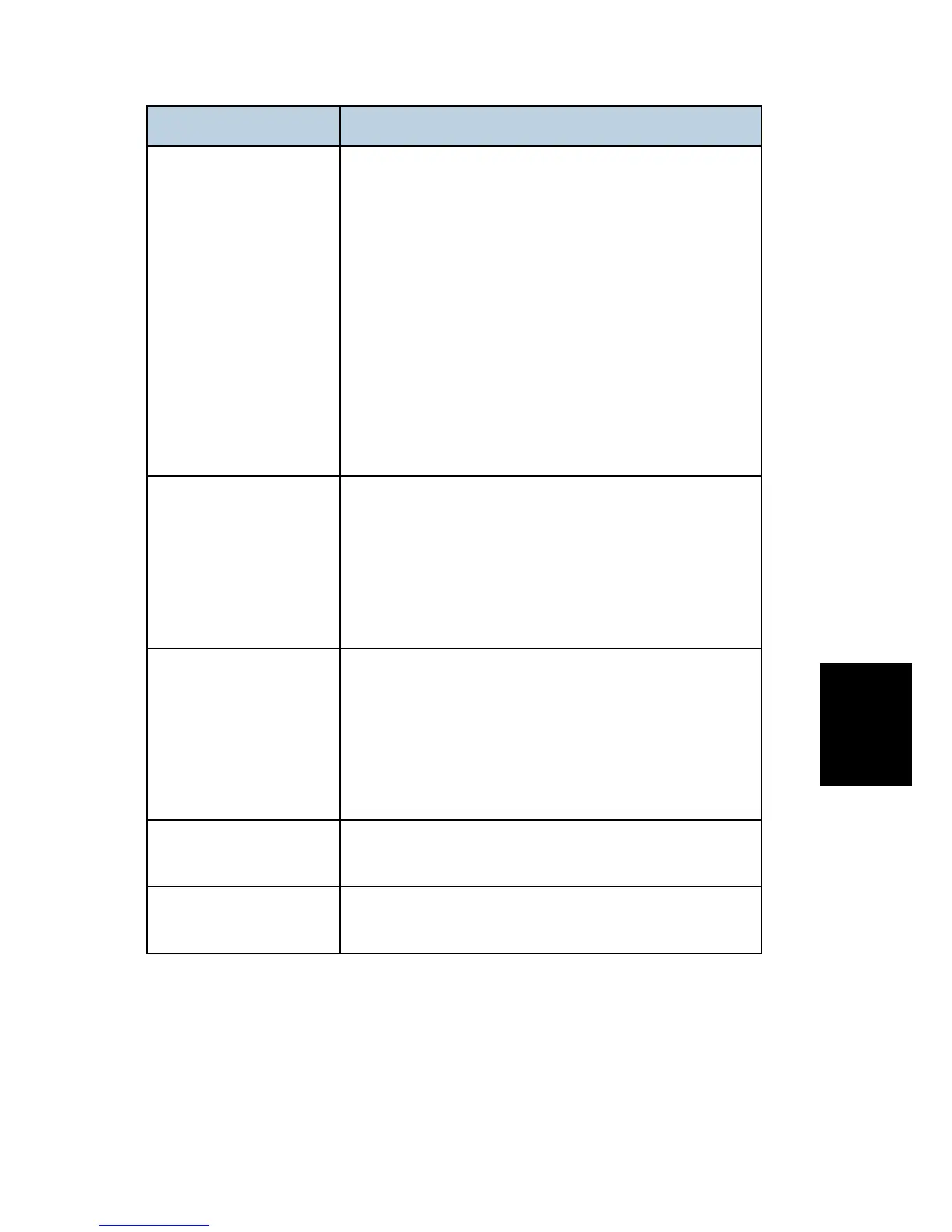

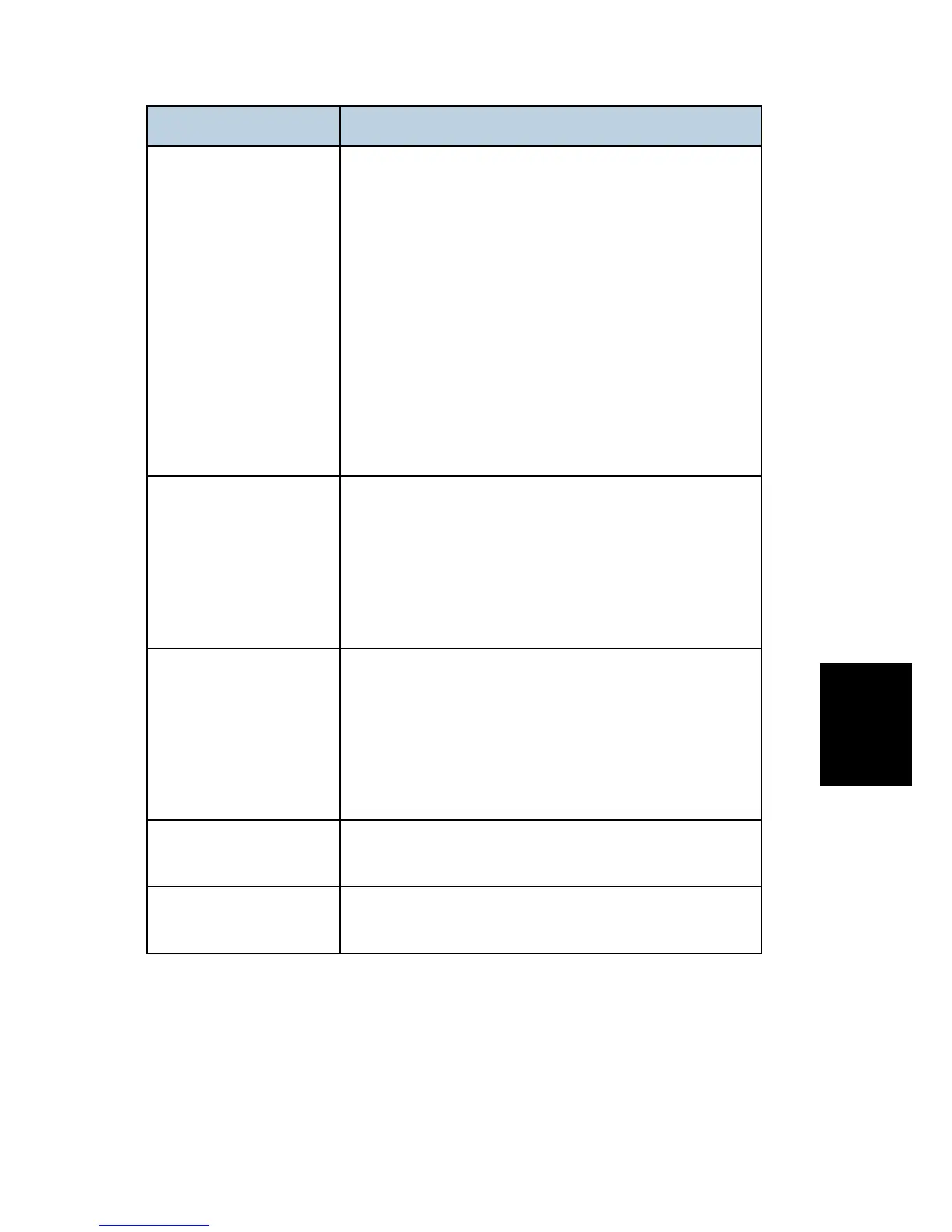

problem Cause/Solution

Multiple sheets of paper

are fed at one time.

Fan the paper well before loading. Also make sure that

the edges are even by tapping the stack on a flat

surface such as a desk.

Make sure that the paper guides are in the right position.

Use supported types of paper.

Load paper only as high as the upper limit markings on

the paper guide.

Make sure that the friction pads and paper feed rollers

are clean.

Check that paper was not added while there was still

some left in the tray.

Only add paper when there is none left in the tray.

Paper gets wrinkles.

Deterioration of the hot roller or the pressure roller.

Paper is damp. Use paper that has been stored

properly.

Paper is too thin.

If there are gaps between the paper and the paper

guides, adjust the paper guides to remove the gaps.

The printed paper is

curled.

Load the paper upside down in the paper tray.

If the paper curl is severe, take prints from the output

tray more frequently.

Paper is damp. Use paper that has been stored

properly.

Adjust with “Curl Control mode” in the SP Mode 3.

Images are printed

diagonally to the pages.

If there are gaps between the paper and the paper guides,

adjust the paper guides to remove the gaps.

Printed envelopes come

out creased.

Check if the levers for printing on envelopes inside the rear

cover are properly set. Lower the levers.

Loading...

Loading...