43

5. Turn power off.

6. Reinstall rubber plug on tee.

Main Burner Adjustment

1. Turn off unit.

2. Open manual firing valve.

3. Turn on the unit, wait 15 seconds, and the igniter

should glow. There’s a sight glass to check igniter

at both ends of the heater. Gas valve should be

open after 45 seconds.

4. If burner does not light on first trial. It will retry, up

to 3 times.

5. Main burner ignition – check manifold gas pres-

sure at gas valve manifold pressure tap. (See

Table P).

6. If the pressure reading differs by more than the tol-

erance given, adjust the gas valve accordingly.

See gas valve adjustment section below for

instructions.

Gas Valve Adjustment

Honeywell Gas Valve

1. While the heater is running, remove plastic cap

located behind ON/OFF knob.

2. Locate the HI or LO screw to adjust.

3. Using a small flat screwdriver, turn clockwise to

increase and counterclockwise to decrease mani-

fold pressure. See nominal gas valve manifold

settings in Table P above.

4. Replace plastic cap when pressure is set.

White Rodgers Gas Valve

1. While the heater is running, locate the HI or LO

cap located adjacent to ON/OFF switch.

2. Remove the appropriate cap.

3. Using a flat screwdriver, turn clockwise to increase

and counterclockwise to decrease manifold pres-

sure. See nominal gas valve manifold settings

above.

4. Replace cap(s) when pressure is set.

Invensys (Model HD401 Natural

Only)

1. Turn heater off.

2. Locate and remove the Torx tamper resistant

screw. (Shown in Fig. 35)

3. Carefully remove 2-stage solenoid.

4. Skip to Step 9 for LO-fire adjustment only.

5. Locate and remove Lo-fire adjustment cap.

6. Carefully remove the spring & weight.

7. Using an allen wrench, turn clockwise to increase

and counterclockwise to decrease the HI-fire man-

ifold pressure. Heater will not run while adjusting

HI-fire pressure.

