Variomat Touch — 09.2020 - Rev. A

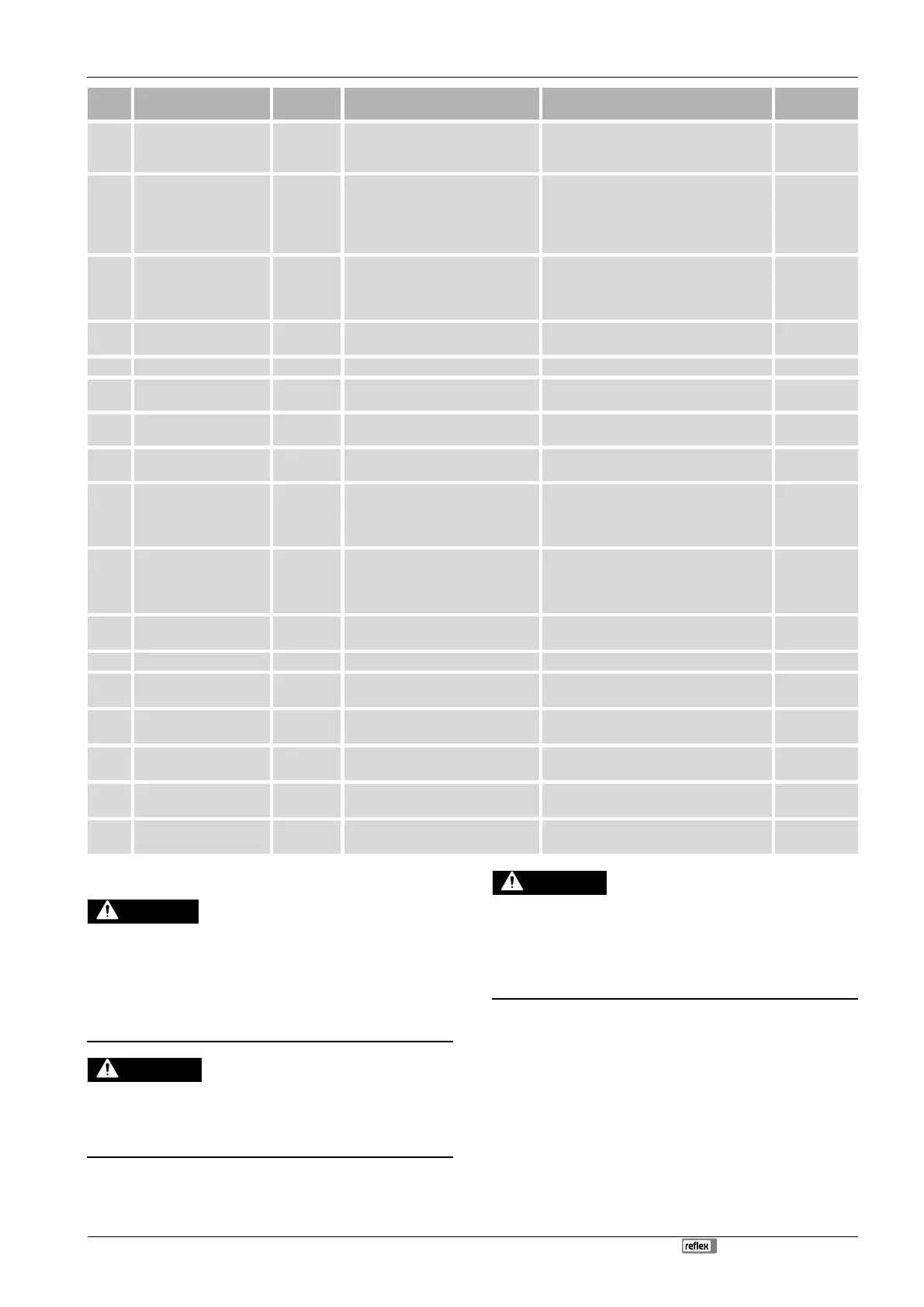

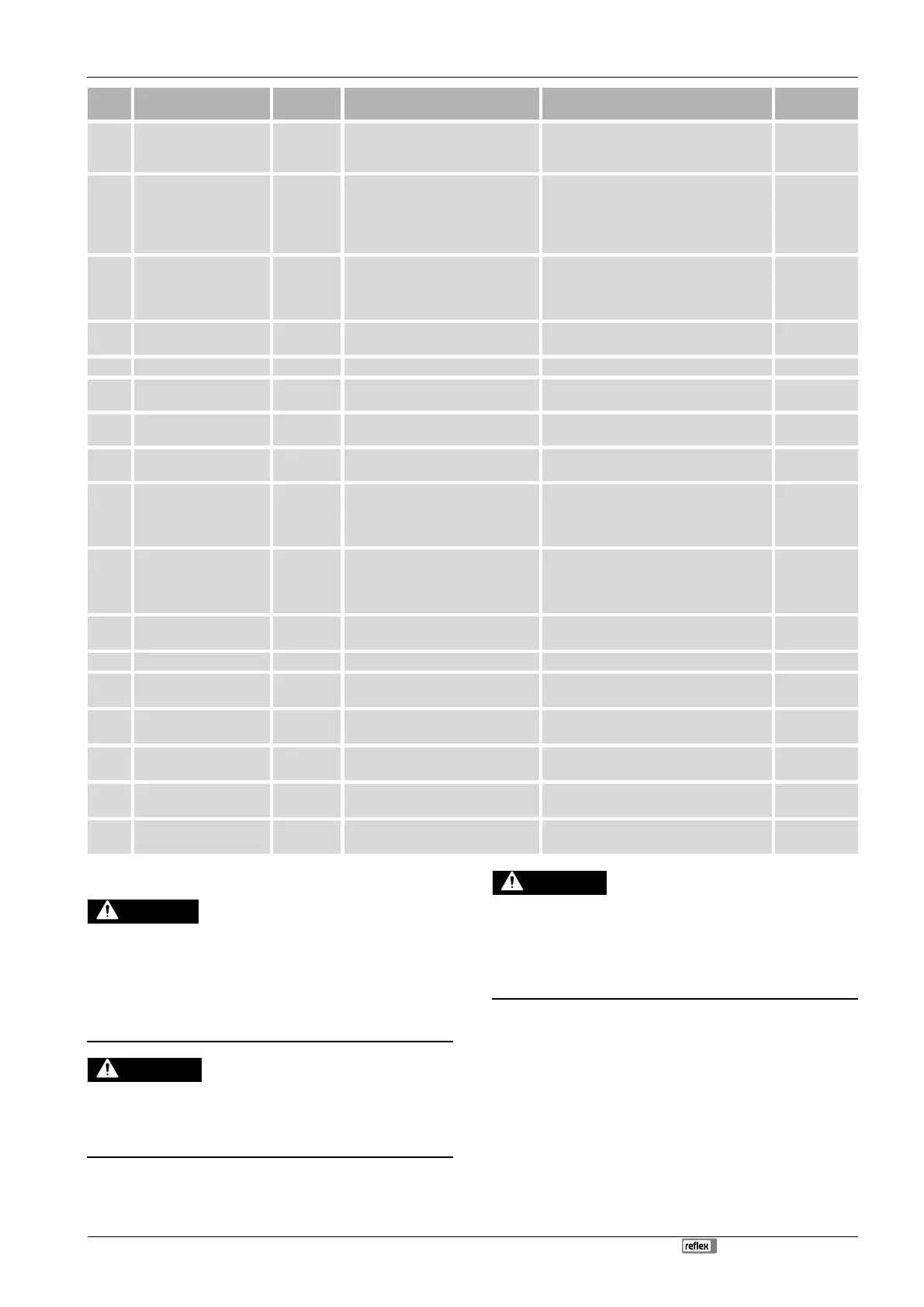

Controller receives incorrect signal.

• Check functioning of the load cell.

• Check the cable for damage.

• Connect the plug.

• Set value exceeded.

• Pressure relief pipe not functioning.

• Dirt trap clogged.

• Check set value in the Customer or Service

menu.

• Check functioning of the pressure relief

pipe.

• Clean the dirt trap.

"With water meter" must be activated in

the Customer menu.

• Set value exceeded.

• Severe water loss in the system.

• Check set value in the Customer or Service

menu.

• Check water loss in the system and repair,

if necessary.

Contact water meter measures without

make-up request.

Check the make-up valve for leaks.

Device is in Stop mode for more than 4

hours.

Set the controller to Automatic mode.

Reset the "Make-up quantity" meter in the

Customer menu.

Perform maintenance and reset the maintenance

counter upon completion.

• Set value for soft water capacity

exceeded.

• Time interval for replacement of the

softening cartridge exceeded.

Replace the softening cartridges.

• I/O module defective.

• Connection between option card

and controller faulty.

• Option card defective.

Inform Reflex Customer Service.

• EEPROM defective.

• Internal calculation error.

Inform Reflex Customer Service.

Supply voltage not achieved.

Adjustment parameter

faulty

EEPROM parameter memory defective.

Inform Reflex Customer Service.

Communication

Main board faulty

• Connecting cable defective.

• Main board defective.

Inform Reflex Customer Service.

Digital input voltage

faulty

Short-circuit of input voltage.

Check the wiring at the digital inputs (water

meter, for example).

Analogue input voltage

