Hardware Installation and Reference Guide Preparing for Installation

8 techsupport@ireyee.com

but also increases the likelihood of communication failures. The risk of electrostatic adsorption increases when

the indoor relative humidity is low.

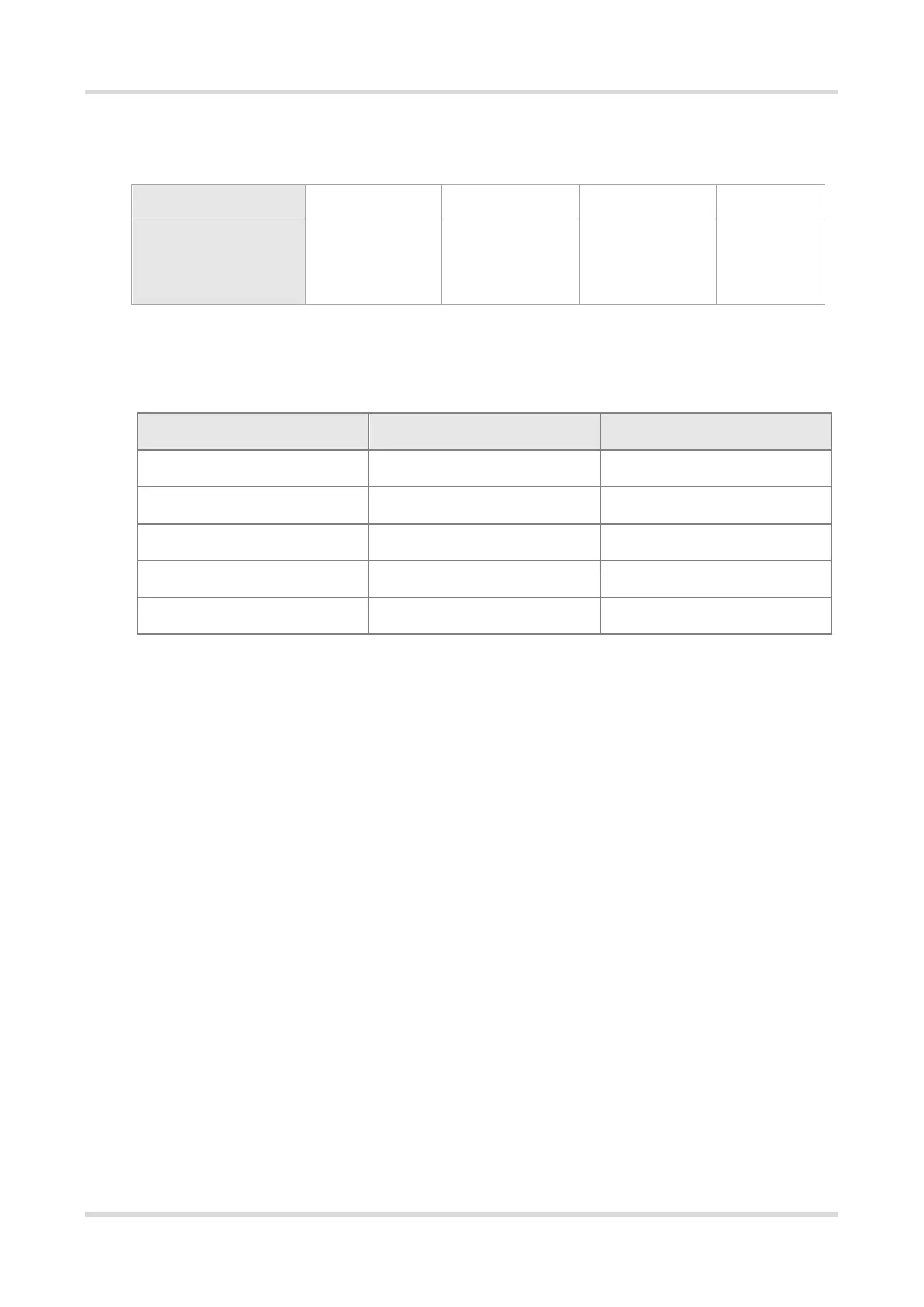

The following table describes the requirements for the dust content and granularity.

