Vacuum spray degassing — 28.08.2019 - Rev. B

English — 15

6.3.3 Degassing line to the system

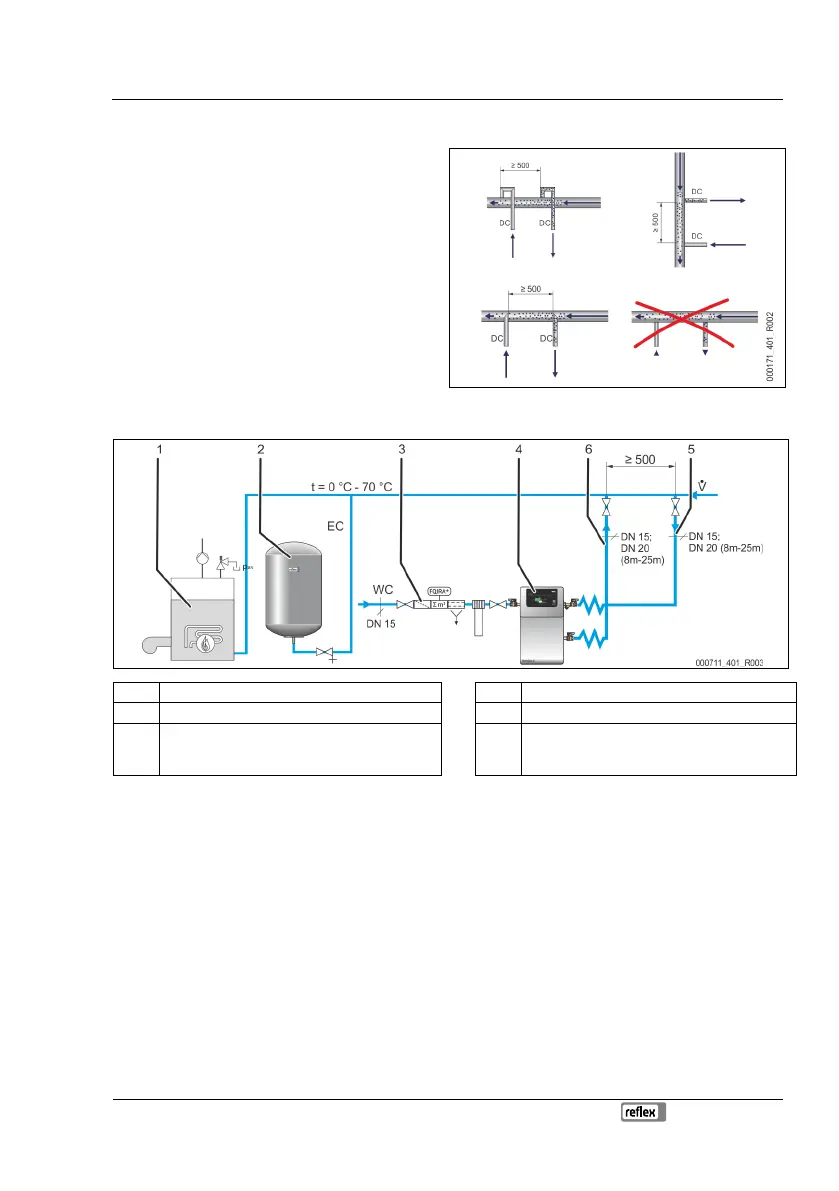

Installation detail of the "DC" degassing line

Install the "DC" degassing lines as follows:

Prevent an overload of the "ST" dirt trap in the device

caused by coarse dirt.

Install the gas-rich degassing pipe “DC” upstream of the

gas-poor degassing pipe (when viewed in the system

flow direction).

Preferably install on the return side of the facility

system.

– The water temperature must be in the range of 0

°C – 70 °C to ensure sufficient degassing

capacity.

