18

To remove the revolving centre from the tailstock spindle insert the knockout

bar into the hole in the centre of the tailstock hand wheel and give the

revolving centre a sharp knock to dislodge it from the tailstock, see Fig

11.11.

Adjusting the Tool Rest

To move the tool rest across the lathe bed, loosen the tool rest holder locking

lever, slide the tool rest holder to the desired position and tighten the locking

lever.

To adjust the height of the tool rest loosen the tool rest locking lever,

position as required and re-tighten, Fig 11.12.

Adjusting the Tailstock

Loosen the tailstock locking lever to move the tailstock along the lathe bed

to the desired position and tighten the lever, Fig 11.13.

To adjust the tailstock spindle position, loosen the tailstock spindle locking

lever and turn the hand wheel. When the tailstock spindle is in the desired

position, re-tighten the locking lever, Fig 11.13.

Adjustment of the Clamping Action of the Tool Rest Holder

and Tailstock

If the movement of the tool rest holder or tailstock is unsatisfactory, either

due to being too stiff and difficult to move or too easy to move and giving

inadequate locking, the clamping action can be adjusted. Please see the

Maintenance section of the manual for full details.

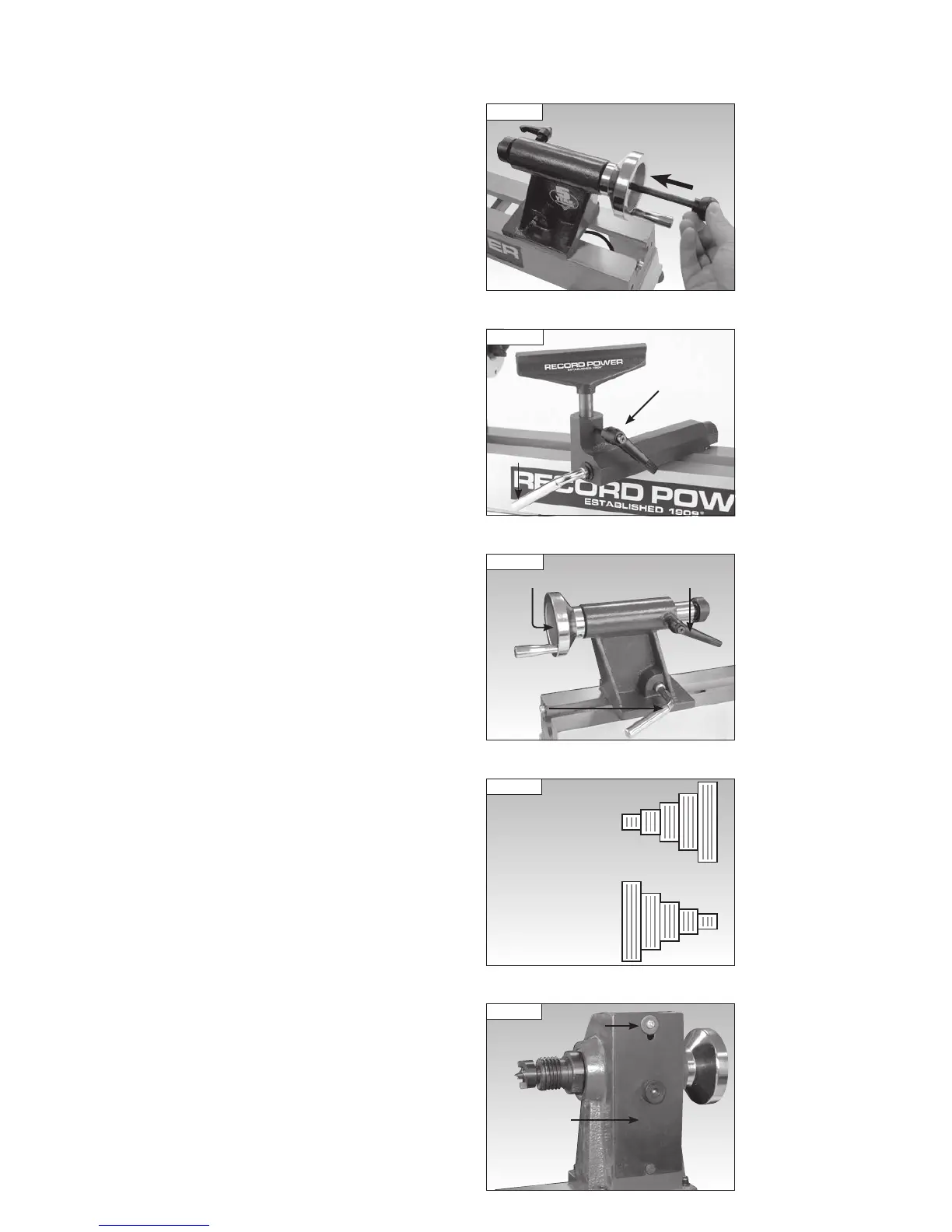

Changing the Spindle Speed

The DML250 features a 5 step pulley system. The drive belt must be

positioned on the corresponding pulleys as shown in Fig 11.14 to achieve

the speeds shown.