Max. Concentration

(Number Of

Particles/m

3

)

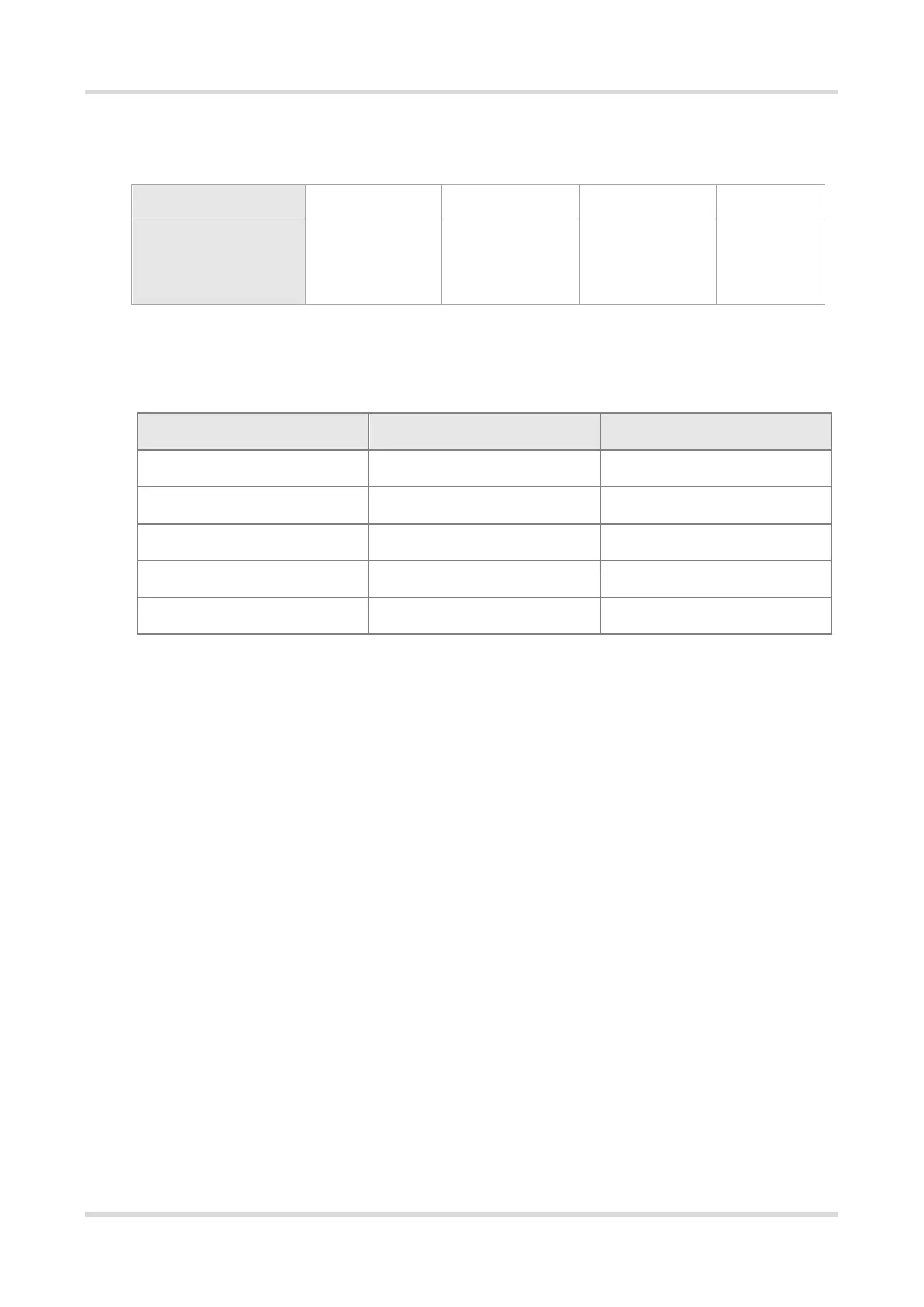

In addition to dust, the device also has specific requirements regarding the presence of harmful gases such as

hydrochloric acid sulfides in the air at the installation site. These gases can cause accelerated corrosion of

metals and aging of certain components. The following table describes the specific limits for harmful gases

including SO

2

, H

2

S, NO

2

, NH

3

, and Cl

2

in the installation site.

2.2.3 ESD Protection Requirements

This device is designed with rigorous anti-static procedures during circuit design. However, excessive static

electricity can still cause damage to its circuit board. Static electricity in the communication network connected

to the device mainly originates from two sources:

Outdoor high-voltage transmission lines, lightning and other external electric fields; and

Internal systems such as indoor flooring materials and overall structure of the device.

To prevent damage caused by static electricity, pay attention to the following:

Keep the indoor installation environment clean and free of dust.

Maintain appropriate temperature and humidity.

2.2.4 Anti-interference

Anti-interference measures primarily target electromagnetic and current interferences. The following

requirements should be met to ensure effective mitigation of interference:

Take effective measures to prevent interference from power grid to the power supply system.

Keep the device away from the grounding facility or lightning and grounding facility of the power device as

much as possible.

Keep the device far away from high-frequency current devices such as high-power radio transmitting stations

and radar launchers.

Loading...

Loading...