- 11 -

EN

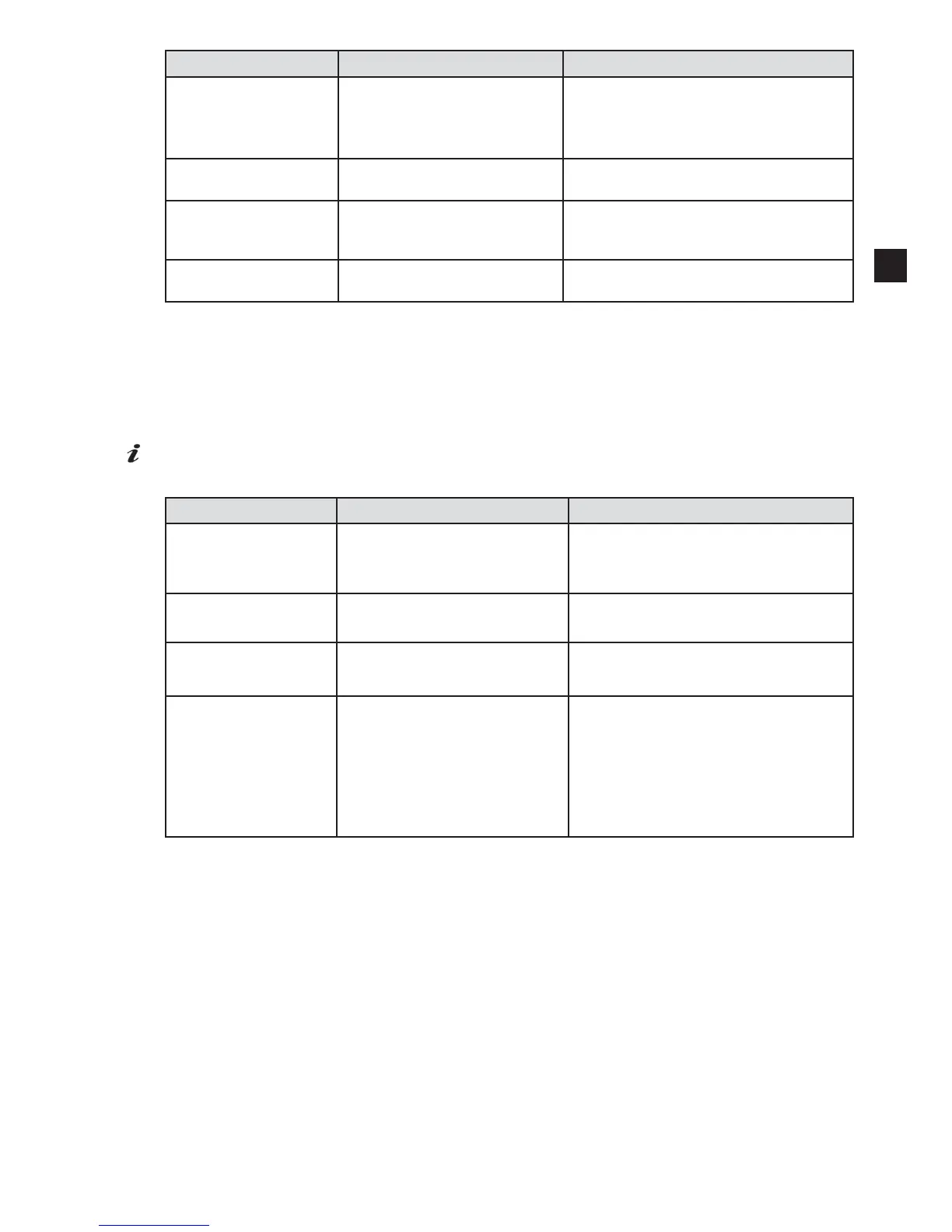

Error Cause Solution

Vacuum release / venting,

too slow.

6XFWLRQ¿OWHUV\VWHPSOXJJHG +DYH¿OWHUFOHDQHGRUFKDQJHG6HF

Silencer plugged. Replace the silencer. (Sec. 7.6).

&RQQHFW¿OWHUSUHVVXUHUHJXODWRULQVHULHV

Solenoid valve fault. Have the device repaired.

No vacuum being gene-

rated.

Bowl detection pin sticking. Clean area around pin.

Have the device repaired.

Permanent venting noise.

Solenoid valve fault. Have the device repaired.

Bowl detection pin sticking. Clean area around pin.

Have the device repaired.

Fluttering noise from the

silencer.

Working pressure too low. Check dynamic operating pressure

(see technical data, Sec. 9).

