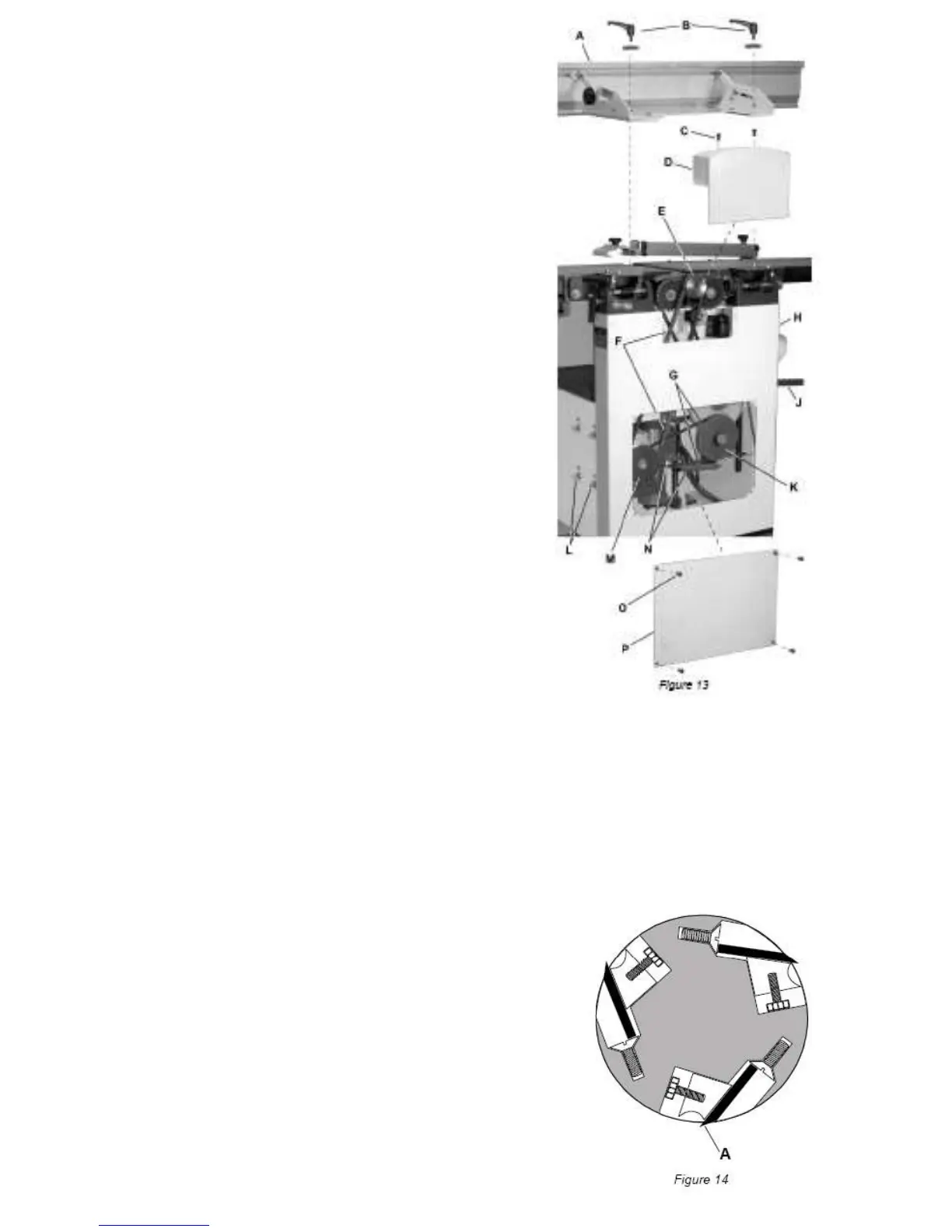

2. Remove two button head socket screws (C)

and upper back panel (D).

3. Remove four button head socket screws (O)

and lower back panel (P).

Cutterhead Drive Belt Replacement

4. Loosen four motor mount screws (L). Lift the

motor and rest it in the horizontal slot side of

the motor mount opening. This will create a

slack in the cutterhead drive belt (F).

5. Remove the cutterhead drive belt (F) from

around the cutterhead pulley (E) and motor

pulley (M).

6. If the feed-roller belt (K) is to be replaced,

continue. Otherwise proceed to step 10.

Feed-roller Belt Replacement

Note: If the feed-roller belt is to be replaced, steps

1–5 must be performed to remove the cutterhead

drive belt before the feed-roller belt can be

replaced.

7. Place the power feed handle (J) in the down

(off/disengaged) position, which provides belt

slack for the next step.

8. Remove the feed-roller belt (G) from around

the feed-roller pulley (K) and motor pulley (M).

