TRAKFAST REPAIR MANUAL

66

Rev. 09/07

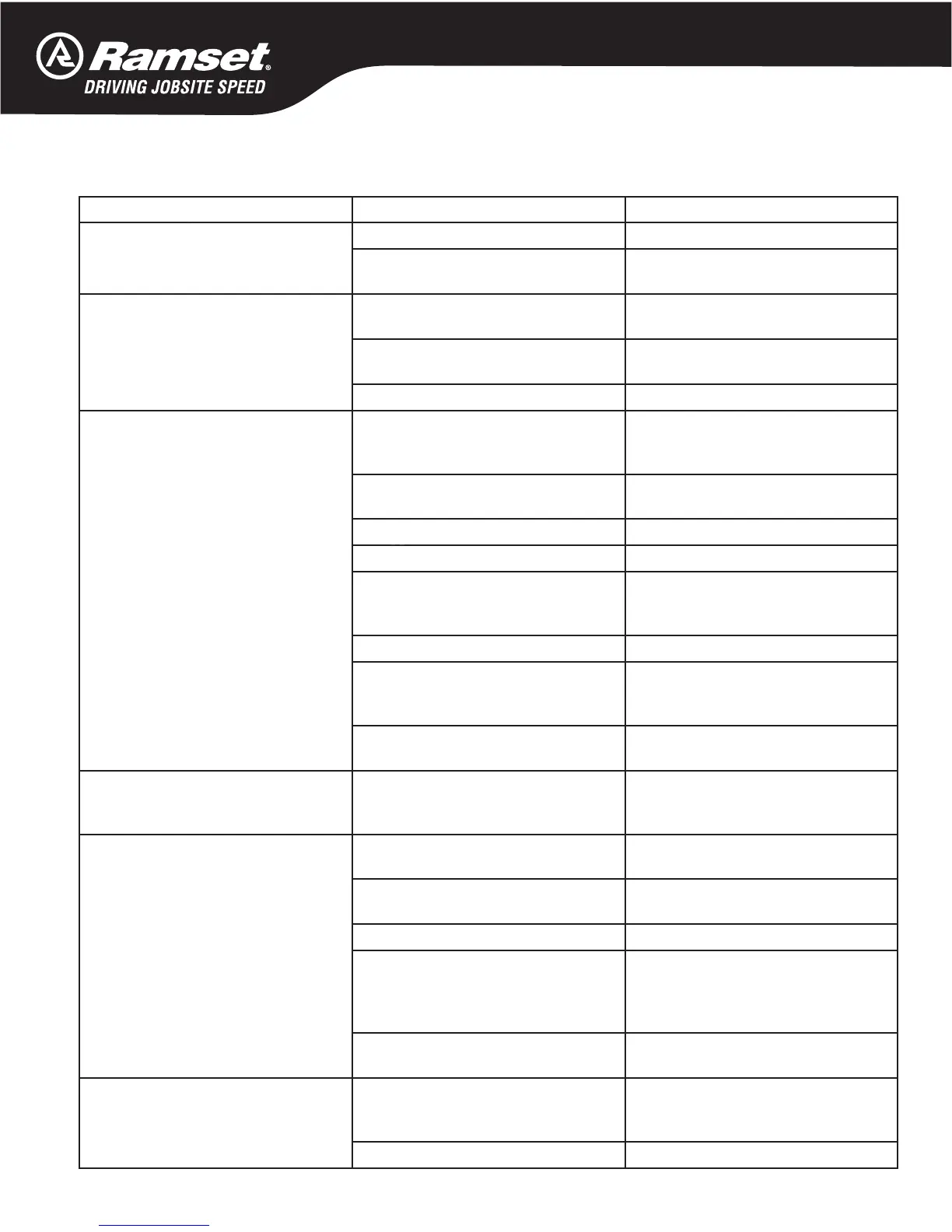

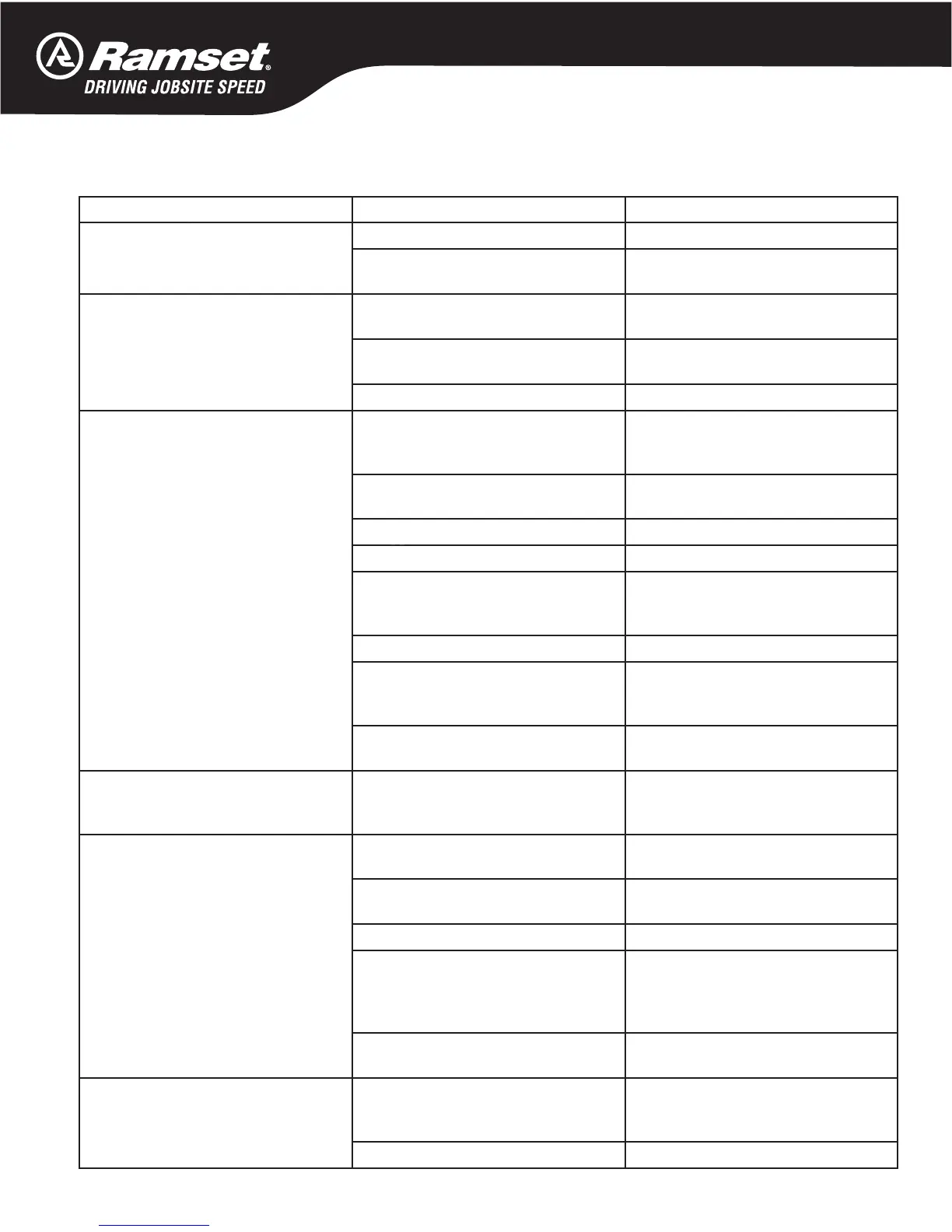

TROUBLESHOOTING GUIDE

POWER/EXHAUST STAGE OF OPERATION

Symptom Possible Problems Service

Tool works properly, but pins won’t

drive fully.

Check application. Check application.

Fuel Cell is low. Check Fuel Cell according to Owner’s

Manual.

Tool works properly, but pins are

consistently under-driven.

Bumper is not seated properly in base

of Sleeve.

Seat Bumper properly.

Driver Blade broken at tip or worn

excessively.

Replace Piston Assembly.

Driver Blade loose at Piston. Replace Piston Assembly.

Tool operates, but doesn’t drive pins. Follower not properly engaged behind

pin strip.

Locate Follower behind pin strip and

engage strip according to instructions

in Owner’s Manual.

Jammed fastener. Clear jam by removing Magazine ac-

cording to Owner’s Manual.

Burr(s) in Shear Block Replace Shear Block.

Burr(s) in Upper or Lower Rail. Replace Upper and/or Lower Rail.

Piston not fully returning. Check O-Rings, check Flat Washer,

check Wavy Washers. Replace as

necessary.

Driver Blade loose at Piston. Replace Piston Assembly.

Follower Constant Force Spring im-

properly installed, damaged, dirty or

weak.

Replace Constant Force Spring.

Shear Block is loose, preventing pin

feed into nose of tool.

Apply Loctite #242 (blue) to all Shear

Block Screws and tighten securely.

Tool works, but pin is driven at an

angle into concrete or deflects off

work surface.

Driver Blade broken at tip or worn

excessively.

Replace Piston Assembly.

Tool works erratically, LED is constant

green.

Battery Cell charge is marginal. Charge Battery Cell according to

Operator’s Manual.

Fuel Cell is low. Check Fuel Cell according to Opera-

tor’s Manual.

Spark Plug wire is loose. Check Spark Plug wire.

Filter elements are dirty, causing tool

to overheat.

Remove Filter elements and clean

according to Operator’s Manual. Use

safe cleaning solution to remove stub-

born debris.

Battery Contact Assembly is damaged

or dirty.

Replace Battery Contact Assembly.

Tool won’t work as fast as normal;

operator must slow pace or tool won’t

cycle.

Filter elements are dirty, causing tool

to overheat.

Remove Filter elements and clean

according to Operator’s Manual. Use

safe cleaning solution if necessary.

Tool Sleeve is dirty. Clean Sleeve/Mid-Check Assembly.

Loading...

Loading...