Maintenance

39

20095042

6.1 Notes on safety for the maintenance

The periodic maintenance is essential for the good operation, safe-

ty, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and to

keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking opera-

tions:

6.2 Maintenance programme

6.2.1 Maintenance frequency

6.2.2 Checking and cleaning

Combustion

The optimum calibration of the burner requires an analysis of the

flue gases. Significant differences with respect to the previous

measurements indicate the points where more care should be ex-

ercised during maintenance.

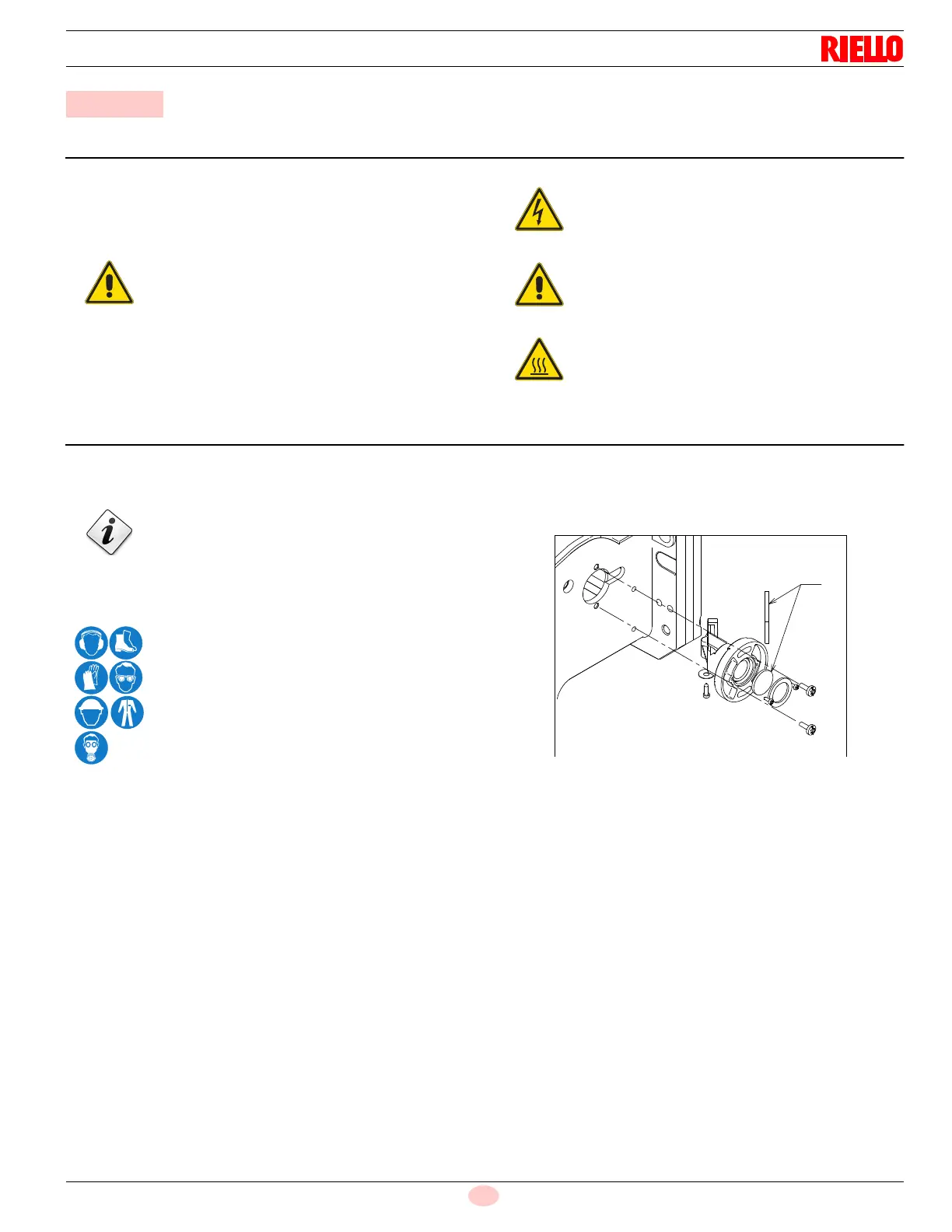

Combustion head

Open the burner and make sure that all components of the com-

bustion head are in good condition, not deformed by the high tem-

peratures, free of impurities from the surroundings and correctly

positioned. If in doubt, disassemble the elbow fitting 7)(Fig. 53,

page 41).

Burner

Check for excess wear or loose screws. Also make sure that the

screws securing the electrical leads in the burner connections are

fully tightened.

Clean the outside of the burner.

Flame inspection window

Clean the flame inspection window 1)(Fig. 51).

Nozzles

It is advisable to replace nozzles once a year during periodical

maintenance.

Do not clean the nozzle openings;

Hoses

Check that these are in good conditions.

Fan

Check to make sure that no dust has accumulated inside the fan or

on its blades, as this condition will cause a reduction in the air flow

rate and provoke polluting combustion.

6 Maintenance

The maintenance interventions and the calibration

of the burner must only be carried out by qualified,

authorised personnel, in accordance with the con-

tents of this manual and in compliance with the

standards and regulations of current laws.

Disconnect the electrical supply from the burner by

means of the main system switch.

Turn off the fuel interception tap.

Wait for the components in contact with heat sourc-

es to cool down completely.

The gas combustion system should be checked at

least once a year by a representative of the manu-

facturer or another specialised technician.

The operator must use the required equipment dur-

ing maintenance.

Loading...

Loading...