Form CP-MAPS-D12 with FX05, P/N 209341 Rev 4, Page 21

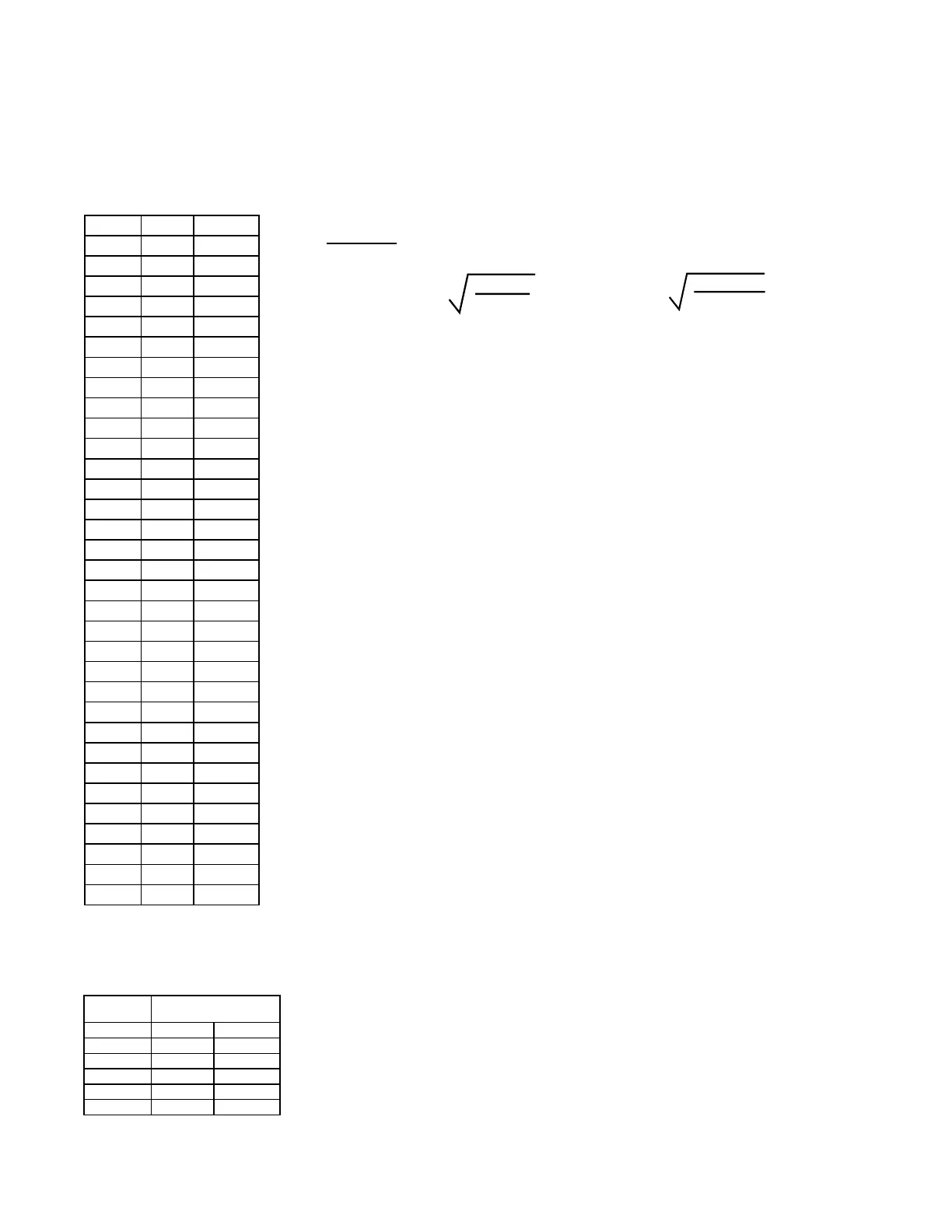

Sensor Data for

Johnson A99 Series

Temperature Sensors

- Resistance vs

Temperature (applies

to both discharge and

outside air sensor)

°F °C Ohms

-40 -40 613

-31 -35 640

-22 -30 668

-13 -25 697

-4 -20 727

5 -15 758

14 -10 789

23 -5 822

32 -0 855

41 5 889

50 10 924

59 15 960

68 20 997

77 25 1035

86 30 1074

59 35 1113

104 40 1153

113 45 1195

122 50 1237

131 50 1279

140 60 1323

149 65 1368

158 70 1413

167 75 1459

176 80 1506

185 85 1554

194 90 1602

203 95 1652

212 100 1702

221 105 1753

230 110 1804

239 115 1856

248 120 1908

1. Determine the appropriate distance from the unit. Be sure there is

sufcient distance from the outlet to have a good mixture of discharge air

temperature. According to the latest edition of AMCA Standard 201, in

straight ducts, the air is typically well mixed a minimum of ve equivalent

duct diameters from the discharge of the unit with equivalent duct diameter

dened as equal to the square root of 4AB/3.14. “A” and “B” are the duct

cross-sectional dimensions.

Example: Supply ductwork cross-sectional dimension is 24” x 12”

(610mm x 305mm).

5 x

= 96” 5 x

= 2435mm

Locate the sensor a minimum of 96” (2435mm) from the

outlet of the unit.

Important NOTES: If the length of the discharge duct is less than 12 ft

(3.7M), a mixing vane is recommended for mixing the discharge air.

Do not mount the sensor in the ductwork after a split in the supply as that

will cause loss of control in the duct that does not house the sensor.

2. Determine the location and orientation of the sensor holder assembly.

The position of the sensor holder in the duct is also important. In horizontal

ductwork, locate the sensor assembly in the top, middle of the duct with the

sensor holder extending vertically down into the center of the airstream. In

vertical ductwork, locate the sensor assembly in the middle of the side of

the duct that corresponds with the top middle of the discharge outlet. The

sensor holder will extend horizontally into the center of the airstream.

