23

12. Maintenance

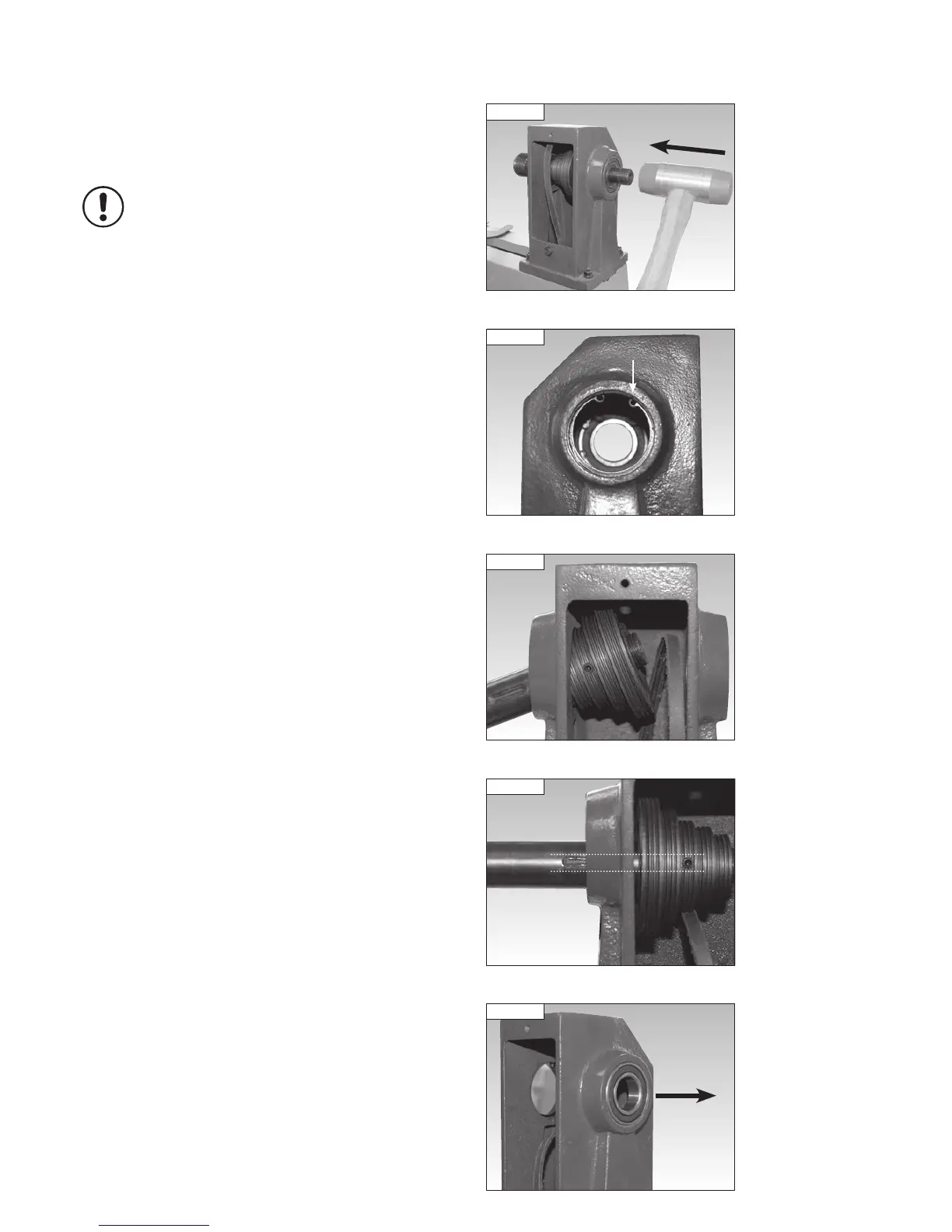

Once the spindle pulley is loose, carefully knock the spindle out of the

headstock using a soft headed mallet as shown in Fig 12.11 by knocking

firmly towards the tailstock end.