9. Loop the new belt around the smaller (inner)

motor pulley (M) and feed-roller pulley (K).

Note: The lower stretch of the feed-roller

pulley must be positioned between the beltbrake

plates (N).

Concluding Steps

10. Replace the cutterhead drive belt (F) by looping it around the cutterhead pulley (E), then the

larger (outside) motor pulley (M).

11. Slide the motor so the mounting screws (L) rest back in the vertical slot openings, then tighten

the mounting screws.

12. Replace the lower back panel (P) and secure with four button head socket screws (O).

13. Replace the upper back panel (D) and secure with two

button head socket screws (C).

14. Replace the jointer fence assembly (A) and secure with

two lock handle assemblies (B).

Planer Table Adjustment

Disconnect machine from power source before making any

adjustments.

Failure to comply may cause serious injury.

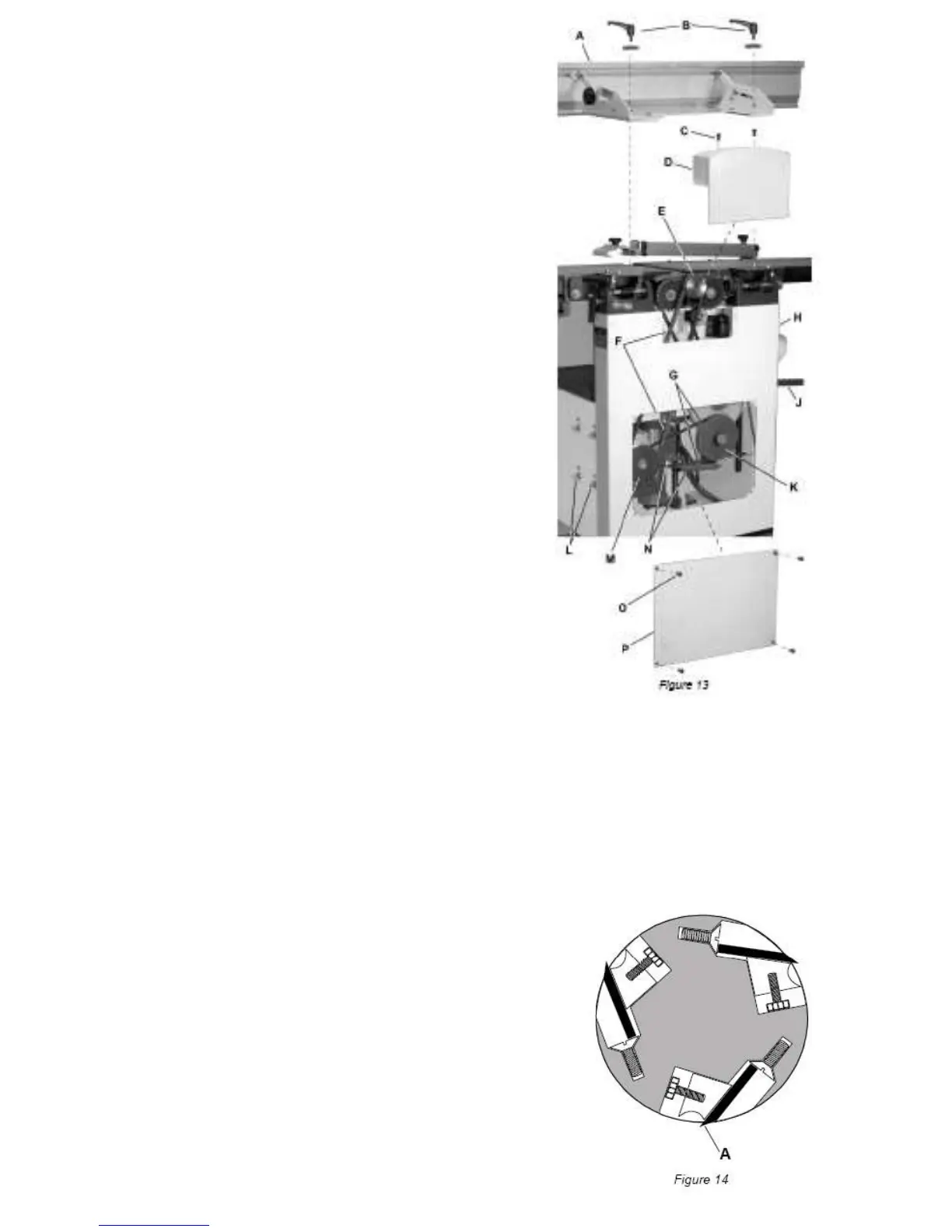

Checking Planer Table Parallel to Cutterhead

The planer table is set parallel to the cutterhead at

Loading...

Loading...