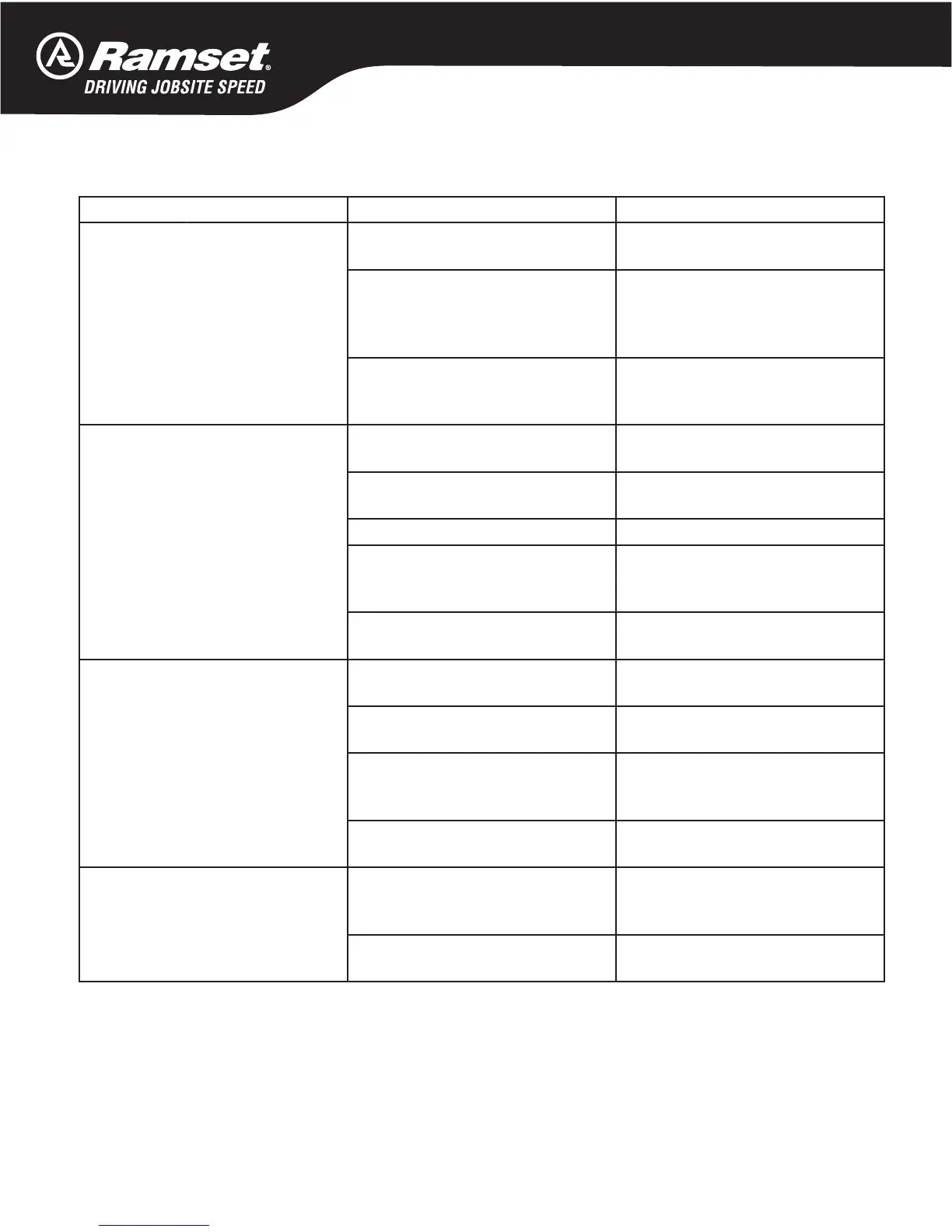

PRE-COMBUSTION/COMBUSTION STAGE OF OPERATION

Symptom Possible Problems Service

Work Contact Element (WCE) doesn’t

go down all the way – tool does not

operate.

WCE is bent or build-up of dirt in

track restricts operation.

Remove and inspect WCE. Replace

WCE as required.

Cylinder Head O-Ring is dry or not

seated in groove properly.

Lubricate Cylinder Head O-Ring with

TrakFast Lubricating Oil or replace

O-Ring if O-Ring does not seat in

groove.

Upper Sleeve O-Ring is dry or not

seated in groove properly.

Lubricate O-Ring with TrakFast Lubri-

cating Oil or replace O-Ring if O-Riing

does not seat in groove.

Tool won’t operate – Fan runs, LED is

constant green. No spark apparent.

Battery Cell charge is marginal or

contacts and terminals are dirty.

Recharge Battery Cell and clean

contacts.

Spark Plug wire is not connected

properly.

Install spark plug wire.

Spark Plug is dirty or damaged. Clean or replace Spark Plug.

Trigger Switch is improperly installed

or inoperative.

Check switch for proper operation.

Repair or replace as necessary. Check

connection at MSU Spark Unit.

Spark Unit is inoperative. Check and replace MSU Spark Unit as

required.

Tool won’t operate. Fan does not run,

LED blinks green.

Spark Unit is inoperative. Check Spark Unit for spark. Replace

if bad.

Head Switch is inoperative. Check Head Switch and connections.

Replace as necessary.

Cage is deformed or bent. Check Cage for bent arms or de-

formed base. Repair of replace as

necessary.

Grommet in Upper Probe is damaged

or missing.

Check and replace Upper Probe as

necessary.

Tool won’t operate – Fan runs, LED is

constant green, audible spark appar-

ent but not visible at Spark Plug.

Spark Plug wire shorting to ground at

Cylinder Head Casting.

Make sure Plug wires correctly seated

into Spark Plug. Replace Spark Plug

wire as necessary.

Spark Plug is fouled, causing spark to

ground out to Cylinder Head.

Clean Spark Plug gap and Cylinder

Head.

TROUBLESHOOTING GUIDE

Loading...

Loading...