28 V53De Manual

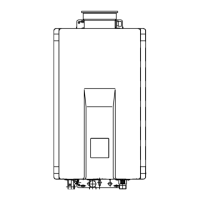

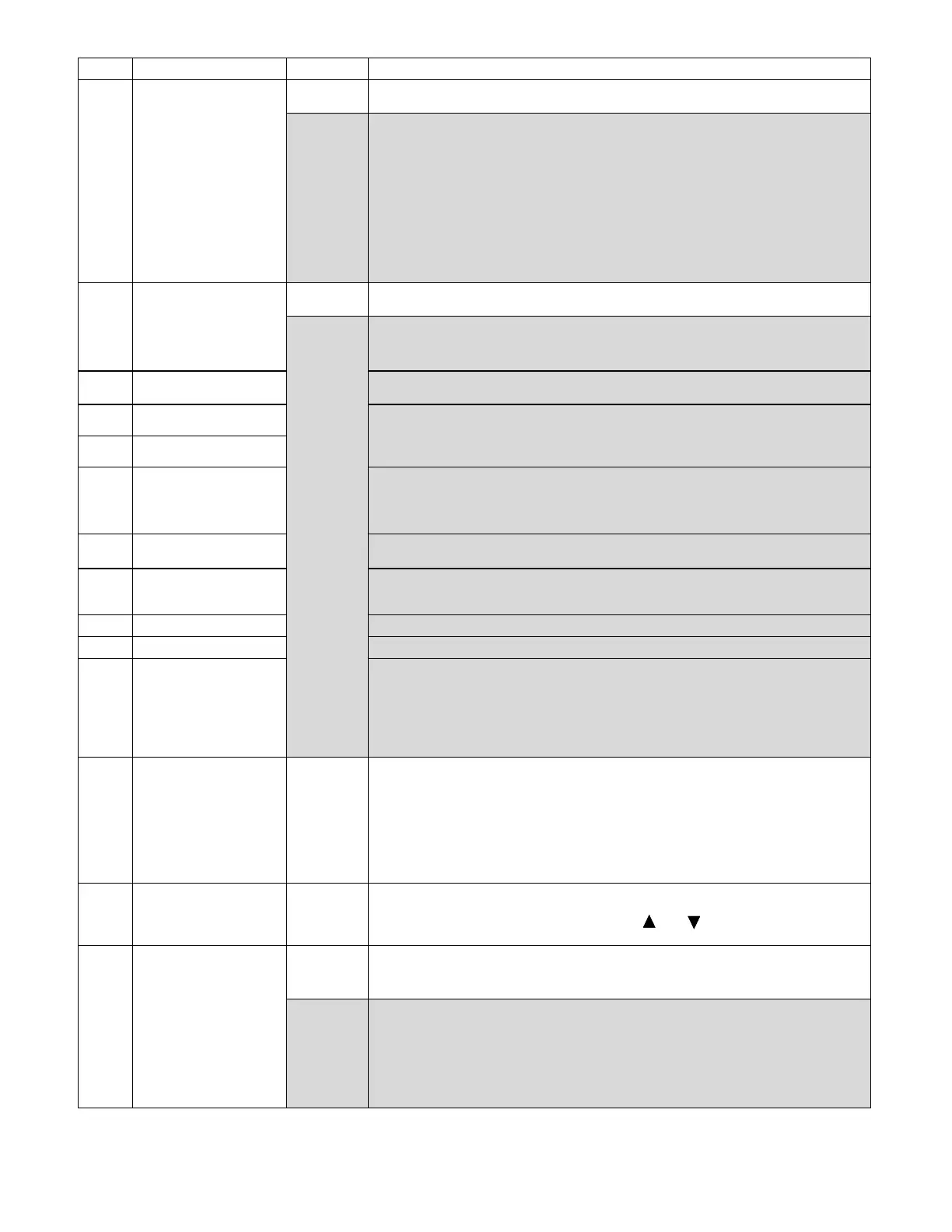

Code Denion Remedy

14

Thermal Fuse has

acvated

Check for restricons in air ow around unit and exhaust outlet.

licensed

professional

only

Check gas type of unit and ensure it matches gas type being used.

Check for low water ow in a circulang system causing short-cycling.

Ensure dip switches and programming parameters are set to the proper posion.

Check for foreign materials in combuson chamber and/or exhaust piping.

Check heat exchanger for cracks and/or separaons.

Check heat exchanger surface for hot spots which indicate blockage due to scale

build-up. Refer to instrucons in manual for ushing heat exchanger. Hard water

must be treated to prevent scale build up or damage to the heat exchanger.

Measure resistance of safety circuit.

Ensure high re and low re manifold pressure is correct.

Check for improper conversion of product.

16

Over Temperature

Warning (safety

shutdown because unit is

too hot)

Check for restricons in air ow around unit and exhaust outlet.

licensed

professional

only

Check for low water ow in a circulang system causing short-cycling.

Check for foreign materials in combuson chamber and/or exhaust piping.

Check for blockage in the heat exchanger.

19 Electrical Grounding

Check all components for electrical short.

32

Outgoing Water

Temperature Sensor

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

33

Heat Exchanger Outgoing

Temperature Sensor

41

Outside temperature

thermistor

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

52

Modulang Solenoid Valve

Signal

Check modulang gas solenoid valve wiring harness for loose or damaged terminals.

Measure resistance of valve coil.

61 Combuson Fan

Ensure fan will turn freely.

Check wiring harness to motor for damaged and/or loose connecons.

Measure resistance of motor winding.

70 PC Board Replace the PC Board.

71 Solenoid Valve Circuit Replace the PC Board.

72 Flame Sensing Device

Verify ame rod is touching ame when unit res.

Check all wiring to ame rod.

Remove ame rod and check for carbon build-up; clean with sand paper.

Check inside burner chamber for any foreign material blocking ame at ame rod.

Measure micro amp output of sensor circuit with ame present.

Replace ame rod.

LC#

LC0,

LC1...

Scale Build-up in Heat

Exchanger (when checking

maintenance code history,

“00” is substuted for

“LC”)

LC0~LC9 indicates that there is scale build up in the heat exchanger and that the heat

exchanger needs to be ushed to prevent damage. Refer to ushing instrucons in manual.

Hard water must be treated to prevent scale build up or damage to the heat exchanger.

To operate the water heater temporarily unl the heat exchanger can be ushed, push the On/

O buon on the temperature controller 5 mes. Repeated LC codes will eventually lockout

the water heater.

Please call Rinnai technical department.

FF

Maintenance Indicator

Placeholder in Diagnosc code history indicang that a service provider performed

maintenance or service.

Enter this code aer performing service by pressing (Up) , (Down) and ON/OFF

consecuvely. FF is visible on the monitor.

No

code

Nothing happens when

water ow is acvated.

Clean inlet water supply lter.

On new installaons ensure hot and cold water lines are not reversed.

Verify you have at least the minimum ow rate required to re unit.

licensed

professional

only

Check for cold to hot cross over. Isolate circulang system if present. Turn o cold water to the

unit, open pressure relief valve; if water connues to ow, there is bleed over in your plumbing.

Verify turbine spins freely.

Measure the resistance of the water ow control sensor.

If the display is blank and clicking is coming from the unit, disconnect the water ow servo

motor. If the display comes on then replace the water ow servo motor.

* See “Electrical Diagnoscs” on Technical Data Sheet located inside the front cover of water heater.

Loading...

Loading...