TRAKFAST REPAIR MANUAL

67

Rev. 09/07

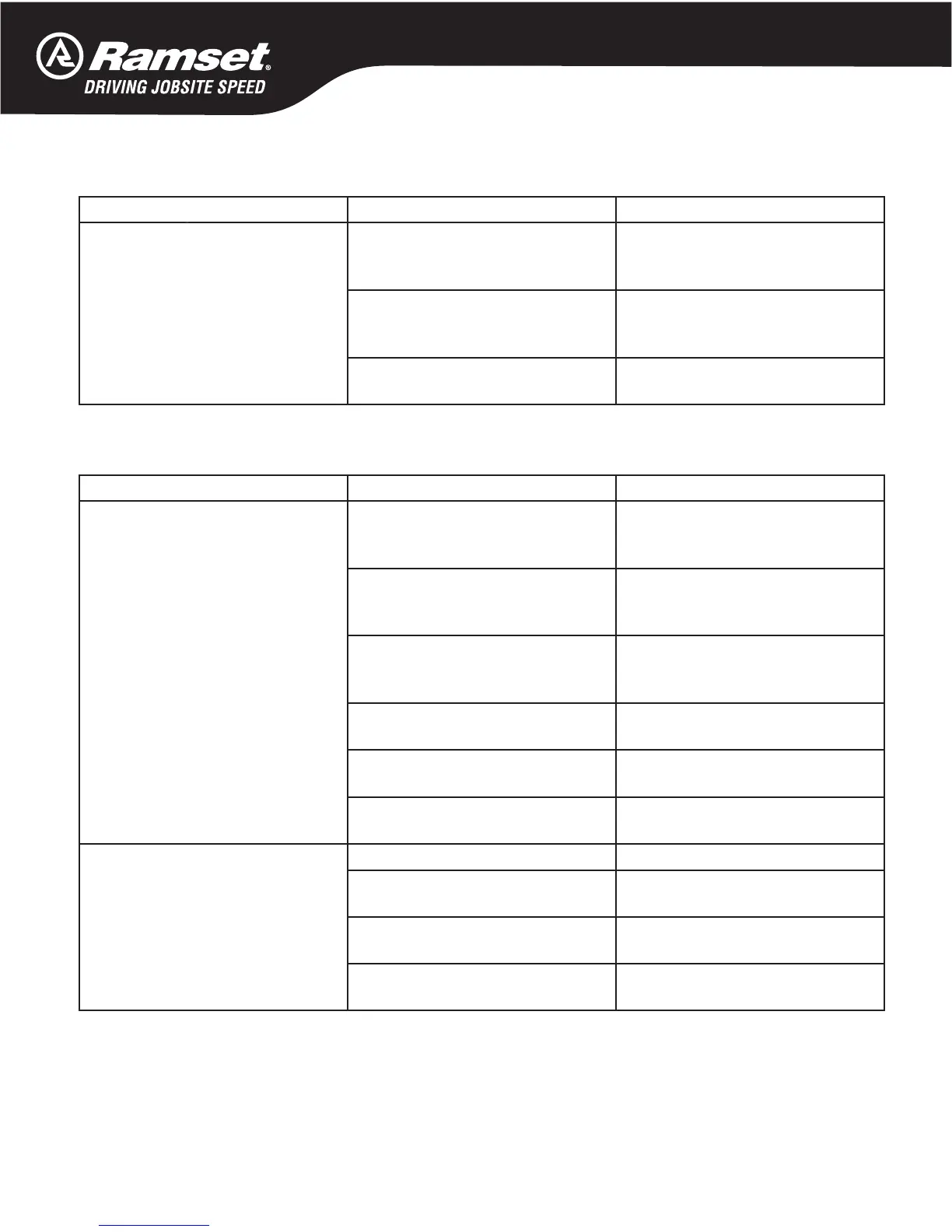

Symptom Possible Problems Service

Tool cycles with a “poof” sound – no

pin is driven.

Piston Rings are damaged or not

seated properly in piston ring

grooves.

Check Piston Rings and service as

required.

Piston Retaining Ring is damaged,

missing, or not seated properly in

groove.

Check Piston Retaining Ring and

serve as required.

Sleeve or Cylinder Head O-Ring is

broken or damaged.

Check Sleeve or Cylinder Head O-

Ring and service as required.

