Cosmetic Care & Maintenance

7-21

Bilge Pump

The bilge pump is usually installed in the engine compartment just

below the engine front. Check for foreign materials stuck in the strainer

area or discharge hose.

Check all clamps and electrical connections for tightness. A quick check

of the bilge pump automatic fl oat switch is afforded by lifting up on

the fl oat and listening for the pump operating. Look around the fl oat

area for foreign debris and remove as necessary.

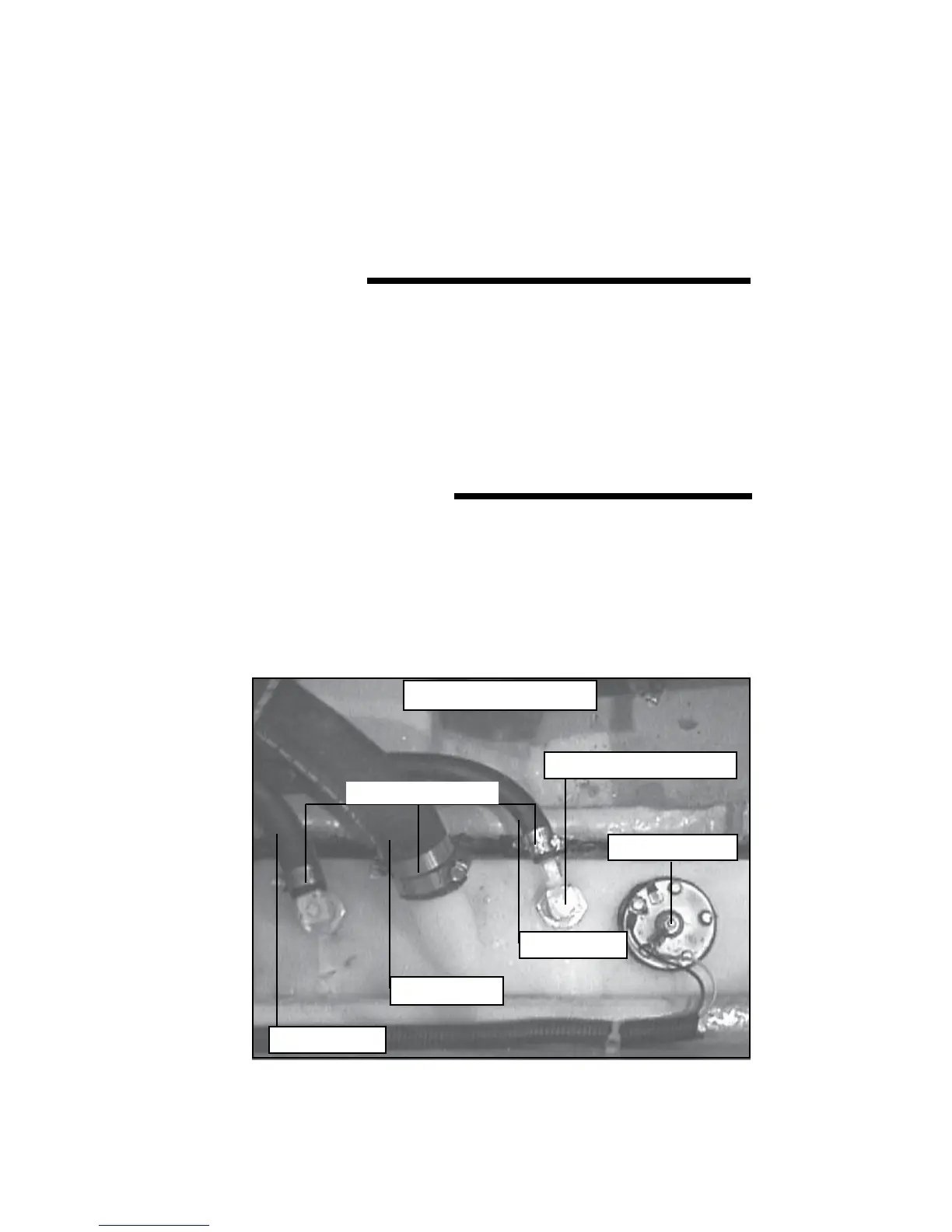

