Cosmetic Care & Maintenance

7-11

MAINTENANCE

Out-of-balance or nicked props will effect performance or cause

vibration. Damaged props should be replaced, but those that are

chipped or bent can usually be reconditioned by a marine dealer or a

propeller repair facility. When cruising, consider carrying a spare set

of props onboard because many marinas do not carry a full inventory

of replacement propellers. Refer to the manufacturer’s engine manual

for appropriate stern drive and inboard propeller replacement.

Be sure to make a note of the propeller diameter and pitch while the

vessel is in dry dock. They are pressed into the prop for easy reading.

In an emergency an aluminum propeller blade can be straightened by

laying the propeller blade on a 2 x 4 and hammering the bent portion

of the blade until straight. This procedure will assist the operator in

reaching port so he can have the propeller repitched.

It is advantageous to carry the needed tools to change propeller(s).

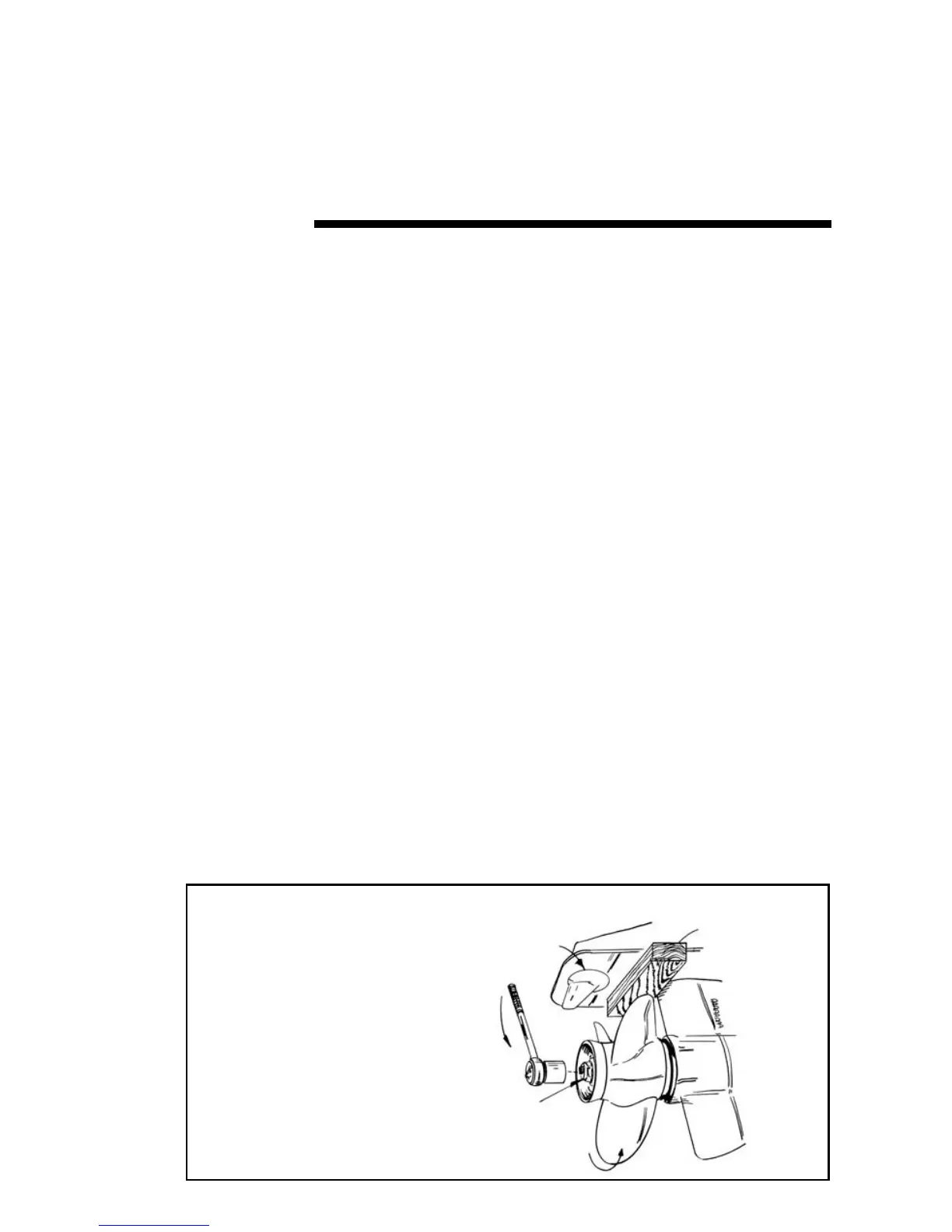

Use the following procedure to remove single stern drive propellers.

This method provides a safety margin from sharp propeller blades

especially those with stainless steel propellers. The 2 x 4 when laid

across the ventilation plate allows safe removal of propeller. With

MerCruiser alpha drives make sure the washer tabs are bent up before

trying to remove the prop nut. With Volvo SX drives, remove the

propshaft cotter key and splined washer first to access the nut.

