Owners Manual • Falk Quadrive Shaft Mounted Drives Model A

(Page 4 of 52) Sizes 5107-5315

378-200 (PN-2128394) Rexnord

January 2019 3001 W. Canal St., Milwaukee, WI 53208-4200 USA

Supersedes 04-17 Telephone: 414-342-3131 Fax: 414-937-4359 www.rexnord.com

Section I

DRIVE INSTALLATION

OUTFITTING

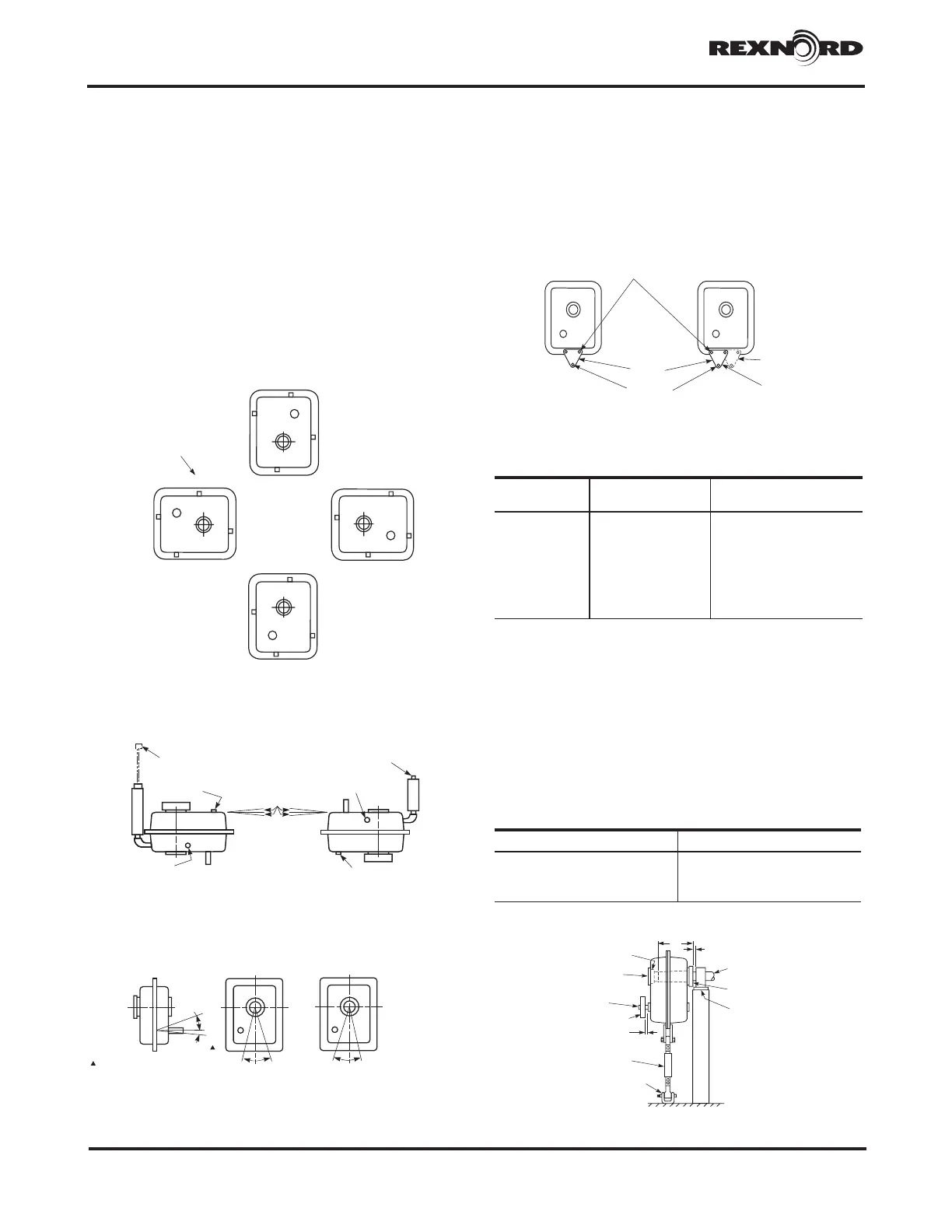

1. JR, JF, & JSC — Find the desired mounting position

in Figure 1 and install air vent and magnetic drain plug

(packaged separately with basic drive). Also note and/

or mark the oil level plug location OR in the case of a

vertical mounting, refer to Appendix E for installation

of vertical stand pipe. If the mounting angle exceeds

the limitations shown in Figure 1, refer to Appendix F

to determine modifications necessary within the limits

illustrated therein. DO NOT fill drive with lubricant at

this time. Oil plugs are located on input housing half.

2. JR — Remove anchor brackets, housing flange fasteners

and rod end fasteners from tie rod kit and assemble

to drive as illustrated in Figure 2. Refer to Table 1 for

tightening torque (original fasteners may be discarded).

FILL

DRAIN

