Rev 0.2 31 | P a g e

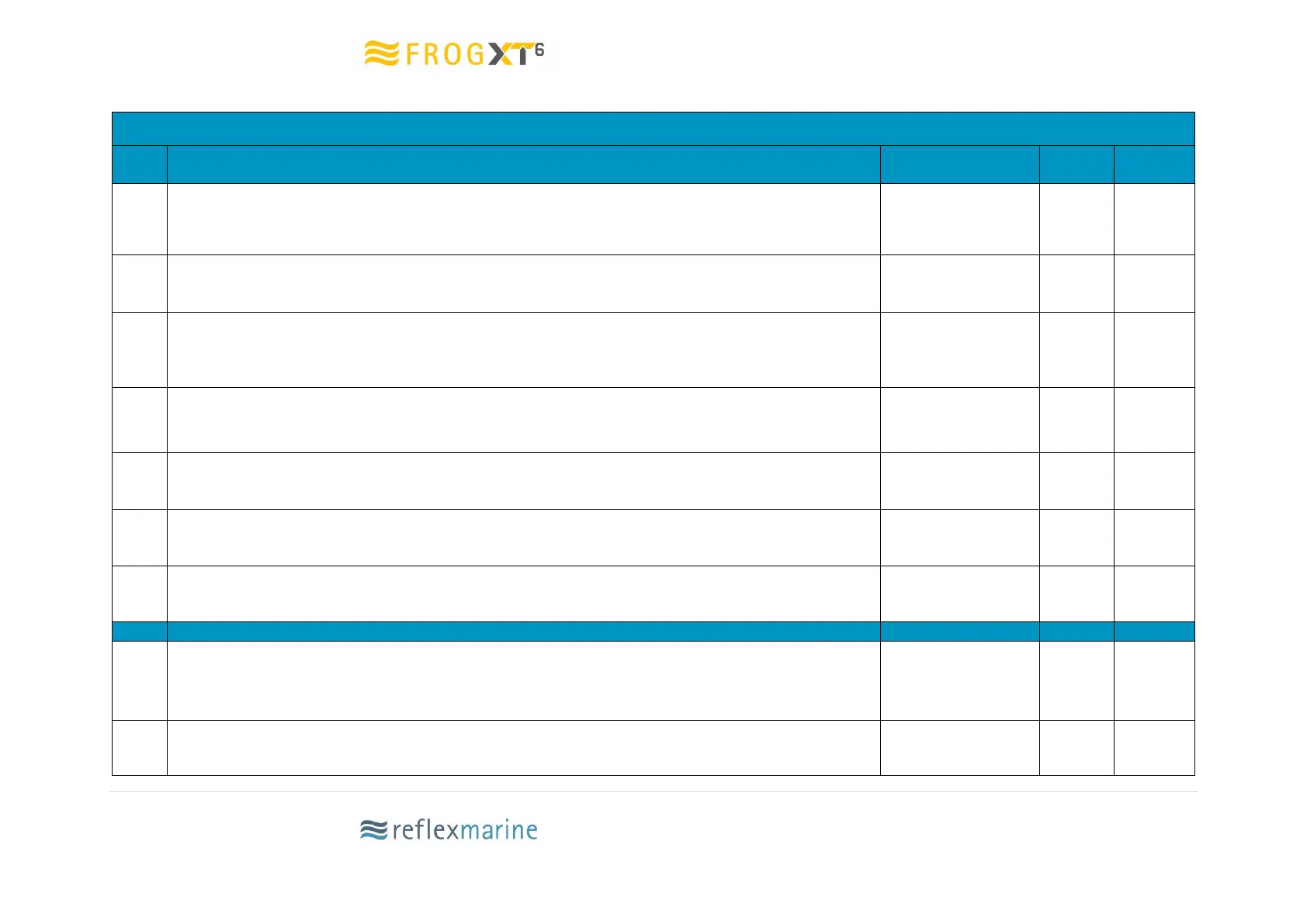

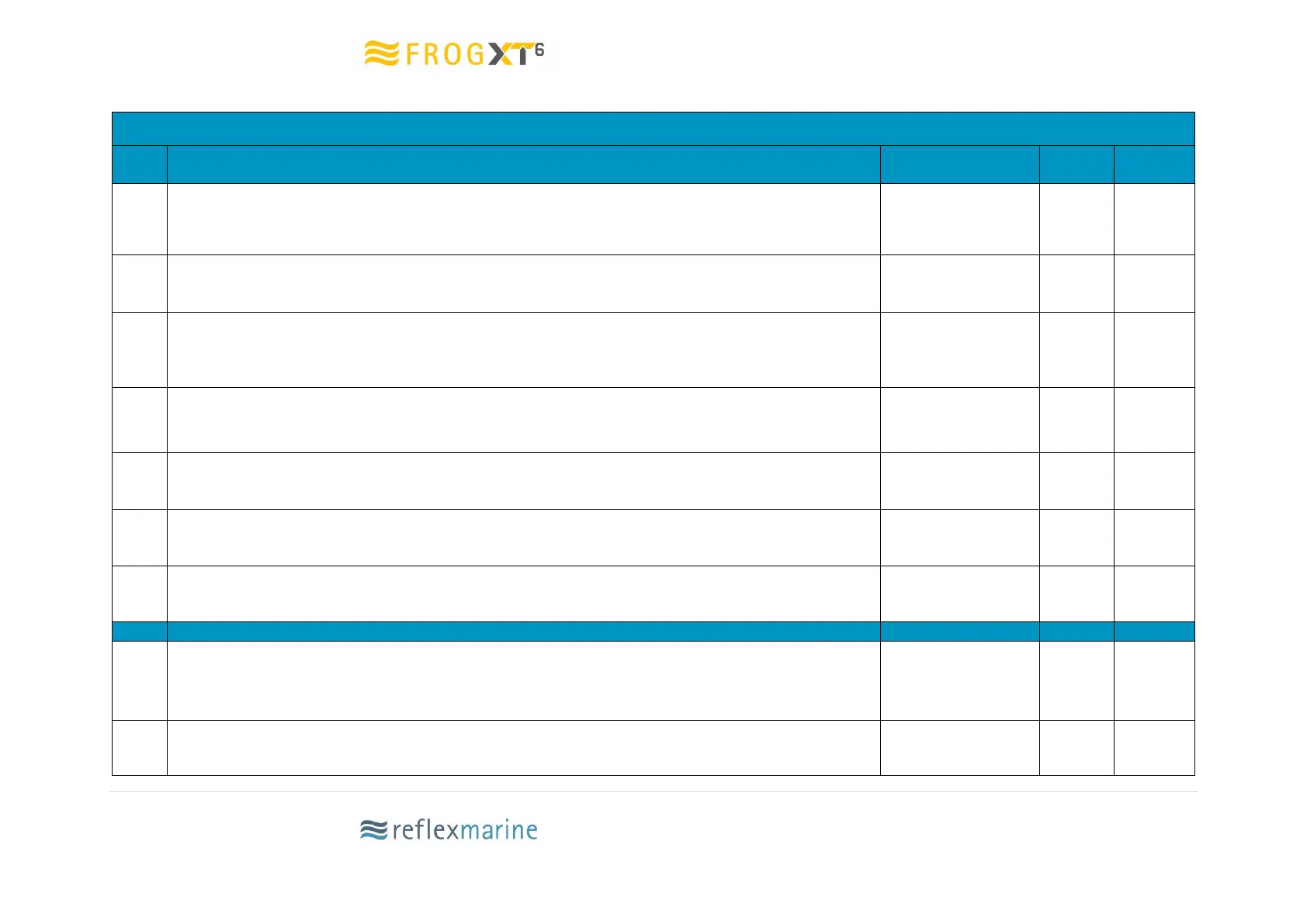

Frog XT6 Examination Checklist continued…

Comment / Serial

No./ Colour Code

Visually inspect the seat harness attachment points and the harness webbing for any signs of wear,

fraying or damage. Check that attachment points are secure.

Sit in each seat and check fastening and unfastening of each harness, to ensure correct operation.

Check the date of the last examination/ inspection to ensure the unit will remain in compliance with

requirements for at least 6 months. Update data plate to show visual examination has been done.

Stickers - Check that all of the stickers on the unit are in good condition and that none are missing

or damaged. The sticker location drawing can be found in the drawing pack.

Stretcher Fittings – Visually inspect the stretcher fittings to ensure that they are all present and in

good condition.

Load Test - On critical parts replacement, a load test must be conducted. This is to be done by an

independent test house company, nationally recognised and in accordance with ILO 152.

Post Load Test Visual Inspection – If a load test is done, conduct and report a post load test

visual inspection.

Storage of FROG - Check the storage cover is in good condition and not showing any signs of UV

or wind degradation.

Storage off the ground , use of spacer chocks whilst not in use

Replacement Parts Stock - Check condition of all associated replacement parts and accessories.

Lifting assemblies should be stored in an appropriate dry place without high visibility cover fitted.

Loading...

Loading...