26 | Regency

®

CLASSIC C34-10 Direct Vent Freestanding Gas Stove

|

26

installation

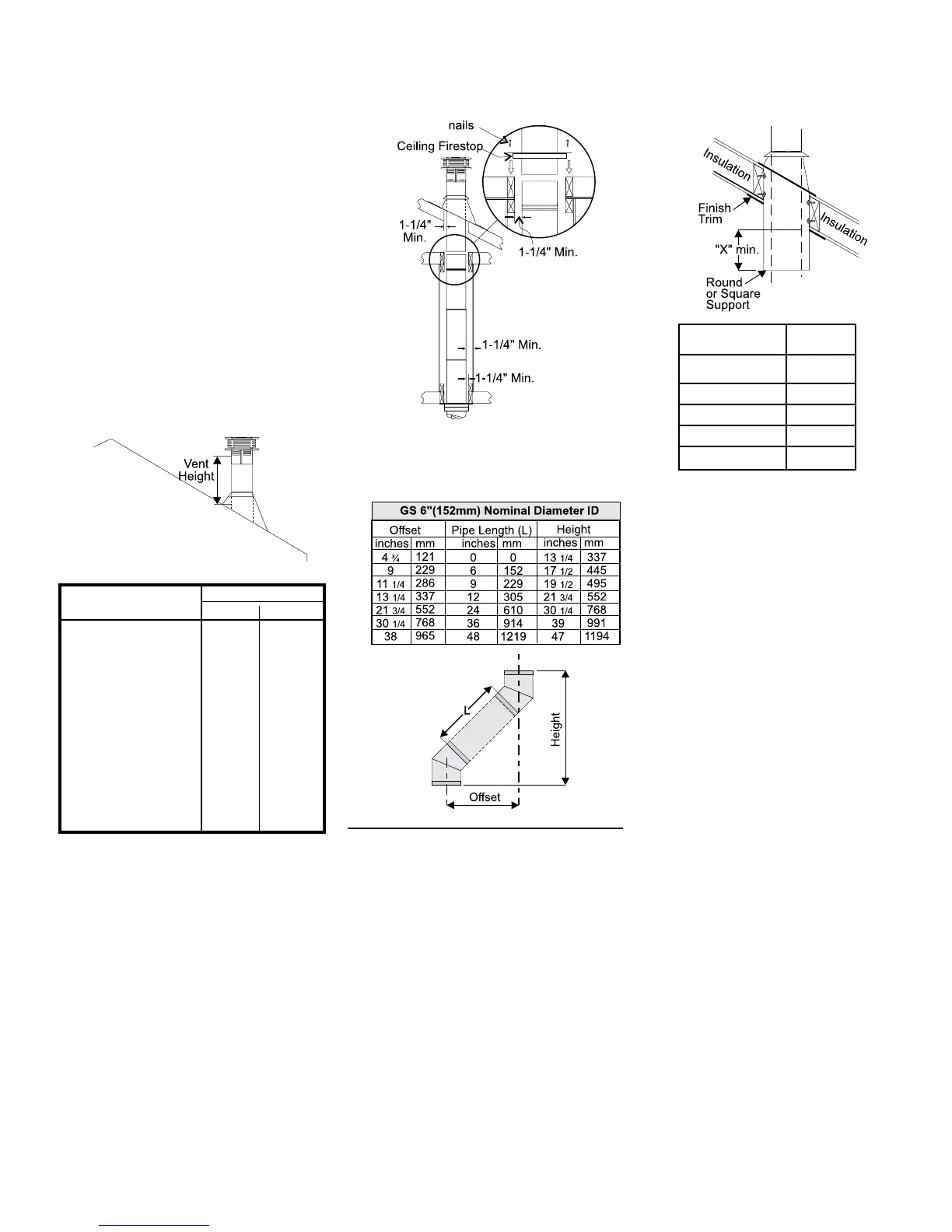

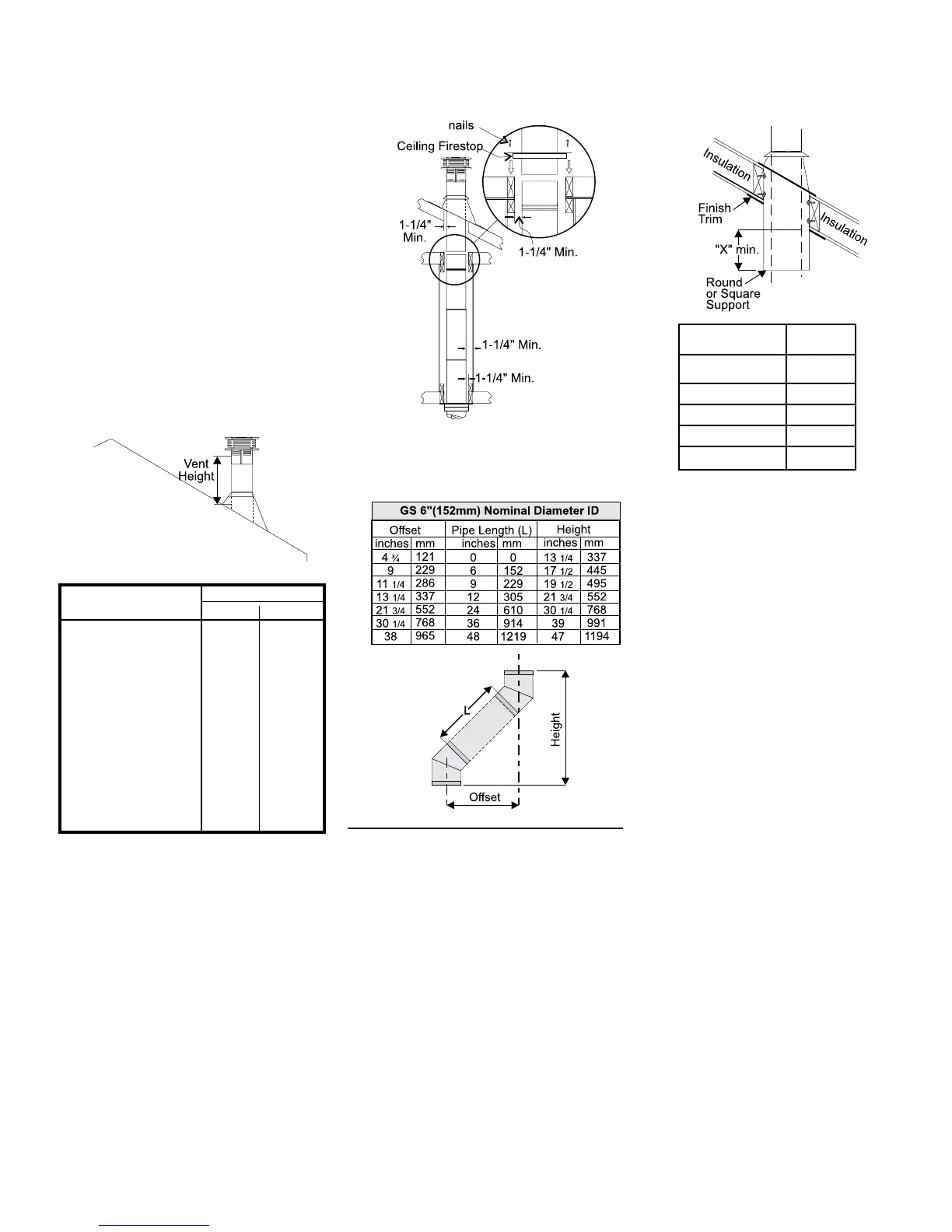

CATHEDRAL CEILINGS

Round Support (RDS) & Square

Support (SQS)

If your home has a cathedral ceiling (no attic space

between the ceiling and the roof), install the chimney

and support as follows.

1. Situate the chimney in a convenient location as

near as possible to the appliance outlet. Cut

and frame a hole in the roof for the support. The

sides of this hole must be vertical with 1-1/4"

clearance.

2. Place the support in the opening. Lower it to the

correct height as determined by the table and

diagram below.

Using a level, make sure the support is vertical.

If the support extends above the roof, cut

it ush with the top of the roof. Nail the

support to the frame opening using (8. 3"

spiral nails or #8 x 1-1/2" screws.

Note: If you are using a 6" square support

you may nd it difcult to screw it

in place because it is fairly small

inside.

Simpson Dura-Vent has provided angle

brackets with this support which can be

screwed to the outside of the support

box and nailed to surrounding framing as

required. Use a minimum of four #8 x 1/2"

screws per bracket. In some cases these

brackets may need to be trimmed (e.g.:

to t under a ashing). Place the Finish

Collar around the support and fasten it to

the ceiling using the screws provided.

3. Use appropriate roof ashing. Place the

ashing under the upper shingles and on top

of the lower shingles approximately half of

the ashing should be under the shingles.

4. Assemble the desired lengths of Black Pipe

and Elbows necessary to reach from the

appliance adaptor up through the support

box and ashing to proper height as per

Diagram 12, local codes or "Exterior Vent

Terminal Locations" section. Ensure that

all pipe and elbow connections are in their

fully twist lock position.