OIL LEVEL

STANDPIPE &

VENTED DIPSTICK

FILL VENT &

STANDPIPE

INPUT SHAFT DOWN

INPUT SHAFT UP

DRAIN

± 1° MAX

12 O’ CLOCK

D

L

F

F

L

D

3O’CLOCK

F

L

D

6O’CLOCK

F

L

D

9O’CLOCK

SIZES 5203 THRU 5315

5:1 RATIO ONLY: RELOCATE

AIRVENT ON OUTPUT SIDE

FOR 9 O’CLOCK MOUNTING

REPOSITION PLUGS TO

SUIT REQ’D MOUNTING

D = DRAIN

F = Fill & Vent

L = OIL LEVEL

(HIGHEST INPUT

SIDE PLUG)

10

MAX

°

5°

MAX

30 UP

(20° FOR

5315)

°

5DOWN°

INCLINE ROTATION

5°

MAX

10°

MAX

(5107&5115) (5203 THRU 5315)

0° Incline down on drives

with backstop in 9 or 12

o’clock mounting position.

HORIZONTAL DRIVESFigure 1

VERTICAL DRIVES

ANGULAR LIMITS FOR HORIZONTAL MOUNTING

(ALL CLOCK POSITIONS)

5107&5115 5203 THRU 5315

HOUSING FLANGE

FASTENERS

ANCHOR

BRACKET

TORQUE ARM

FASTENER

ALTERNATE

LOCATION

PREFERRED

LOCATION

Figure 2

TABLE 1 — Housing Flange Fastener Size

and Tightening Torque

(Non-Lubricated Fasteners)

DRIVE SIZE Fastener Size

Tightening Torque lb-ft

(Nm)

5107 .312-18 19 (26)

5115 .312-18 19 (26)

5203 .375-16 28 (37)

5207 .500-13 69 (94)

5215 .500-13 69 (94)

5307 .500-13 69 (94)

5315 .500-13 69 (94)

