50

Setting options:

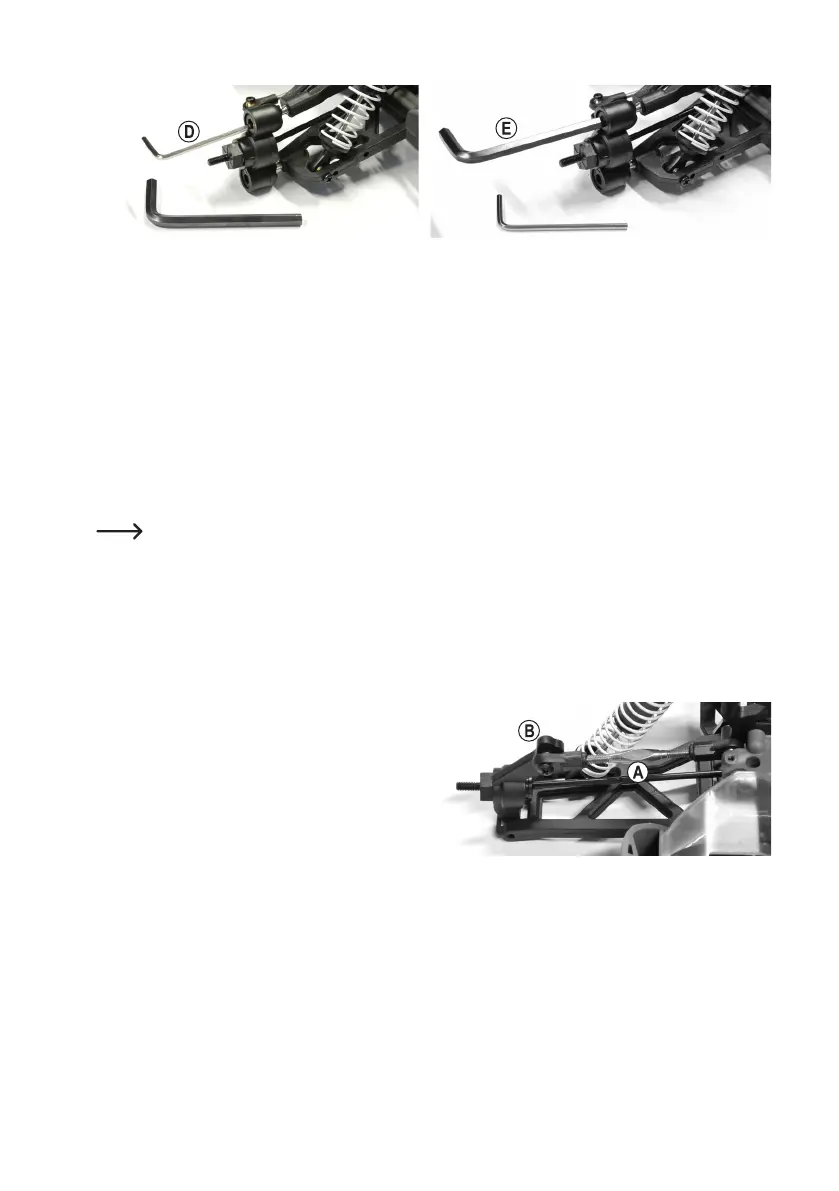

• To adjust the wheel camber, twist the metal ball-head screws with a small 2.5 mm hexagon wrench (D).

• In order to tighten the plastic grub screws (or to release them), twist them with a larger 5 mm hexagon wrench (E).

As described already, they must be adjusted so that the metal ball-head screws in the axis stub can move easily

without wobbling.

Set camber more negatively:

Turn the upper ball-head screw (A) to the right clockwise, and the lower ball-head screw (B) to the left counter-

clockwise at the same angle.

Set camber more positively:

Turn the upper ball-head screw (A) to the left counter-clockwise, and the lower ball-head screw (B) to the right clock-

wise at the same angle.

Twist the ball-head screws (A) and (B) via the small hexagon wrench (D) only by one quarter and then

check the changed driving conduct.