8.3 Error codes

7KHIROORZLQJLQGLFDWLRQVZLOOEHJLYHQLIWKHHOHFWURQLFV\VWHPGHWHFWVDQHUURU

A warning signal will sound

7KHGLVSOD\ZLOOÀDVKDOWHUQDWHO\Ä(UU³DQGDQHUURUFRGH

(QGRIHUURUGLVSOD\

Press control button (except for Err 3, 5 and 6)

(UUDQG6ZLWFKGHYLFHRIIIROORZDGYLFHLQVHFWLRQ³SRZHUIDLOXUH´

:LWK(UULWPD\QRORQJHUEHSRVVLEOHWRUHPRYHWKHPL[LQJERZO

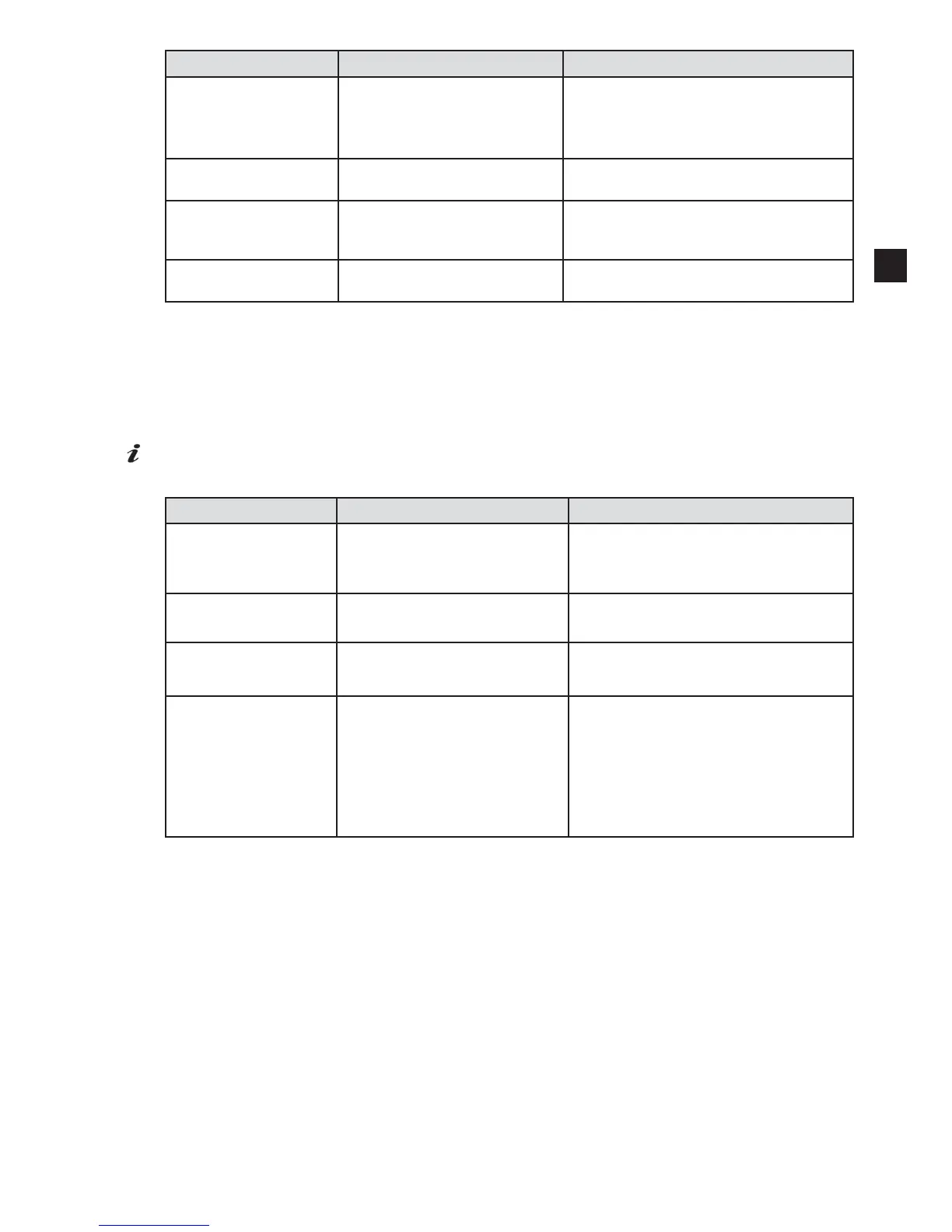

With an error code as shown in the following table, please proceed as advised.

Error code Cause Solution

Err. 2

Minimum vacuum level not yet

reached.

Vacuum level has dropped below

500 mbar.

Ventilate bowl and remove (see section

5.4.1, points no. 2 and 3)

,IWKHHUURUUHFXUV

Have the device repaired.

Err. 3

The vacuum is built-up too quickly

due to the fact that the suction

system is blocked.

+DYH¿OWHUFOHDQHGRUFKDQJHG6HF

Err. 4

Motor fault. Ventilate bowl and remove (see Sec. 5.4.1,

points no. 2 and 3)

Have the device repaired.

Err. 10

Too much material.

Mixing time too long, the material

has already begun to set

Ventilate bowl and remove (see section

5.4.1, points no. 2 and 3)

2QO\¿OOWKHERZOWRWKHPD[LPXP¿OOOHYHO

This limit is valid for powders and liquids

measured before mixing.

Ventilate bowl and remove (see section

5.4.1, points no. 2 and 3)

Select shorter mixing times.

)RUDOORWKHUHUURUFRGHV

Note error code

Have the device repaired.

Quote the error code to the repair service

EN

Loading...

Loading...