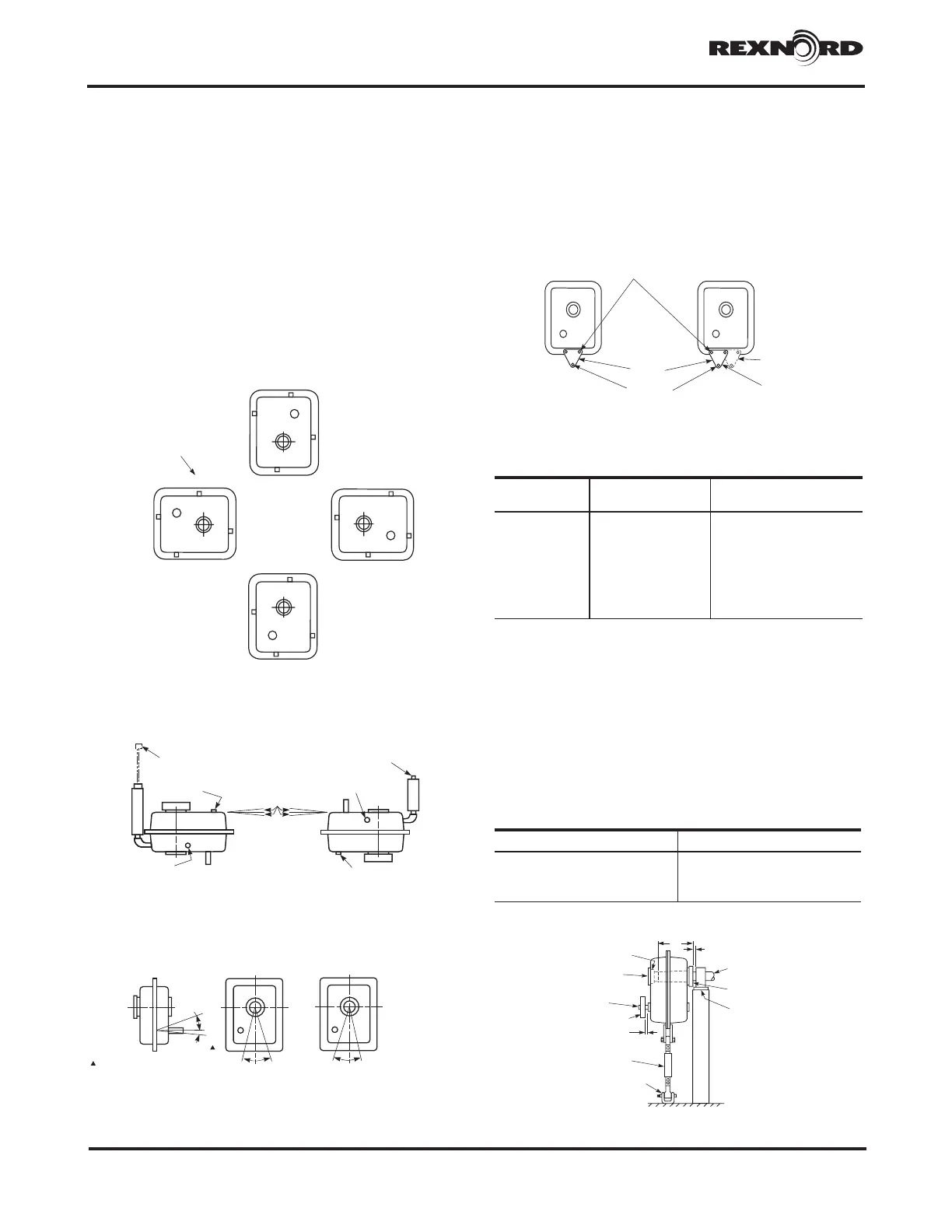

3. JR — The tapered bore hollow shaft is designed for use

with a TA Taper bushing for mounting on a driven shaft with

a straight outside diameter. Shaft tolerances for the driven

shaft are given in Table 1A. The minimum and maximum

driven shaft engagements, dimension “N” in Figure 3, are

shown in Table 2. The minimum engagement is necessary

for full bushing engagement; the maximum engagement is

only required if a thrust plate will be employed to remove the

drive from the driven shaft (see Appendix C for preferred

removal method).

TABLE 1A — Driven Shaft Tolerances

Shaft Diameter – Inches Maximum Under-size – Inches

Up to 1.500 .004

1.500 - 2.500 incl. .005

2.500 - 4.000 incl. .006

c Millimeters = h10 tolerance.

N

THRUST

PLATE

HOLLOW

SHAFT

COVER

HIGH-SPEED

SHAFT

SHEAVE

MINIMUM SPACE REQUIRED

FOR V-BELT CLEARANCE

TORQUE

ARM

CLEVIS

BRACKET

MINIMUM SPACE REQUIRED

DRIVEN

SHAFT

BUSHING

NUT

BEARING

SUPPORT

Figure 3

Loading...

Loading...