20106891

28

Installation

4.13 Hydraulic connections

The pumps are equipped with a by-pass that connects return

line and suction line.

The pumps are installed on the burner with the by-pass closed

by screw 6)(Fig. 21). It is therefore necessary to connect both

hoses to the pump.

Remove the plugs from the suction and return connections of

the pump.

Insert the hose connections with the supplied seals into the

connections and screw them down.

Install the hoses where they cannot be stepped on or come

into contact with hot surfaces of the boiler and where they do

not hamper the opening of the burner.

Now connect the other end of the hoses to the suction and

return lines by using the supplied nipples.

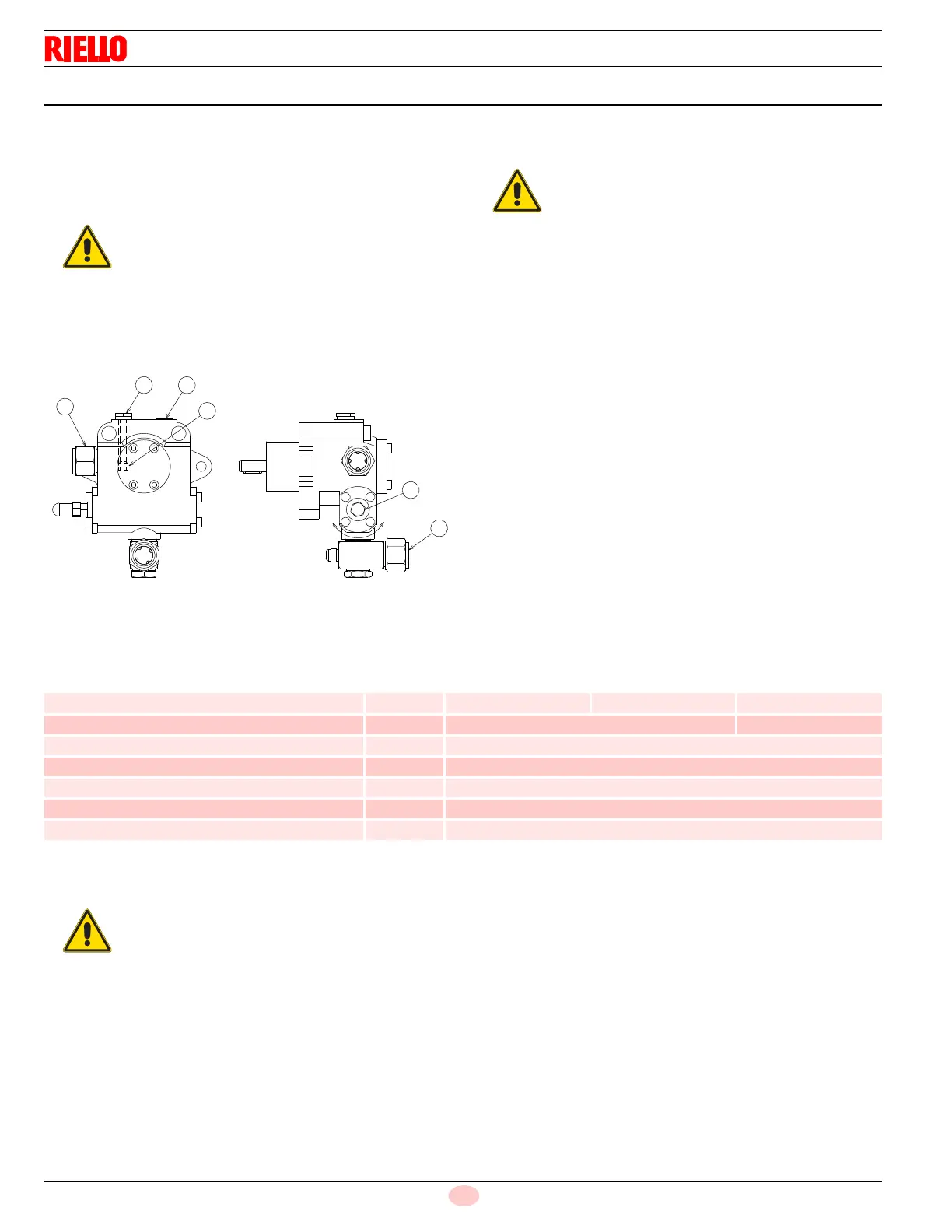

4.13.1 Pump

Key (Fig. 21)

1 Suction line G 3/4” NPT

2 Return line G 3/4” NPT

3 Vacuometer connection G 1/4”

4 Pressure adjuster

5 By-pass screws

6 Gauge connection G 1/4”

Technical data

Tab. N

Priming pump

In order for the pump (Fig. 21) to self-prime, it is vital that the

screw 4) of the pump be loosened to vent the air contained in

the suction line.

Start the burner by closing the remote controls.

As soon as the burner starts, check the direction of rotation of

the fan blade.

The pump can be considered to be primed when the light oil

starts coming out of the screw 4). Close the burner and undo

the screws 4).

The time required for this operation depends upon the diameter

and length of the suction tubing.

If the pump fails to prime at first start-up and the burner locks out,

wait approx. 15 seconds, reset the burner, and then repeat the

start-up operation.

And so on. After 5 or 6 starting operations allow 2 or 3 minutes for

the transformer to cool.

Do not light the flame sensor or the burner will lock out; the burner

should lock out anyway about 10 seconds after it starts.

The pump will break immediately if it is run with

the return line closed and the by-pass screw in-

serted.

Take care that the hoses are not stretched or twist-

ed during installation.

Pump model

TA3

(RLS 280-310/E)

TA4

(RLS 410/E)

TA5

(RLS 510/E)

Min. delivery rate at 300 PSI pressure GPH 218 290 403

Delivery pressure range PSI 102 - 580 102 - 435

Max. suction pressure PSI 7.0

Viscosity range cSt 3 - 75

Max. oil temperature °F 302 (150 °C)

Max. return pressure PSI 73.0

Pressure calibration in the factory PSI 300

Before starting the burner, make sure that the tank

return line is not clogged.

Obstructions in the line could cause the sealing or-

gan located on the pump shaft to break.

Loading...

Loading...