The 141 and 161 can be powered in a variety of ways,

including operation by hand or with various RIDGID

Threading Machines and Power Drives.

Figure 1 – Model 141 Receding Geared Threader

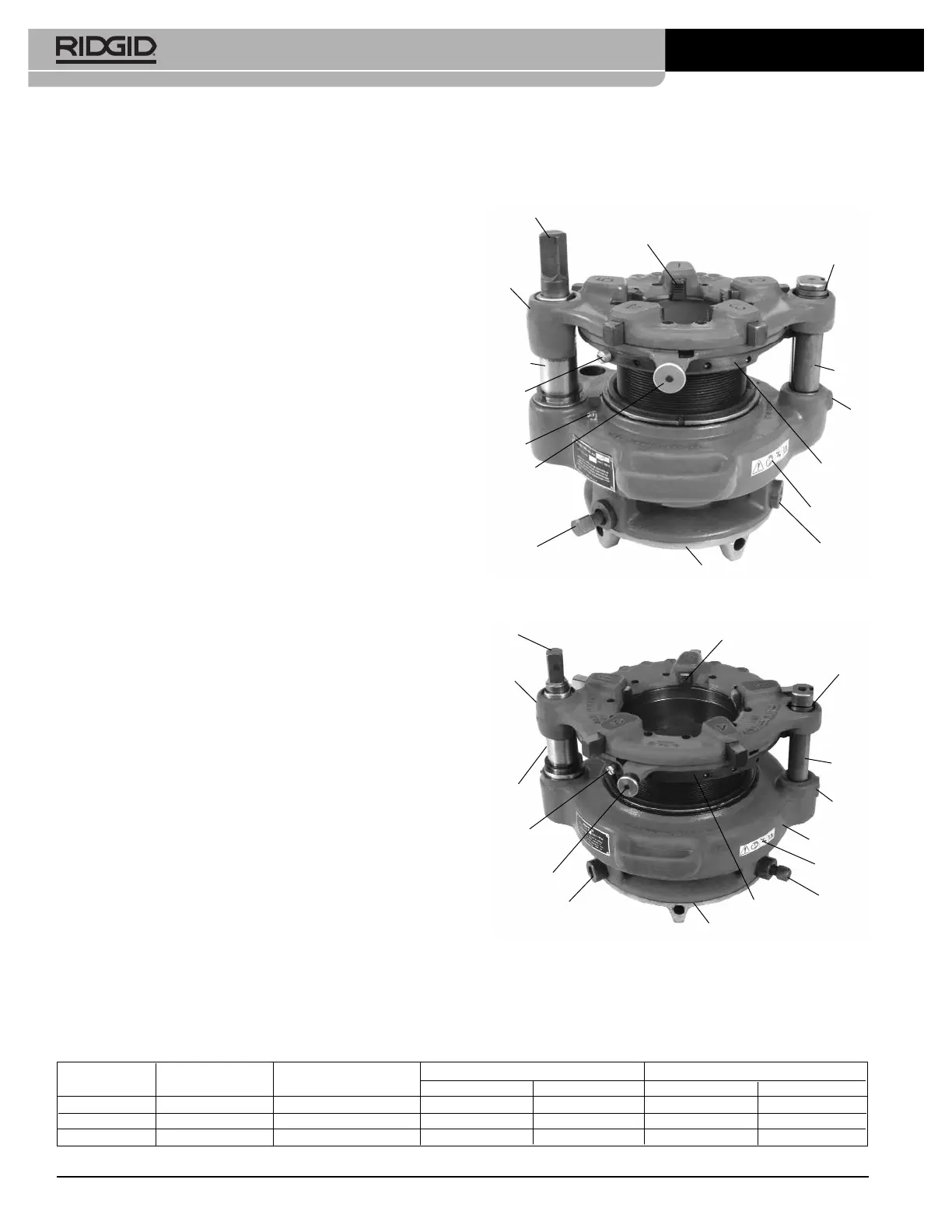

Figure 2 – Model 161 Receding Geared Threader

• Follow instructions on proper use of this machine.

Do not use for other purposes such as drilling

holes or turning winches. Other uses or modifying

this power drive for other applications may increase the

risk of serious injury.

• Read and understand the instructions and warn-

ings for all equipment being used including Thread -

ing Machines and Power Drives before operating

the Geared Threaders. Failure to follow all warnings

and instructions may result in property damage and/or

serious injury.

• Do not use this machine if the foot switch is bro-

ken or missing. Foot switch is a safety device that

provides better control by letting you shut off the motor

in various emergency situations by removing your

foot from the switch. For example: if clothing should

become caught in the machine, the high torque will

continue pulling you into the machine. The clothing

itself can bind around your arm or other body parts with

enough force to crush or break bones.

The EC Declaration of Conformity (890-011-320.10) will

accompany this manual as a separate booklet when

required.

If you have any question concerning this RIDGID

®

product:

– Contact your local RIDGID distributor.

– Visit www.RIDGID.com to find your local RIDGID con-

tact point.

– Contact RIDGID Technical Services Department at

rtctechservices@emerson.com, or in the U.S. and

Canada call (800) 519-3456.

Description, Specifications and

Standard Equipment

Description

The RIDGID

®

Model 141 and 161 Receding Geared

Thread ers are designed to thread 2

1

/

2

" to 4" and 4" to 6"

pipe, respectively. A cam type workholder is used to grip

the pipe while the die head cuts the threads. A clutch is

included to prevent jamming at the end of the thread.

The threaders can be used for both tapered and straight

right hand threads with a simple adjustment. See specifi-

cations for NPT and BSPT versions.

4

Model 141/161 Receding Geared Threaders

Model No. Thread Type Threads Per Inch

Nominal Capacity Weight

inch mm lb kg

141 NPT 8 2½ to 4 65 to 100 93 42.2

141 BSPT 11 2½ to 4 65 to 100 93 42.2

161 NPT 8 4 to 6 100 to 150 158 71.7

Die (Set of 5)

Thread

Size Marks

Guide

Post

Gear Case

Selector Plate

Die Head

Stop

Screw

Pinion

Sleeve

Guide

Post

Die

(Set of 5)

Drive Shaft

Clamp Screw

Cam Plate

Knob (2)

Thread Size

Marks )

Selector

Plate

Die Head

Stop

Screw

Work Holder Jaws (3)

Pinion

Sleeve

Grease

Fitting

Work Holder

Work Holder

Jaws (2)

Warning

Label

Guide

Post

Screw

Specifications

Drive Shaft

Work Holder

Guide

Post

Screw

Clamp

Screw

Warning

Label

Cam Plate

Knob (2)

Loading...

Loading...