POWER/EXHAUST STAGE OF OPERATION (cont’d)

RETURNING/PURGING STAGE OF OPERATION

TROUBLESHOOTING GUIDE

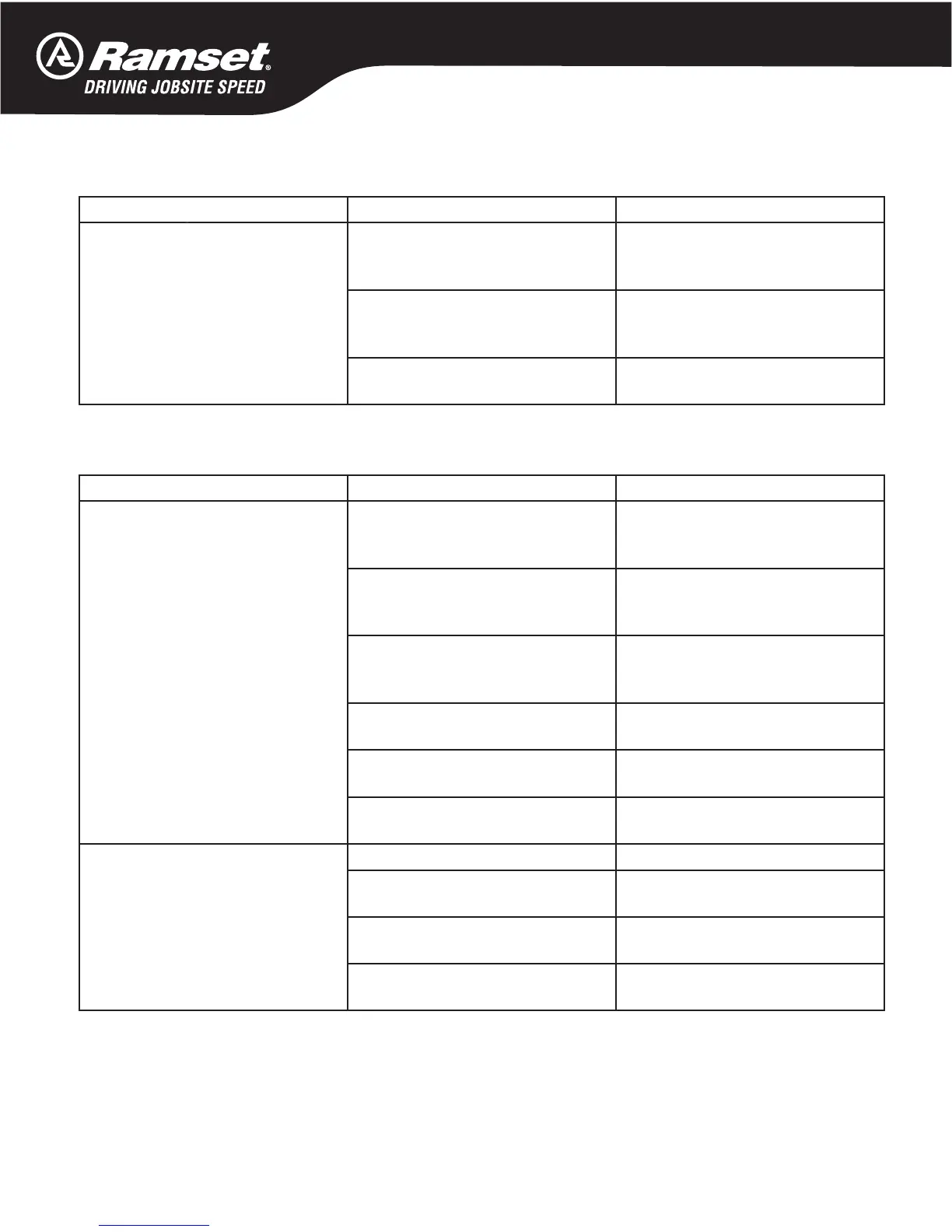

Symptom Possible Problems Service

Tool drove pin, but Piston Assembly

won’t return to up position.

Build-up of dirt and debris on Driver

Blade in Nose bore.

Clean Piston Assembly and Nose bore

with safety solvent and lubricate with

TrakFast Lubricating Oil.

Piston Rings are dirty, preventing

full contact with sleeve walls, or are

damaged.

Check Piston Rings for free-floating

engagement in Piston grooves, and

clean or replace.

Combustion Chamber O-Rings are

dry, damaged, or swollen, preventing

vacuum seal from being held.

Lubricate or replace O-Rings.

Mid-Check Seal Washer is dirty, bent

or damaged.

Check Seal Washer and clean or

replace.

Mid-Check Wave Washers are dam-

aged (flattened).

Replace Wave Washers.

Debris in Mid-Check area is prevent-

ing proper operation of Mid-Check.

Check Mid-Check area for debris or

Bumper for fragments and clean.

Combustion Chamber won’t drop

when Trigger is released after tool

cycles.

WCE is burred or damaged. Replace Work Contact Element (WCE)

Head O-Ring is dry, damaged or

swollen.

Check Head O-Ring and Lubricate or

replace.

Combustion Chamber O-Rings are

dry, damaged or swollen.

Check Combustion Chamber O-Rings

and lubricate or replace.

Air Dam is pinched between Housing

and casting.

Re-seat Air Dam.

Loading...

Loading...