11

4.0 INSTALLATION

4.4.3 Liquid Line Selection

The purpose of the liquid line is to transport warm

sub-cooled liquid refrigerant between the outdoor

unit to the indoor unit. It is important not to allow the

refrigerant to ash into superheated vapor prior to en-

tering the expansion device of the indoor coil or outdoor

unit. Flashing of refrigerant can occur for the following

reasons:

• Low refrigerant charge.

• Improperly selected liquid line size.

• Absorption of heat prior to expansion device.

• Excessive vertical separation between the outdoor

unit and indoor coil.

• Restricted liquid linear lter drier.

• Kinked liquid line.

The total pressure drop allowed for the liquid line is 50

PSI [345 kPa]. The procedure for selecting the proper

liquid line is as follows:

• Measure the total amount of vertical separation be-

tween the outdoor unit and indoor coil.

• Measure the total indoor length of liquid line re-

quired.

• Add all of the equivalent lengths associated with any

ttings or accessories using Table 1.

• Add the linear length to the total tting equivalent

length. This will equal your total equivalent line

length.

• Reference Table 2 to verify the calculated equivalent

length is acceptable with the required vertical sepa-

ration and diameter of liquid line.

Example: A 3-ton unit is installed 25’ below the indoor

unit, requires 75’ of 1/2” diameter liquid line, 3/4” suction

line, 4 90° LR elbows, and a lter drier.

• Fitting Equivalent Length (ft.) = (4 × .9’) + 6’ = 9.6’

• Total Equivalent Length (ft.) = 75’ + 9.6’ = 84.6’

This application is acceptable because the 25’

vertical rise is less than the maximum rise of 50’ for

this application. This application is also considered to

have a lone line set since 75’ exceeds the limit of 0 feet.

