PUB. NO. FASTRAXC FEBRUARY 2008 11

FASTRAX

™

1. It is the responsibility of the buyer to provide electrical

service up to the control box with proper branch service

protection and an approved means of disconnect.

2. All control boxes should be mounted on the warm side

regardless of door mount side.

3. The incoming power terminals in the control box will not

accommodate wires larger than 12AWG. 20 or 30 Amp

service may be required for cable runs longer than 300’.

4. The control box is provided with class CC protective

fusing for the incoming power.

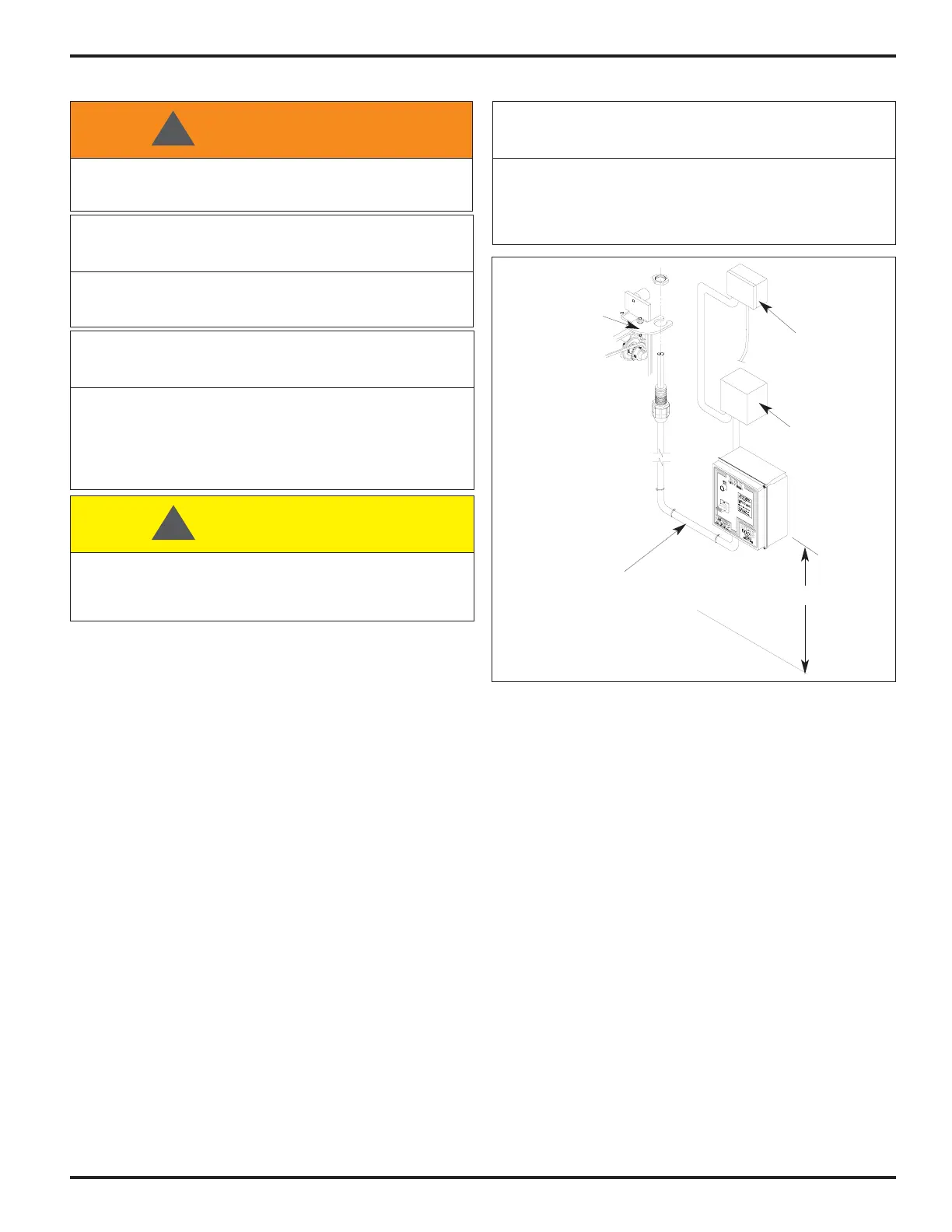

5. Mount the control box on a wall adjacent to the door at

approximately 54" above the floor level, Figure 20.

6. Run the control cable from the conduit mounting bracket

to the conduit fitting in the bottom of the control box.

NOTE: Make sure to route the cable so that it does not

interfere with the installation of the motor shroud.

If the flexible conduit is too long for the

installation, cut the protective outer casing and

leave 16" to 20" of wires. Do not connect the

conduit to the fitting on the control box until

correct conduit and wire length is achieved.

Local electrical codes may require the use of rigid

conduit, rather than flexible conduit. If required,

remove the control cables from the furnished

flexible conduit, install the rigid conduit in its place

and rewire. Make sure to remove and replace the

conduit connector in the bottom of the control box.

7. Drill a hole for the power supply cable (by others) in the

bottom of the control box using the proper connection to

maintain the NEMA rating on the enclosure. Incoming

3-phase power must connect into fuse holder terminals

F1, F2, and F3. Ground must attach to the green/yellow

terminal. All holes drilled through the control box must be

through the bottom of the box, Figure 21.

8. Route all field installed wires so that separation is

maintained between line voltage wires and low voltage

class II wiring. Electrical prints included in the control box

supersede any prints included in this owners manual on

Pages 28-35. Always check parts or control box for prints.

9. Separate 110VAC is required for the power of the

Thermal Air Seal blower, E-Vac or Virtual Vision junction

box.

10. Option provided for Step-Down Transformer to power the

Thermal Air Seal junction box.

ELECTRICAL INSTALLATION

When working with electrical or electronic controls, make sure

that the power source has been locked out and tagged according

to OSHA regulations and approved local electrical codes.

WARNING!!!

!

A qualified electrician should install the wiring in accordance with

local and national electrical codes. Use lockout and tagout

procedures to avoid injury.

IMPORTANT!!!

When drilling holes in the box, DO NOT turn control box upside

down or go too deeply into the box. Damage or debris may fall

into electrical components causing failure or severe equipment

damage.

CAUTION !!!

!

To reduce risk of injury or death, an earth ground connection

MUST BE made to the green/yellow control box ground terminal.

If metal conduit is used as the ground connector, an N.E.C.

approved ground bushing and green/yellow wire MUST BE

properly attached to the conduit for connection to the ground

terminal.

IMPORTANT!!!

In freezer and cooler applications where a conduit passes from a

warm to cold temperature zone, the conduit must be plugged with

epoxy. This will help prevent condensation from forming in the

conduit. For more information, see Section 300-7a of the National

Electric Code.

IMPORTANT!!!

FIGURE 20 - CONTROL BOX

54”

Conduit Bracket

Control Box Cable

Step Down

Transformer

Thermal Air

Seal, E-Vac or

Virtual Vision

Junction Box

Loading...

Loading...