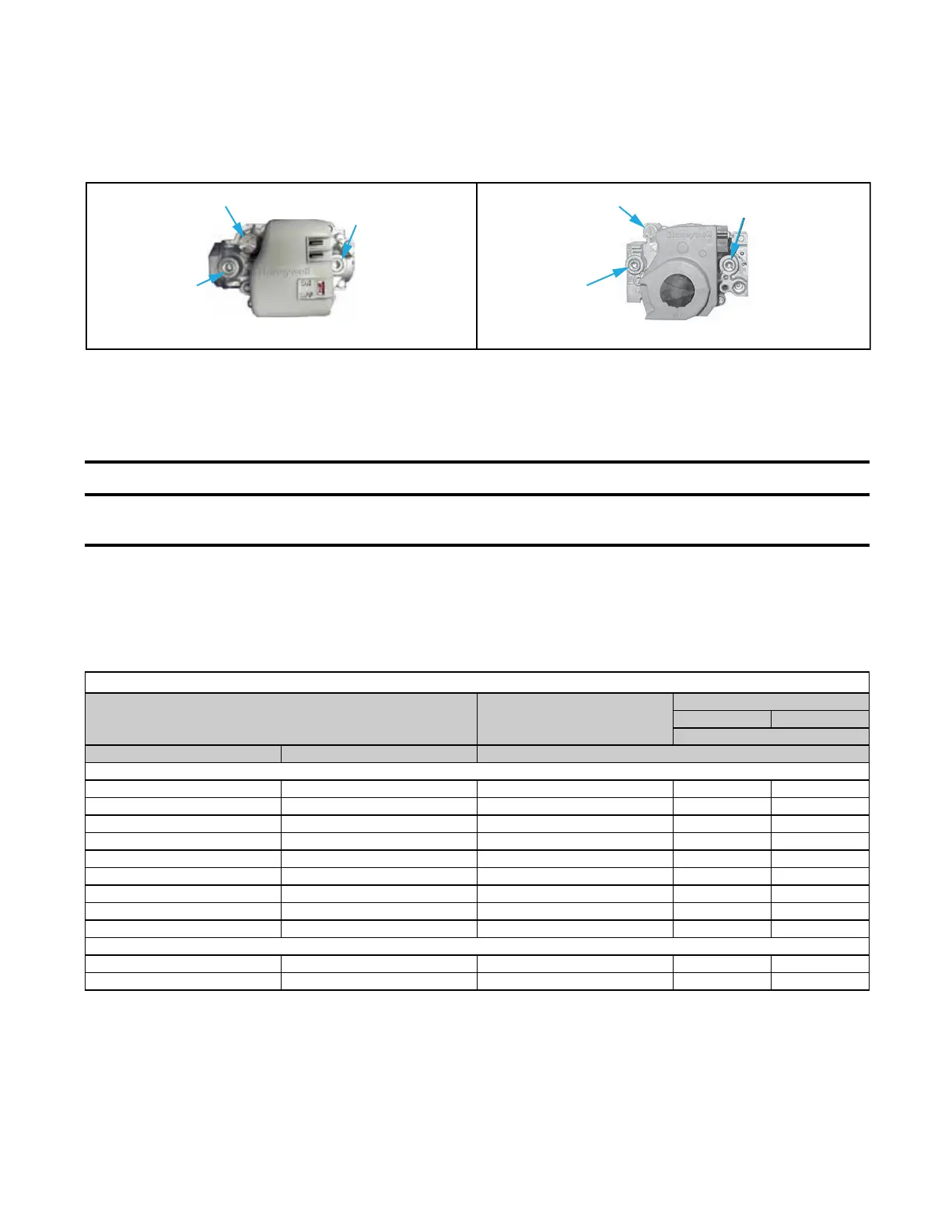

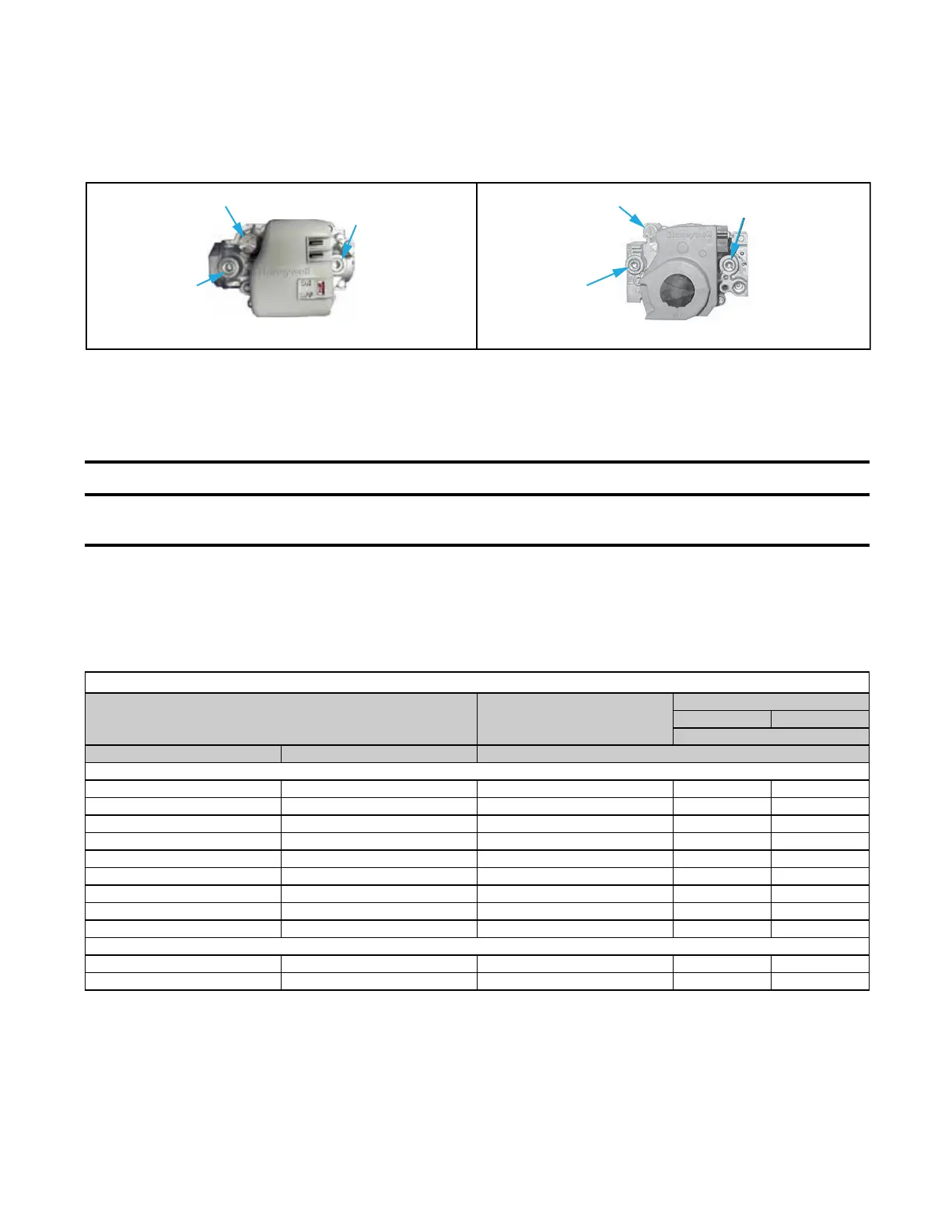

Figure 28. Gas Valves

3. Open manual valve and operate heater. Depress and hold door safety switch.

4. Cycle burner once or twice to properly seat adjustment spring in valve and observe manometer gauge to measure

outlet pressure of gas valve.

⚠ CAUTION ⚠

DO NOT bottom out the gas valve regulator screw. This can result in excessive overfire and heat

exchanger failure due to unregulated manifold pressure.

5. If manometer reading does not indicate that valve outlet pressure is in accordance with Table 23, remove cap

from regulator screw(s) (see Figure 28) and adjust pressure by turning regulator screw IN (clockwise) to increase

pressure or OUT (counterclockwise) to decrease pressure.

6. When manometer reading indicates that outlet pressure is in accordance with Table 23, disconnect manometer

and install cap(s) on regulator screw(s).