Push the sensing element into the clip attached to the inside of the sen-

sor holder. Turn the metal holder so that the element will be shielded from

direct airow and will sense the temperature in the airstream as it ows

through the holes in the sensor holder.

At the location selected, mark the diamond-shaped hole required for the

sensor holder. Cut the hole no larger than required for the holder, approxi-

mately 1” x 1” (25mm x 25mm).

In the electrical box portion of the sensor holder, determine where the sen-

sor wire should come through the box and remove the knockout at that

location.

3. Attach the sensor holder assembly.

Slide the sensor holder into the

opening in the ductwork. Using four eld-provided No. 6 sheetmetal

screws, attach the box to the ductwork. Attach a eld-supplied cable con-

nector to the box, run the sensor wire out, and attach the cover to the box.

4.

Run the sensor wire to the unit. Digital control inputs are low-current,

resistance-based signals. The manufacturer recommends for optimum

temperature control performance that the analog and digital inputs (zone

sensors, discharge air sensors, etc.) that are connected to the FX05 con-

troller be routed to the unit in one of the following manners:

• In separate eld-supplied conduits, isolated from 24VAC controls and

line voltage power to the unit,

OR

• If the FX05 wires are to be run in the same eld-supplied conduit as

the 24 VAC control wiring, the FX05 wiring must be completed using

shielded cable and bundled separately from 24 VAC control wiring. The

shield must be drained at the unit and taped on the opposite end.

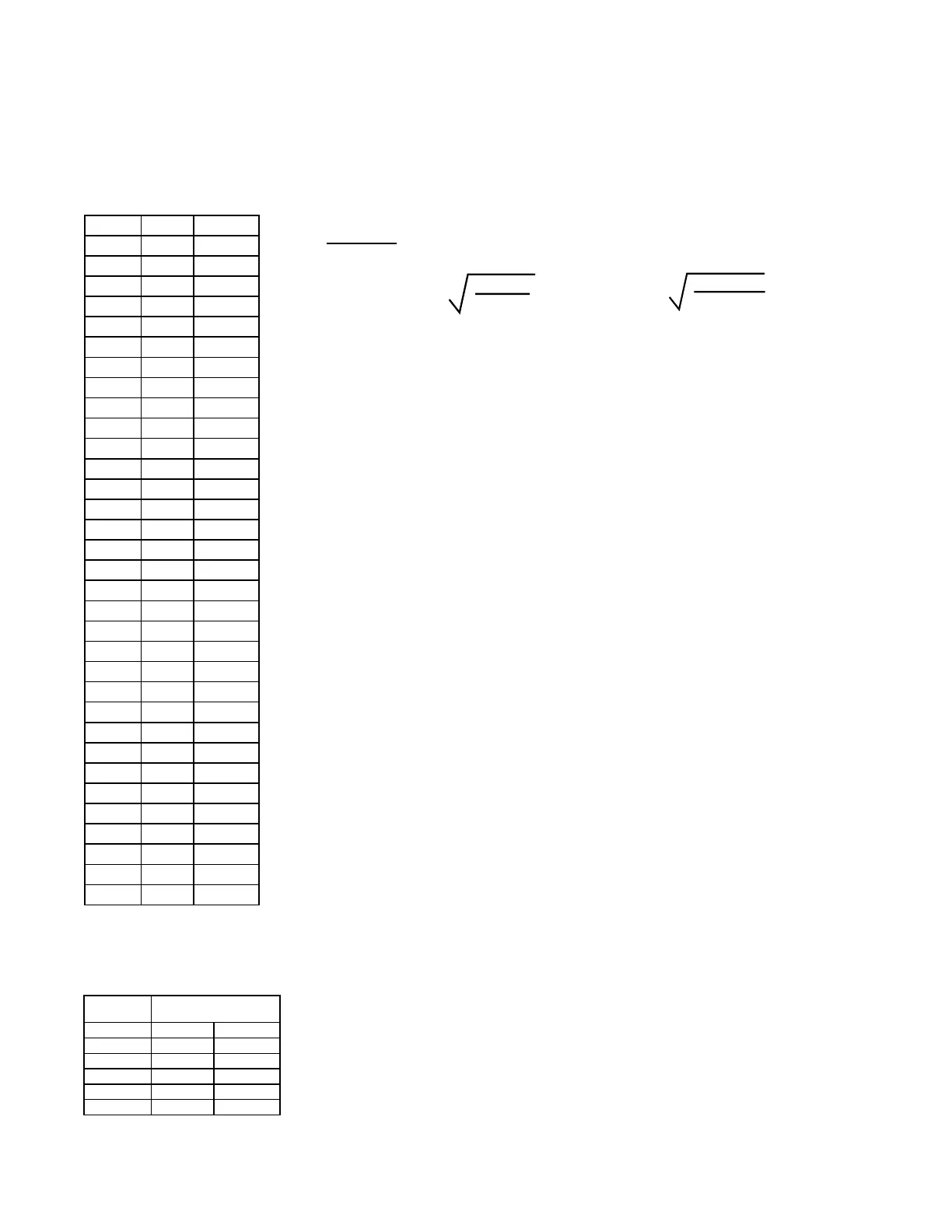

NOTE: Wire supplied with

the sensor is 22 AWG.

Maximum Sensor

Wire Length for

less than 1°F Error

Wire

Gauge

Maximum Sensor Wire

Length

AWG Feet Meters

14 800 244

16 500 152

18 310 94

20 200 61

22 124 38

Instructions for Installing Sensor in Discharge Duct

Loading...

Loading...