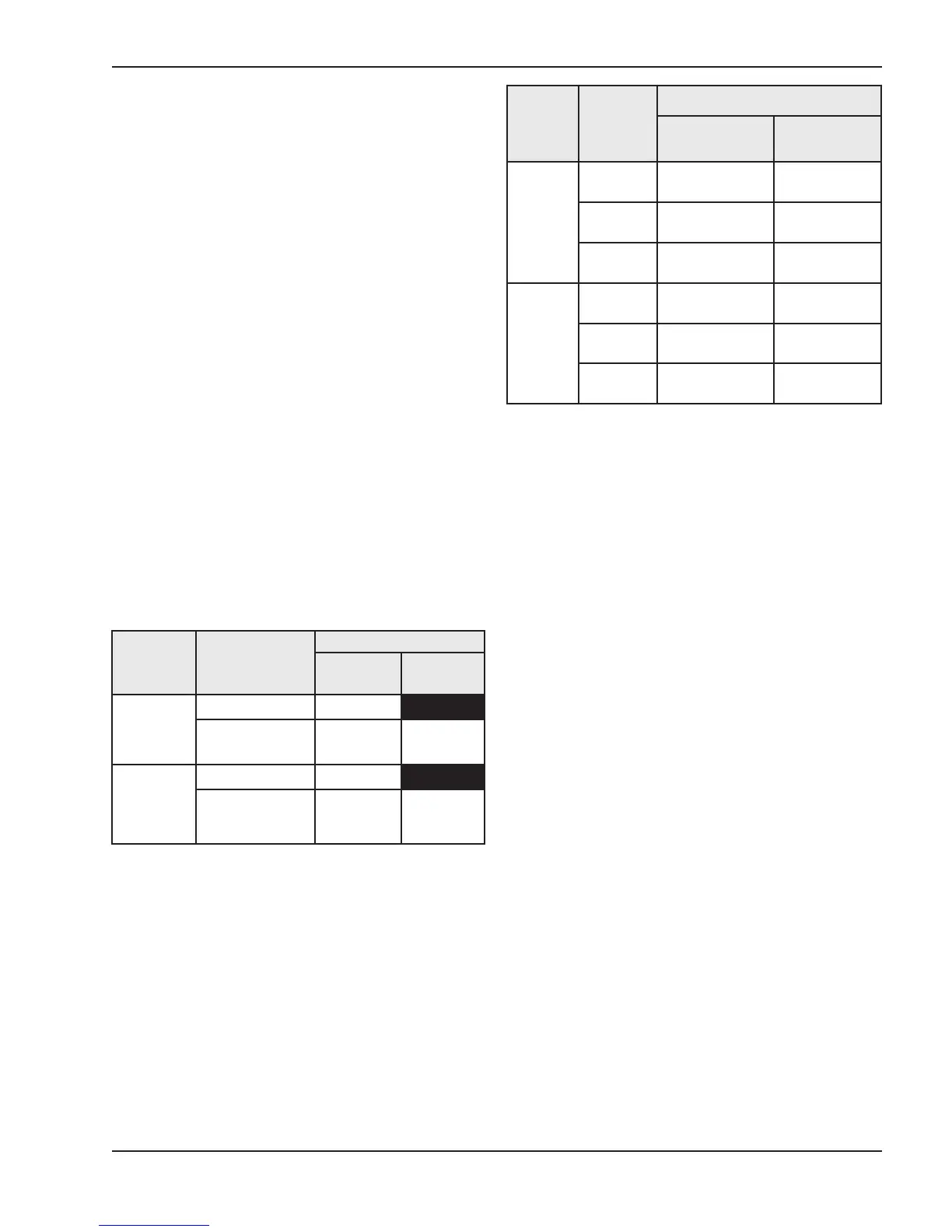

Table P: Gas Valve Pressures

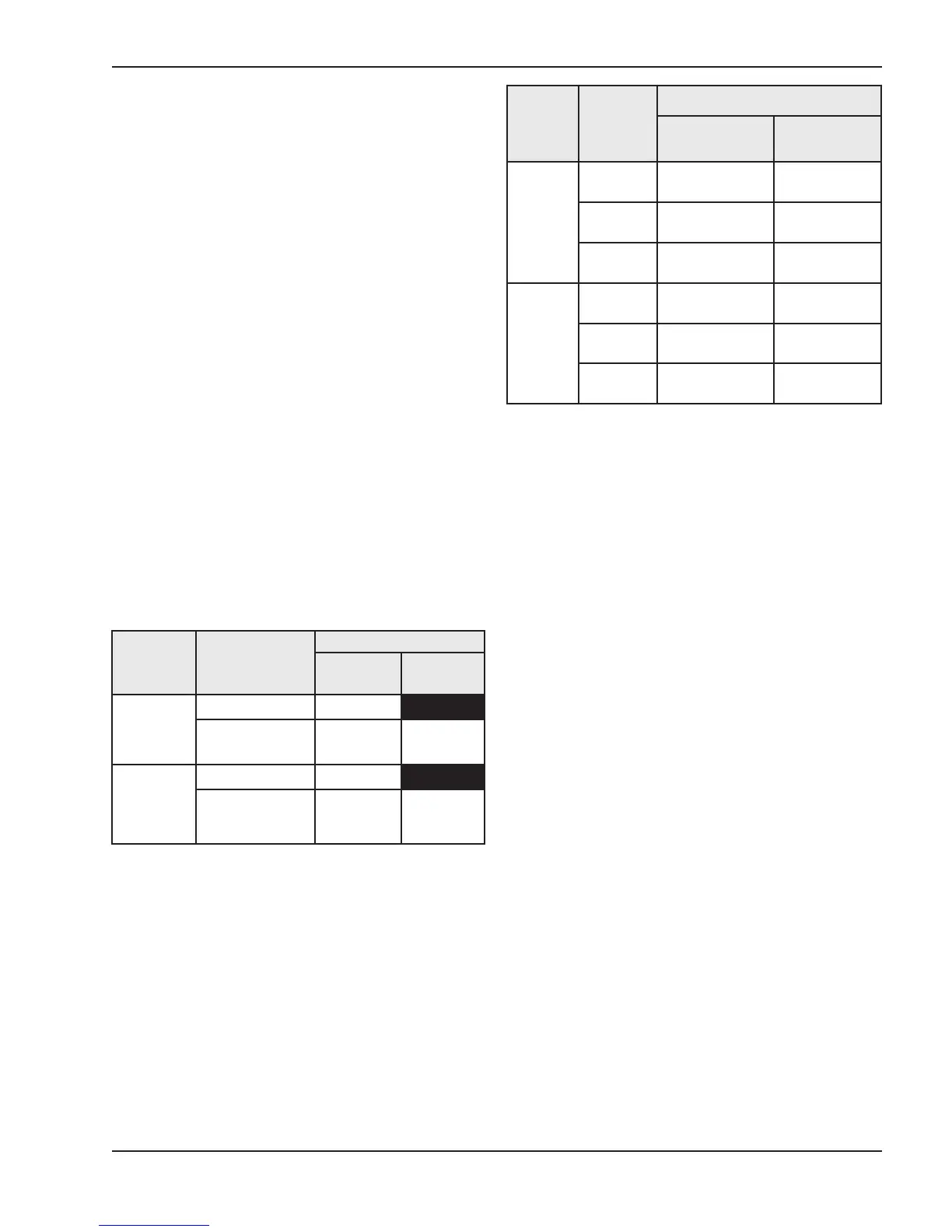

Table Q: Expected Settings

Firing

Stage

Gas Valve

Gas Type

Natural

LP/

Propane

Hi-Fire

+/- 0.2"WC

Invensys 3.4" WC

Honeywell or

White-Rodgers

3.1" WC 9.6" WC

Lo-Fire

+/- 0.1"WC

Invensys 1.1" WC

Honeywell or

White-Rodgers

1.2" WC 3.6" WC

F

iring

Stage

E

xpected

Settings

Gas Type

Natural

LP/

Propane

Lo-Fire

C

O2

8

.2 +/- 0.2%

9

.7 +/- 0.3%

CO < 50ppm < 50 ppm

Air

0.45” +/- 0.05”

WC

0.45” +/- 0.05”

WC

Hi-Fire

CO2 8.7 +/- 0.2% 10.1 +/- 0.4%

CO < 100ppm < 100ppm

Air

1.05” +/- 0.1”

WC

1.05” +/- 0.1”

WC

Loading...

Loading...