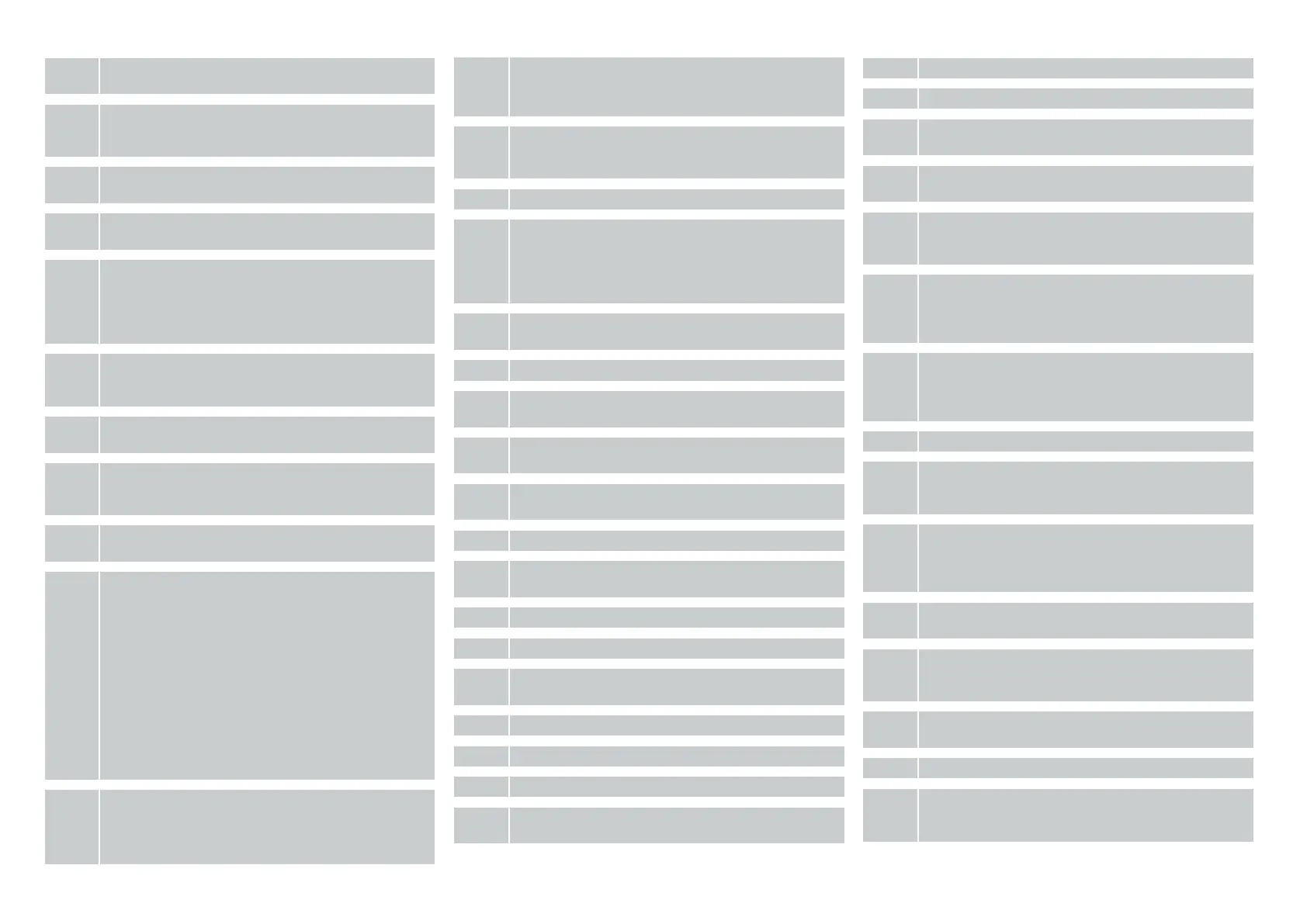

| SERVICE REFERENCE iCombi

19.X

x= type of error -1= EEPROM missing or not recognised;

-2 = internal storage error (battery may have been removed)

20.X

Thermocouple break, x= sensor: -1 Cooking cabinet B1; -2

Control sensor B2; -4= humidity B4; -8= Steam generator

B5; -9: Thermocouple B9 faulty - only floor units

23

Temperature rise on the steam generator without request

Steam heating check

24

Temperature rise in the cooking cabinet without request

Hot air heating check

25

No water detection without cleaning

Fan wheels do not run / no increase in performance at the

fan motor when the water jet hits: Check water supply, pres-

sure, hoses, CDS sensor, position of GN conductors and mo-

bile oven racks

28.x

Thermocouple, x= Sensor: -1: SG B5 too hot (>170°C); -2:

Cooking cabinet B1 too hot (>350°C); -4: Steam generator

B5 too cold (<2°C, heating possible again from 4°C)

29.x

PCB temperature too high: -1: motor down; -2: motor

centre; -4: Pump PCB; -16: I/O PCB -64: CPU PCB

30

Humidity measurement not working correctly

Pressure sensor P1, connection hoses, measuring connec-

tion pieces, humidity sensor B4

31.xx

Thermocouple core temperature B3; x = error type: -1: core

probe error; -11: external core probe error

32.x

Fault in combustion system or gas supply,

x= fault, y= combustion system

-1.y (22= HA top, 32= steam, 42= HA bottom):

5x unsuccessful ignition process

-2.y (17/18/49= HA top, 27/28/52= steam, 37/38/55=

HA bottom):

Flame current measured with gas valve closed

-3.y (19= HA top, 29= steam, 39= HA bottom):

Burner goes out 5 times during the burning phase

-4.y (20= HA top, 30= steam, 40= HA bottom):

The speed of the gas blower deviates from the target speed

by more than 150 rpm

33.x

Error in the control of the combustion system, x= error

-1: Ignition box fault accumulation

-2: Desired gas speeds breach condition >0 rpm or Min. <

Start < Max.

-3: Mains frequency outside 40…70 Hz

-4: Phase and neutral conductor mixed up

-5: Automatic ignition controller error

34.xx

Bus signal missing:-1 motor top; -2 motor centre; -4 motor

bottom (floor units only); -8 Pump PCB; -16 I/O power

supply; -32 ignition box;

35

UltraVent: Bus signal / internal communication

35.x

UltraVent error: -1 voltage missing; -2 Filter detection faulty

(UV Plus only); -3 Thermocouple control error; -4 Thermo-

couple motor protection error; -5/6 Dirt in filter (pre-warn-

ing/immediate replacement); -7 Filter not inserted/no dif-

ferential pressure measured

36

Differential pressure sensor fault (no signal output of 0.5V;

check 12V at P1); P1 must be installed horizontally

37

Climate control malfunction: Check connecting hoses

40

Check the care pump (M18) in the function test (note: Y4 is

activated at the same time, run the rinse programme)