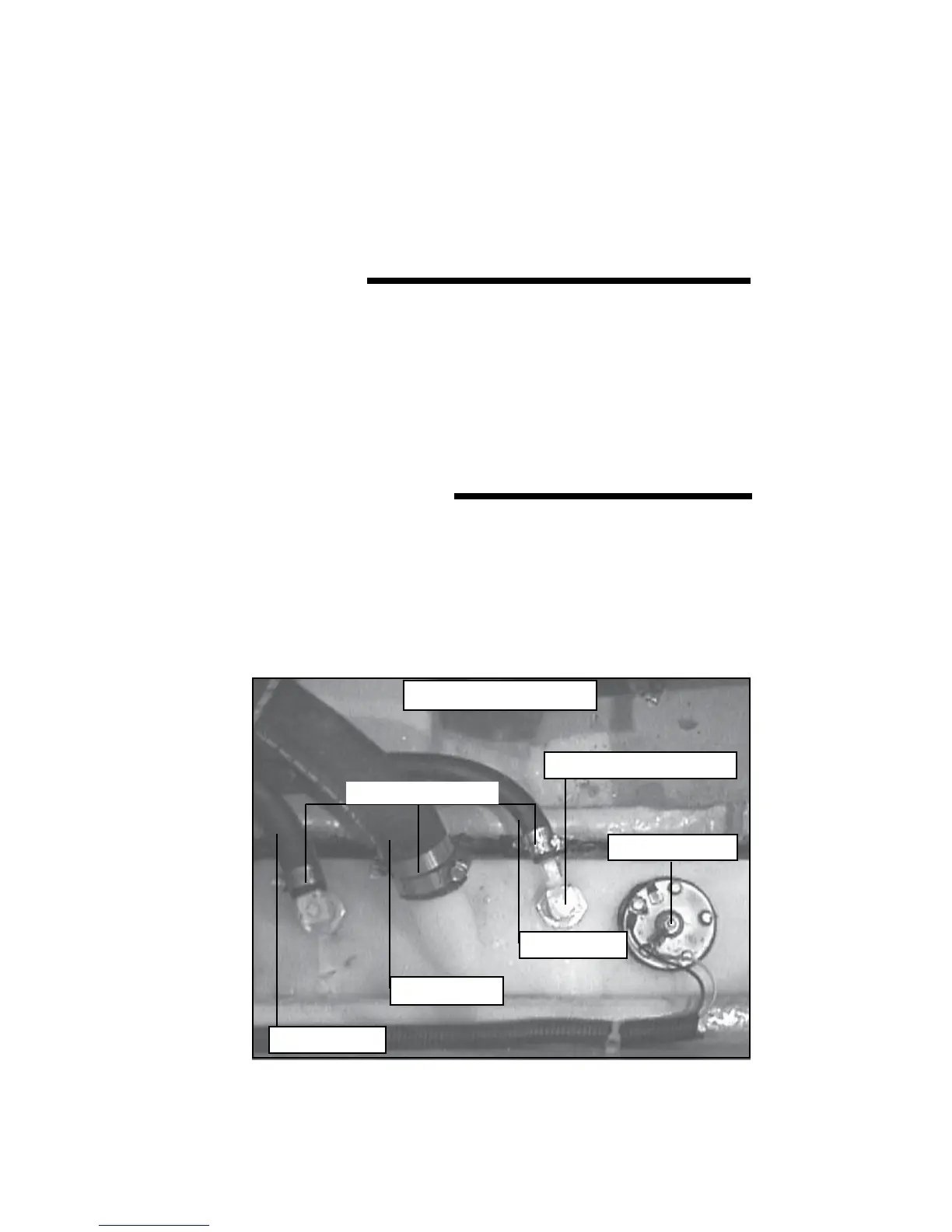

Fuel Tank & Fittings

Periodically inspect the fuel tank components for loose clamps at

the vent, fi ll and feed locations. Examine each hose for signs of

deterioration and leakage. Check the fuel sender for loose bolts, nuts,

and leaks at all areas of contact. Also, inspect the fuel tank for signs

of leakage or abrasion. Tighten all components as needed.

HOSE CLAMPS

FUEL FEED

FUEL SENDER

ANTI-SIPHON VALVE

TYPICAL FUEL TANK

FUEL VENT

FUEL FILL

Loading...

Loading...