20106891

20

Installation

4.5 Preparing the boiler

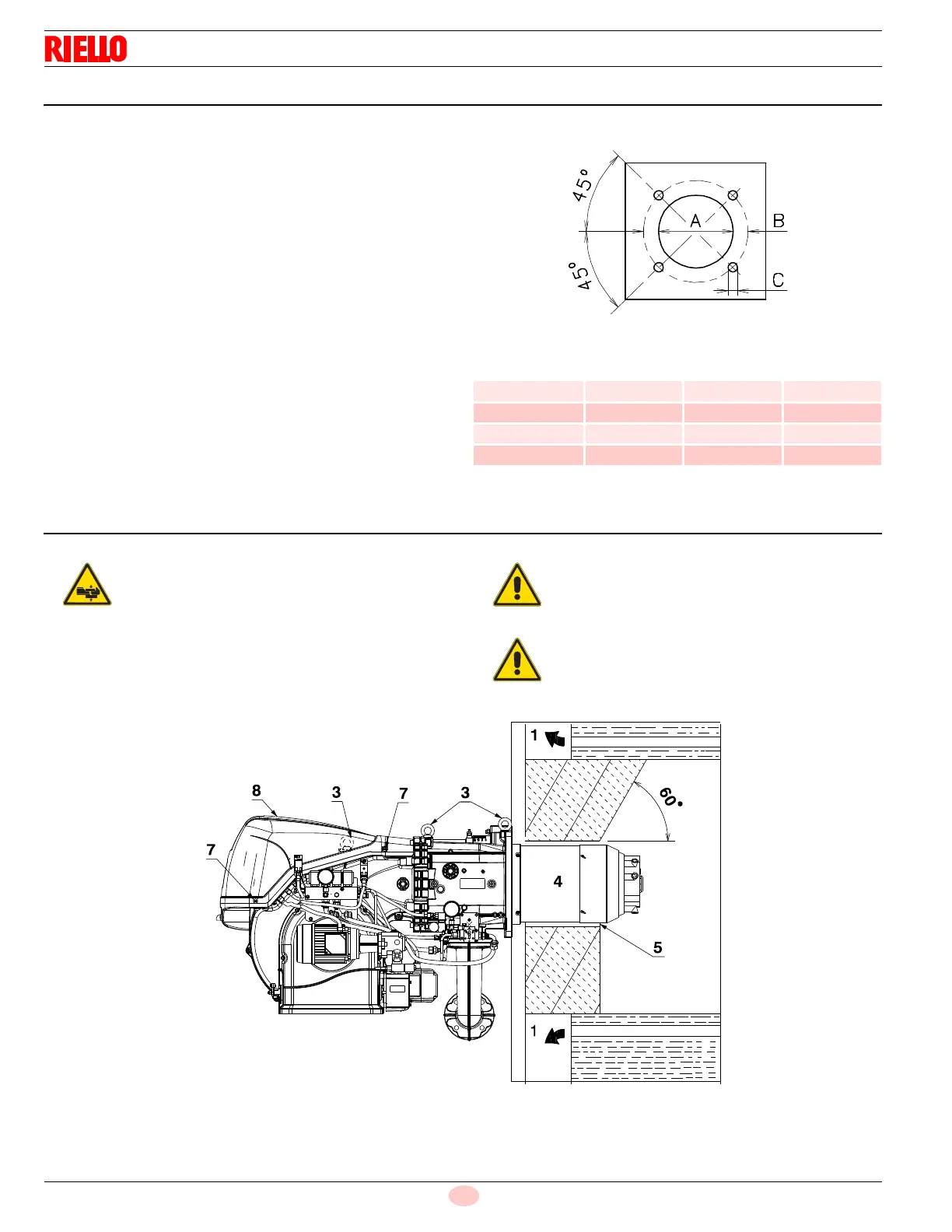

4.5.1 Boring the boiler plate

Drill the combustion chamber locking plate as shown in Fig. 11.

The position of the threaded holes can be marked using the ther-

mal screen supplied with the burner.