42.x

Solenoid valve x does not open: -1: fill Y1; -2: control Y2; -4

Care Y4; -5 Climate Y5/Y15

43.x

Solenoid valve x does not close: -1: Fill Y1; -2: control Y2; -4

Care Y4; -5 Climate Y5/Y15

44

Steam heating faulty or inadequate during cleaning

46.x

SC pump (M4); x= type of error: -1: defective; -2: Output too

low

47

Wastewater pump (M15); -1: defective; -2: Output too low

48

Circulation pump (M17); -1: defective; -2: Output too low

49

Care pump (M18); x= type of error: -1: defective; -2: Output

too low

50

Real time clock (date and time) not initialised

51

Check battery, replace if necessary

52

LED cooking cabinet light faulty

63

Water detected after dry calibration, repeat self-test with

water

64

Unit calibrated dry– attempt to start humid cooking mode

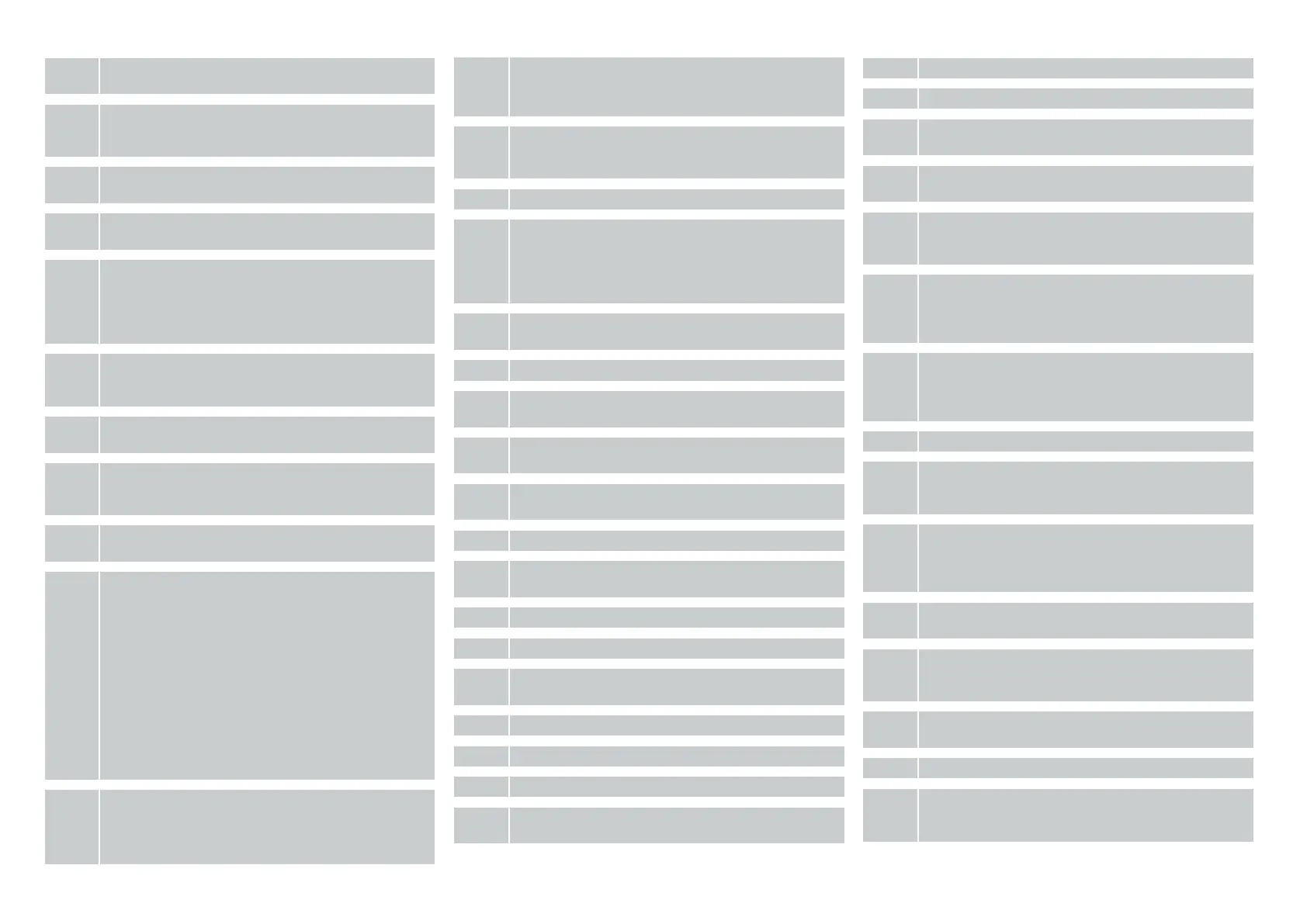

70

Cooling fan error

71.X

Power supply fault -1: General failure; -2: Undervoltage

(<170V)

72

eSTB for HA or steam: Blink code on eSTB – error code, see

description below

73.x

Fault due to overtemperature on: -1 Motor top; -2 Motor

bottom; -4 Motor centre; -8 Pump PCB; -16 Ignition box;

-32 I/O power supply

75.x

Internal bus interface: -1: Additional PCB energy optimiza-

tion not detected; -2: Additional PCB 4-way relay is not de-

tected,

-4 (USA ONLY) voltage switching PCB is not detected

76.xx

USA units ONLY

Error voltage switching PCB -1: Voltage too low; -2: Internal

check failed; -3 incorrect voltage setting 4 to -7: Internal er-

ror

90

Unit not yet calibrated, carry out calibration

110

SC pump faulty while care solution is in the steam generator

(Remove error and set to released under Basic settings

"Cleaning unlock")

120

Level electrode without signal while care solution is in the

steam generator

(Remove error and set to released under Basic settings

"Cleaning unlock")

121

Additional function when operating the unit without water:

Note on filling water into the control box

140

Permanent fault in the gas supply or in the hot air gas com-

bustion system; -4 Pre-warning for cooking operation

block; -8 Cooking operation block

200

Automatic motor positioning failed

(mostly followed by error 201)

201

Carry out motor positioning

900.xx

-8: Initialise date and time failed; -16: Battery empty or re-

moved; -32: Data loss due to battery voltage; -48: Battery

removed, unit data and clock initialisation incorrect (sum-

80.51.885 RTS/Bret V06.2 - 01/24 en-GB 2 / 3

Loading...

Loading...