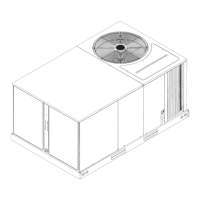

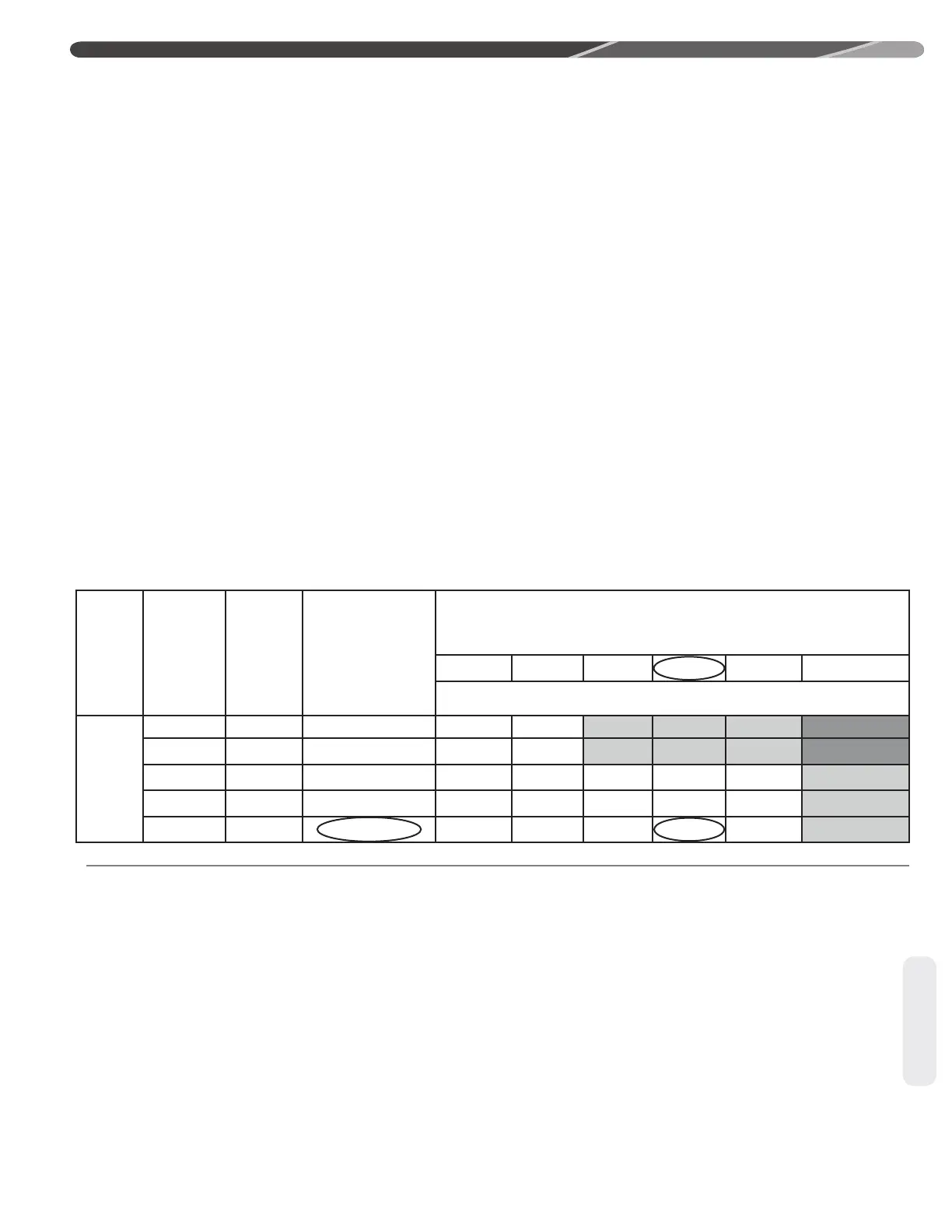

Unit

Size

Allowable

Liquid

Line

Size

Allowable

Suction

Line

Size

Use Long Line

Guidelines for

Linear Line

Lengths Greater

Than Shown

Below

(Feet)

Outdoor Unit ABOVE or BELOW Indoor Unit

Equivalent Length (Feet)

<25 26-50 51-75 76-100 101-125 126-150

Maximum Vertical Separation (Outdoor Unit Below Indoor Unit)* / Capacity Multiplier

3 Ton

5/16” 5/8” 20 25 / 0.99 50 / 0.97 50 / 0.95 50 / 0.93 36 / 0.91 NR

3/8” 5/8” 15 25 / 0.99 50 / 0.97 50 / 0.95 50 / 0.93 50 / 0.91 NR

5/16” 3/4” 20 25 / 1.00 50 / 0.99 50 / 0.99 50 / 0.98 36 / 0.97 18 / 0.96

3/8” 3/4” 15 25 / 1.00 50 / 0.99 50 / 0.99 50 / 0.98 50 / 0.97 50 / 0.96

1/2” 3/4” 0 25 / 1.00 50 / 0.99 50 / 0.99 50 / 0.98 50 / 0.97 50 / 0.96

(Excerpt from Table 2A)

4.4.4 Suction Line Selection

The purpose of the suction line is to return super-

heated vapor to the condensing unit from the

indoor coil. Proper suction line sizing is important be-

cause it plays an important role in returning oil to the

compressor to prevent potential damage to the bearings,

valves, and scroll sets. Also, an improperly sized suction

line can dramatically reduce capacity and performance

of the system. The procedure for selecting the proper

suction line is as follows:

• Determine the total linear length of suction line

required.

• Add all of the equivalent lengths associated with any

ttings or accessories using Table 1.

• Add the linear length and total tting equivalent

length. This will equal your total equivalent line

length.

• Reference Table 2 to verify that the calculated equiv-

alent length falls within the compatibility region of the

chart.

• Verify capacity loss is acceptable for the application.

Tubing

Loading...

Loading...