faulty

Short-circuit of input voltage.

Check the wiring at the analogue inputs

(pressure/level).

Input voltage

Ball valve missing

Short-circuit of input voltage.

Check wiring of the ball valve.

Risk of serious injury or death due to electric shock.

If live parts are touched, there is risk of life-threatening injuries.

• Ensure that the system is voltage-free before installing the device.

• Ensure that the system is secured and cannot be reactivated by other

persons.

• Ensure that installation work for the electric connection of the device is

carried out by an electrician, and in compliance with electrical

engineering regulations.

Risk of burns

Escaping hot medium can cause burns.

• Maintain a sufficient distance from the escaping medium.

• Wear suitable personal protective equipment (safety gloves and

goggles).

Risk of injury due to pressurised liquid

If installation, removal or maintenance work is not carried out correctly, there

is a risk of burns and other injuries at the connection points, if pressurised

hot water or hot steam suddenly escapes.

• Ensure proper installation, removal or maintenance work.

• Ensure that the system is de-pressurised before performing installation,

removal or maintenance work at the connection points.

The device is to be maintained annually.

– The maintenance intervals depend on the operating conditions and the

degassing times.

The annual maintenance is displayed upon expiry of the set operating time. Use

"OK" to acknowledge the "Maintenance recommended" message. Reset the

maintenance counter in the Customer menu.

Note!

The maintenance intervals of the secondary vessels can be extended up

to 5 years, if no abnormalities have been detected during operation.

Loading...

Loading...