Table 23. Required Manifold (Outlet) Gas Pressure

Elevation Natural Gas

Unit Size

130, 260 180, 310

Propane

Feet Meters Manifold Pressure (IN WC)

US

0–2000 0–610 3.5 10.0 9.5

2001–3000 611–915 3.1 8.8 8.4

3001–4000 916–1220 3.0 8.5 8.0

4001- 5000 1221–1525 2.8 8.1 7.7

5001–6000 1526–1830 2.7 7.7 7.3

6001–7000 1831–2135 2.6 7.4 7.0

7001–8000 2136–2440 2.5 7.1 6.7

8001–9000 2441–2745 2.4 6.7 6.3

9001–10,000 2746–3045 2.2 6.4 6.0)

Canada

0–2000 0–610 3.5 10.0 9.5

2001–4500 611–1373 2.8 8.1 7.7

1/8-INCH OUTPUT

PRESSURE TAP

INLET

PRESSURE TAP

REGULATOR SCREW

UNIT SIZES 260 AND 310

UNIT SIZES 130 AND 180

1/8-INCH OUTLET

PRESSURE TAP

INLET

PRESSURE TAP

REGULATOR SCREW

ADJUSTMENTS—CONTINUED

Measure and Adjust Manifold (Outlet) Gas Pressure—Continued

Measure and Adjust Manifold Gas Pressure—Elevation ≤2,000 Feet (≤610 Meters)—Continued

44

I-UEZ (04-21) 1034347-0

Loading...

Loading...