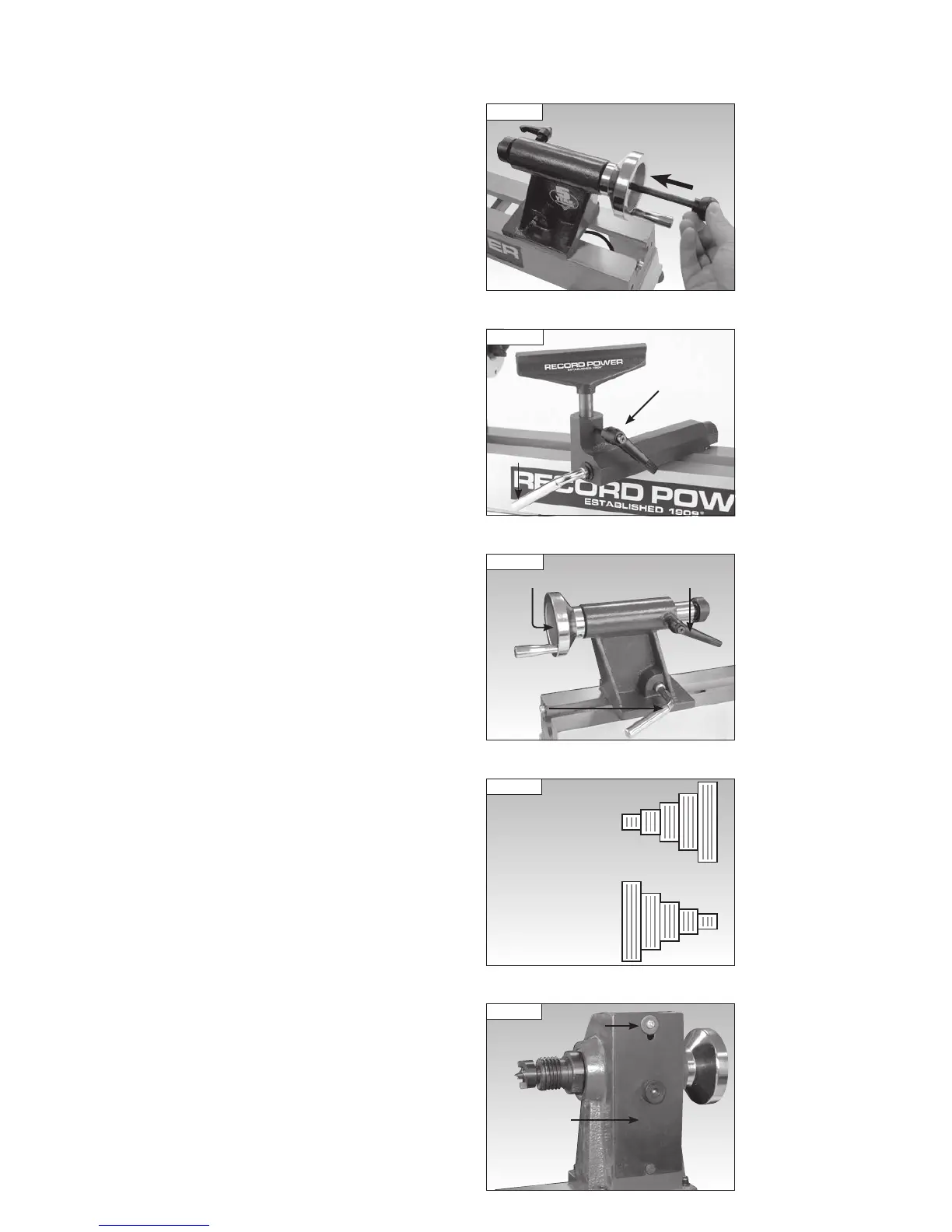

To access the spindle pulley, remove the cross head screw and washer from

the headstock cover using a cross head screwdriver (not supplied), and

remove the cover, Fig 11.15.

11. Operation

Fig 11.11

Fig 11.12

Tool rest

locking

lever

Tool rest

holder

locking

lever

Fig 11.13

Tailstock spindle

locking lever

Tailstock

locking

lever

Hand wheel

Fig 11.15

Headstock

cover

Screw and

washer

Fig 11.14

Pulley

Speed

Ranges

Spindle Pulley

Motor Pulley

450 rpm

980 rpm

1550 rpm

1940 rpm

2640 rpm

Loading...

Loading...