Propellers

PROPELLER SHAFT NUT

ZINC ANODE

2X4 WOOD

COUNTERCLOCKWISE

TO LOOSEN

CLOCKWISE

TO TIGHTEN

TYPICAL PROPELLER CHANGING-

MERCRUISER ALPHA

Cosmetic Care & Maintenance

7-11

MAINTENANCE

Out-of-balance or nicked props will effect performance or cause

vibration. Damaged props should be replaced, but those that are

chipped or bent can usually be reconditioned by a marine dealer or a

propeller repair facility. When cruising, consider carrying a spare set

of props onboard because many marinas do not carry a full inventory

of replacement propellers. Refer to the manufacturer’s engine manual

for appropriate stern drive and inboard propeller replacement.

Be sure to make a note of the propeller diameter and pitch while the

vessel is in dry dock. They are pressed into the prop for easy reading.

In an emergency an aluminum propeller blade can be straightened by

laying the propeller blade on a 2 x 4 and hammering the bent portion

of the blade until straight. This procedure will assist the operator in

reaching port so he can have the propeller repitched.

It is advantageous to carry the needed tools to change propeller(s).

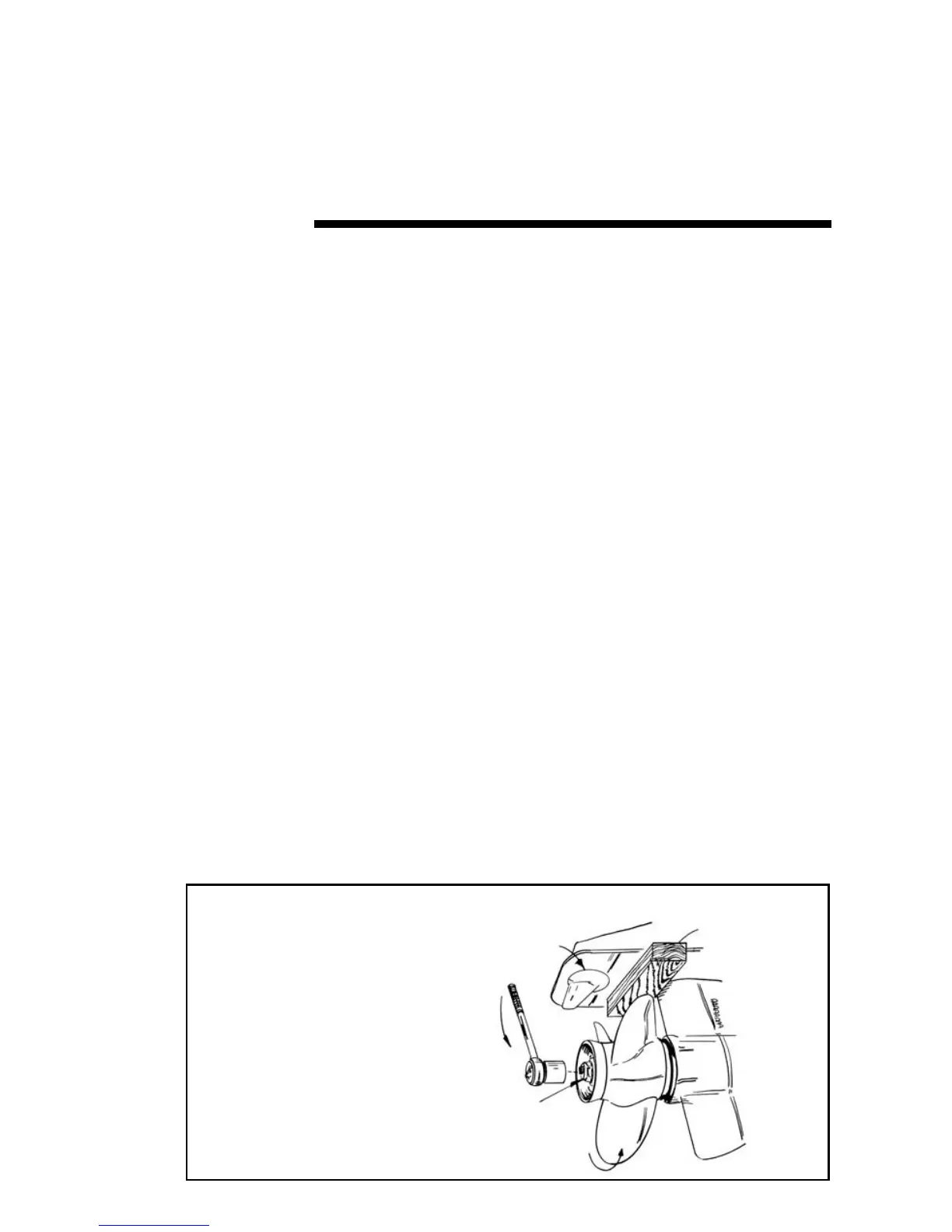

Use the following procedure to remove single stern drive propellers.

This method provides a safety margin from sharp propeller blades

especially those with stainless steel propellers. The 2 x 4 when laid

across the ventilation plate allows safe removal of propeller. With

MerCruiser alpha drives make sure the washer tabs are bent up before

trying to remove the prop nut. With Volvo SX drives, remove the

propshaft cotter key and splined washer first to access the nut.

Propellers

PROPELLER SHAFT NUT

ZINC ANODE

2X4 WOOD

COUNTERCLOCKWISE

TO LOOSEN

CLOCKWISE

TO TIGHTEN

TYPICAL PROPELLER CHANGING-

MERCRUISER ALPHA

Loading...

Loading...