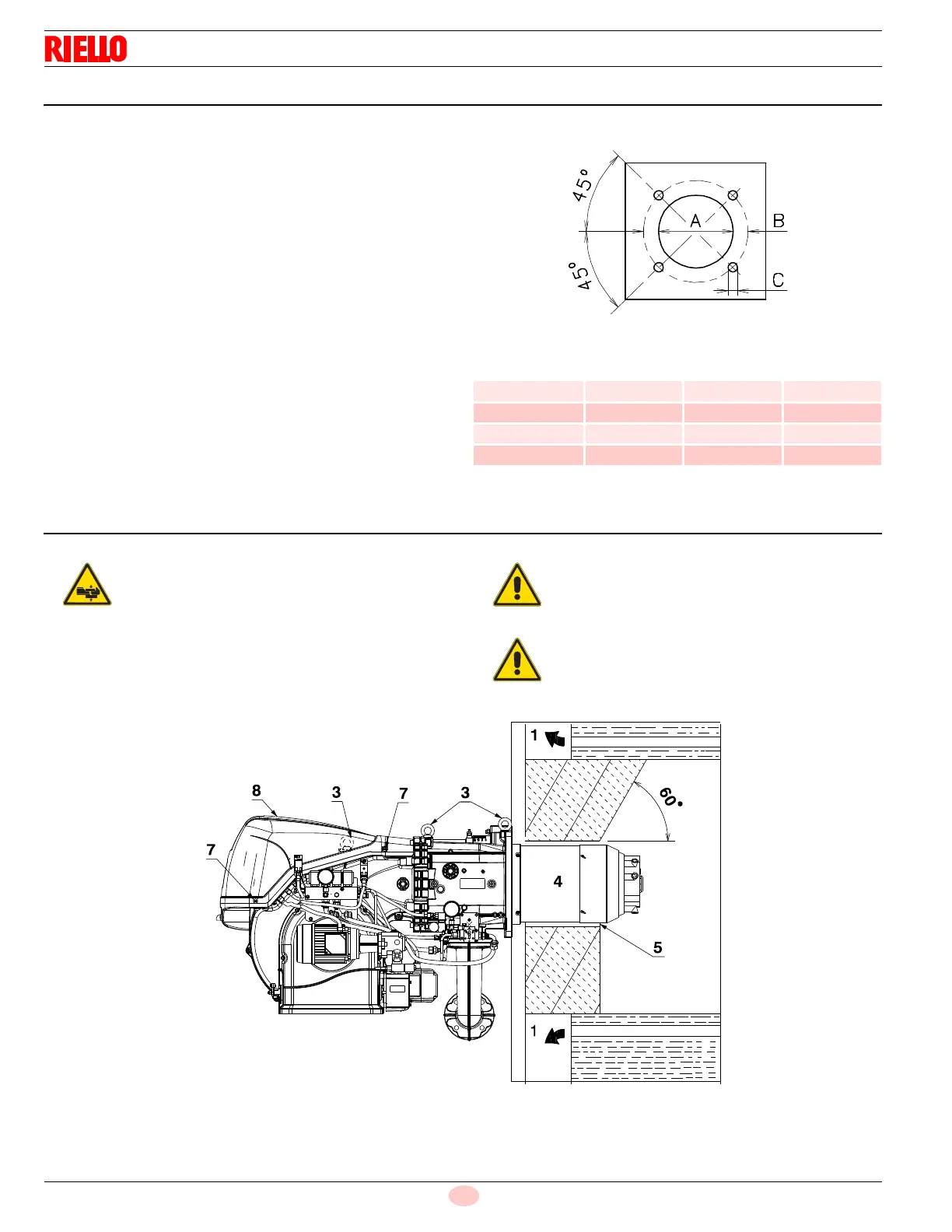

4.5.2 Blast tube length

The length of the blast tube must be selected according to the indi-

cations provided by the manufacturer of the boiler, and in any case

it must be greater than the thickness of the boiler door complete

with its fettling.

For boilers with front flue passes 1)(Fig. 18 on page 23) or flame in-

version chamber, a protection in refractory material 5) must be in-

serted between the boiler fettling 2) and the blast tube 4).

The refractory can have a conical shape (minimum 60°).

This protective fettling must not compromise the extraction of the

blast tube.

For boilers with a water-cooled front piece, a refractory lining 2)-

5)(Fig. 18 on page 23) is not necessary, unless expressly request-

ed by the boiler manufacturer.

Tab. K

4.6 Securing the burner to the boiler

Fit the heat insulation supplied onto the blast tube (4)(Fig. 12).

Fit the entire burner onto the boiler hole prepared previously,

and fasten with the screws supplied.

inch ABC

RLS 280/E 13

1

/

4”

17

13

/

16”

3

/

4”

coarse

RLS 310/E 13

1

/

4”

17

13

/

16”

3

/

4”

coarse

RLS 410/E 13

1

/

4”

17

13

/

16”

3

/

4”

coarse

RLS 510/E 13

1

/

4”

17

13

/

16”

3

/

4”

coarse

Prepare a suitable lifting system using the rings

3)(Fig. 12), after removing the fixing screws 7) of the

casing 8).

The seal between burner and boiler must be air-

tight.

The manufacturer declines any and every re-

sponsibility for any possible lifting movements,

different from those indicated in this manual.

Loading...

Loading...