5. Ensure vent is vertical and secure ashing to

the roof with roong nails. Slide the storm

collar over the pipe section and seal with a

mastic.

6. Twist lock the vent cap on to the last section.

Offset Chart

Diagram 12

Diagram 13

Roof Pitch Minimum Vent Height

Feet Meters

at to 7/12 2 0.61

over 7/12 to 8/12 2 0.61

over 8/12 to 9/12 2 0.61

over 9/12 to 10/12 2.5 0.76

over 10/12 to 11/12 3.25 0.99

over 11/12 to 12/12 4 1.22

over 12/12 to 14/12 5 1.52

over 14/12 to 16/12 6 1.83

over 16/12 to 18/12 7 2.13

over 18/12 to 20/12 7.5 2.29

over 20/12 to 21/12 8 2.44

Galvanized pipe and elbows may be utilized

in the attic as well as above the rooine. The

galvanized nish is desirable above the rooine

due to its higher corrosion resistance.

Continue to add pipe sections through the

ashing until the height of the vent cap meets

the minimum height requirements specied

in diagram 12 or local codes. Note that for

steep roof pitches, the vertical height must be

increased. A poor draft, or down drafting can

result from high wind conditions near big trees

or adjoining roof lines, in these cases, increasing

the vent height may solve the problem.

7. Ensure vent is vertical and secure the base of

the ashing to the roof with roong rails, slide

storm collar over the pipe section and seal with

a mastic.

8. Install the vertical termination cap by twist lock-

ing it.

Notes:

a) For multistorey vertical installations, a Ceil-

ing Fire stop is required at the second oor,

and any subsequent oor. See diagram 13.

The opening should be framed to 10 " x 10"

inside dimensions, in the same manner as

shown in diagram 10.

b) Any occupied areas above the rst oor,

including closets and storage spaces,

through which the vertical vent passes,

must be enclosed.

Slope "X"

0/12 - 2/12 4"

2/12 - 7/12 5-1/2"

7/12 - 12/12 6-3/4"

12/12 - 24/12 7-1/2"

24/12+ 12-1/2"

Loading...

Loading...