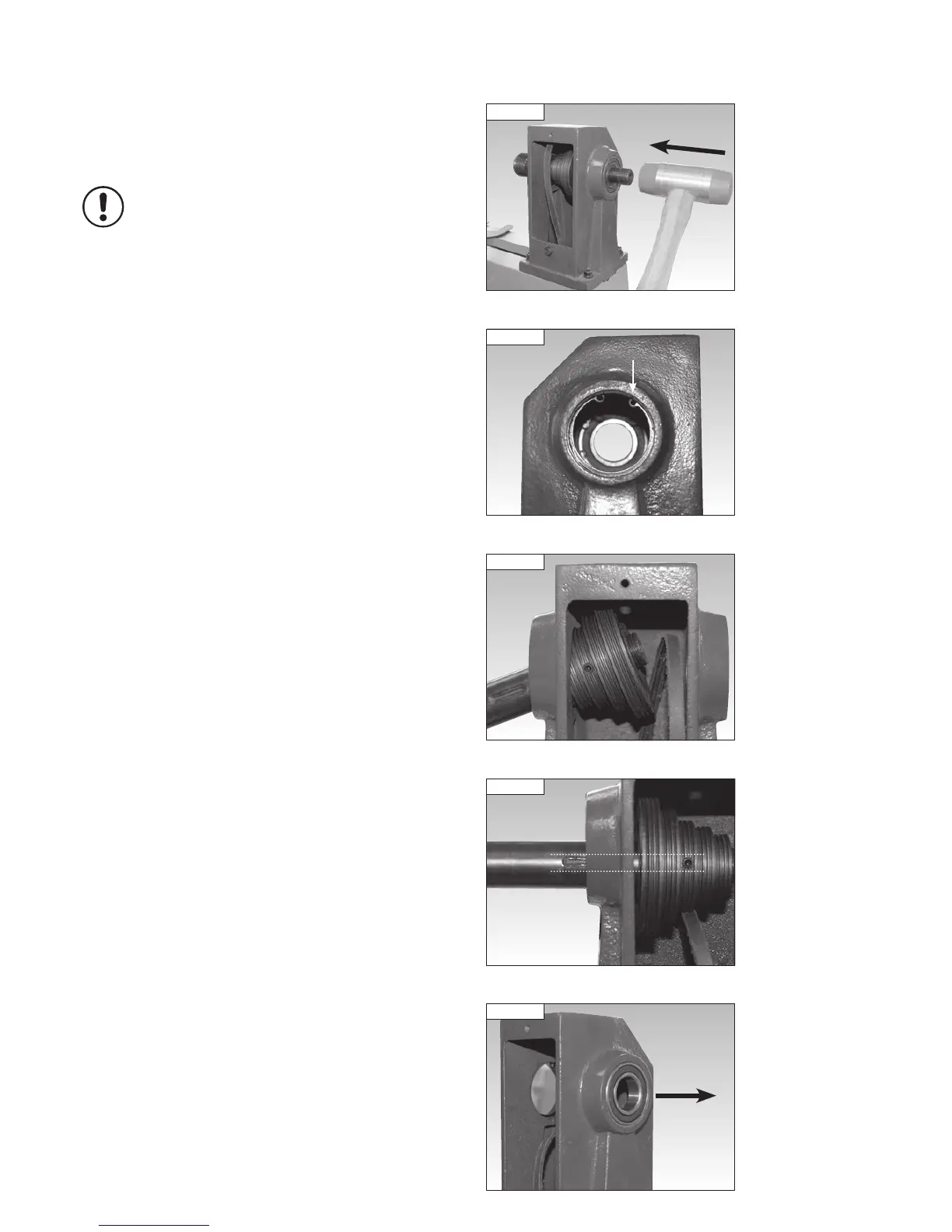

Please note: The headstock features a circlip inside each recess

that houses the bearings as shown in Fig 12.12. The purpose of

these circlips is to retain the bearings in the correct position and

they must not be removed.

When the spindle is loose, the old belt can be removed and replaced, Fig

12.13, before re-installing the pulley and spindle to the headstock.

When re-attaching the pulley to the spindle, ensure that the recessed area

of the spindle is aligned with the blind set screw of the pulley to ensure

maximum hold, as shown in Fig 12.14.

Replacing the Bearings

To remove the old bearings, remove the upper spindle as previously described.

This will leave the bearings in the headstock free for removal.

Using a soft mallet, carefully but firmly knock each bearing out of the

headstock from the inside so the bearings are pushed out of the headstock,

Fig 12.15.

Once removed, replace with new bearings and re-assemble the headstock.

Fig 12.13

Fig 12.12

Circlip

Fig 12.14

Loading...

Loading...