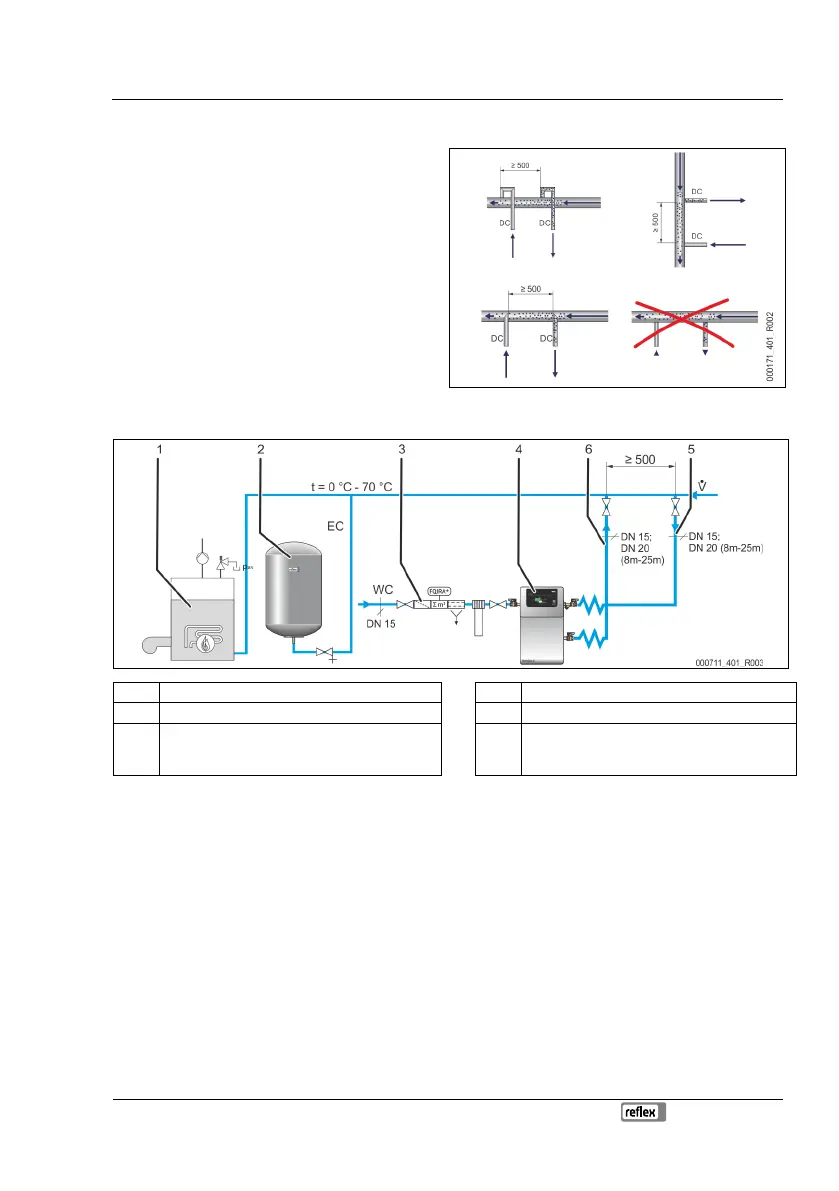

Device installation in a heating system – Pressure maintenance with bladder "MAG" expansion vessel

1 Heating system 4 Device

2 Bladder expansion vessel 5 "DC" degassing line (gas-rich water)

3 For optional equipment and accessories, see

chapter 4.5 "Optional equipment and accessories"

on page 10

6 "DC" degassing line (degassed water)

Proceed as follows:

• Connect the "DC" degassing lines in the "V" main volume flow of the facility system.

• The device requires two "DC" degassing lines to the facility system.

– One degassing line for the gas-rich water from the facility system

– One degassing line for the degassed water back to the facility system.

• Fit the degassing lines near the "EC" expansion line.

– This ensures stable pressure conditions.

• Install the device near the "MAG" expansion vessel.

– This ensures pressure monitoring of the expansion vessel.

– Set the "Magcontrol" operating mode at the device controller.

Ensure the integration with the "V“ main flow volume. in particular in switching variants with hydraulic

switching points and return admixtures.

– For switching and make-up variants, see chapter 6.4 "Switching and make-up variants" on page 16 .

Loading...

Loading...