The small hexagon hole of the ball-head screws (A) and (B) is only visible when looking right through the

large hexagon hole of the plastic grub screws (C).

Do not turn out the ball-head screws too far. Else, the drive axis may fall out (or the thread of the ball-head

screws will no longer stick in the transverse links).

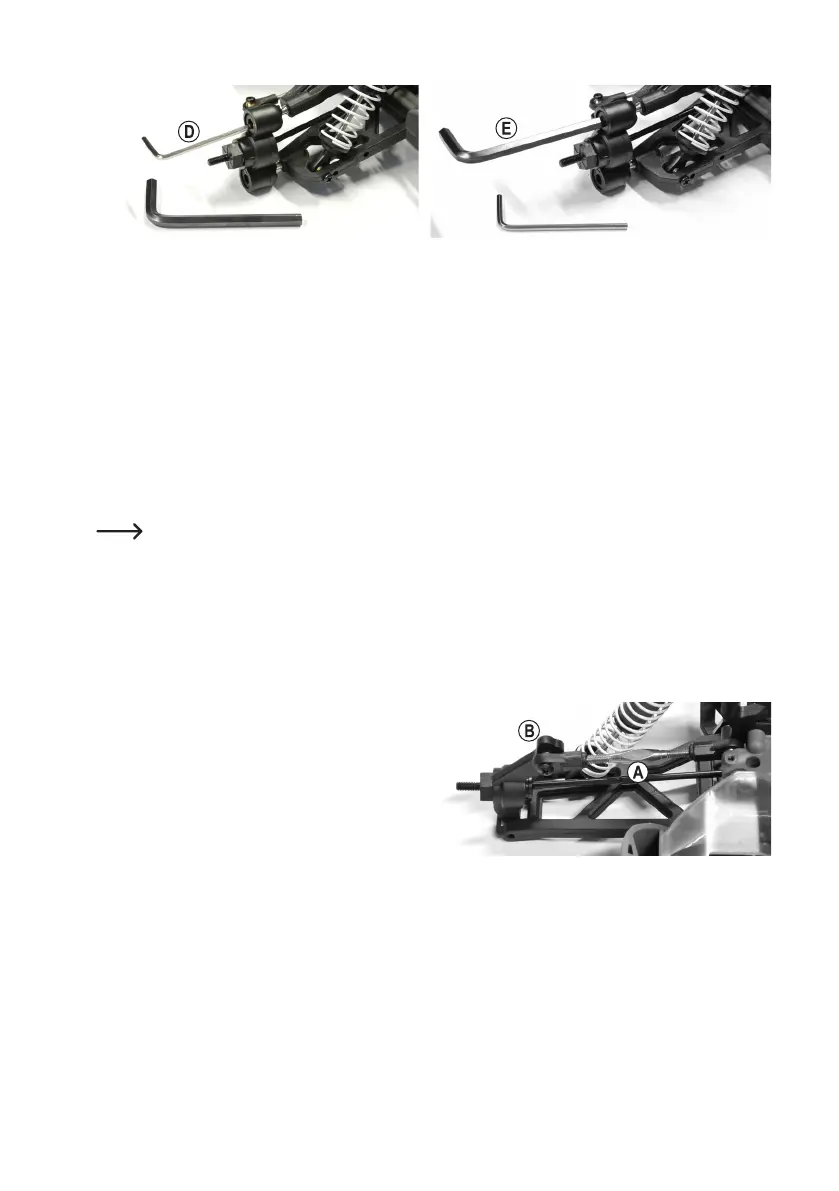

Setting Rear Axle Camber:

For setting the camber, turn the screw (A) of the upper

transverse link.

Because this screw has a left and right hand thread at

either end, the transverse link does not need to be dis-

mantled for the camber to be adjusted.

Furthermore, the rear axle stub (B) has several different

suspension points for the upper transverse link.

Ifthetransverselinkwasattachedinadifferentlocation,thiswouldchangethecamberwhenthewheeldeectsand

extends.

The manufacturer already selected the best setting for the vehicle. Therefore, you should not change the attachment

point (B).

Loading...

Loading...