5-4

REASSEMBLY PROCEDURES

0

PRECAUTIONS FOR REASSEMBLY

1)

Clean parts throughly before reassembly.

2)Scrape off all carbon deposits from cylinder head, piston top and piston ring grooves.

3)Check lip of oil seals. Replace

oil

seal

if

the lip

is

damaged.

Apply

oil

to the lip before reassembly.

4)Replace all the gaskets with new ones.

5)Replace keys, pins, bolts, nuts, etc.,

if

necessary.

6)Torque bolts and

nuts

to specification referring to the

“TORQUE SPECIFICATIONS”.

7)Apply

oil

to rotating and sliding portions.

8)Check and adjust clearances

and

end plays where specified

in

this manual.

Pay most attention to cleanliness

of

piston, cylinder, crankshaft, connecting rod

and

bearings.

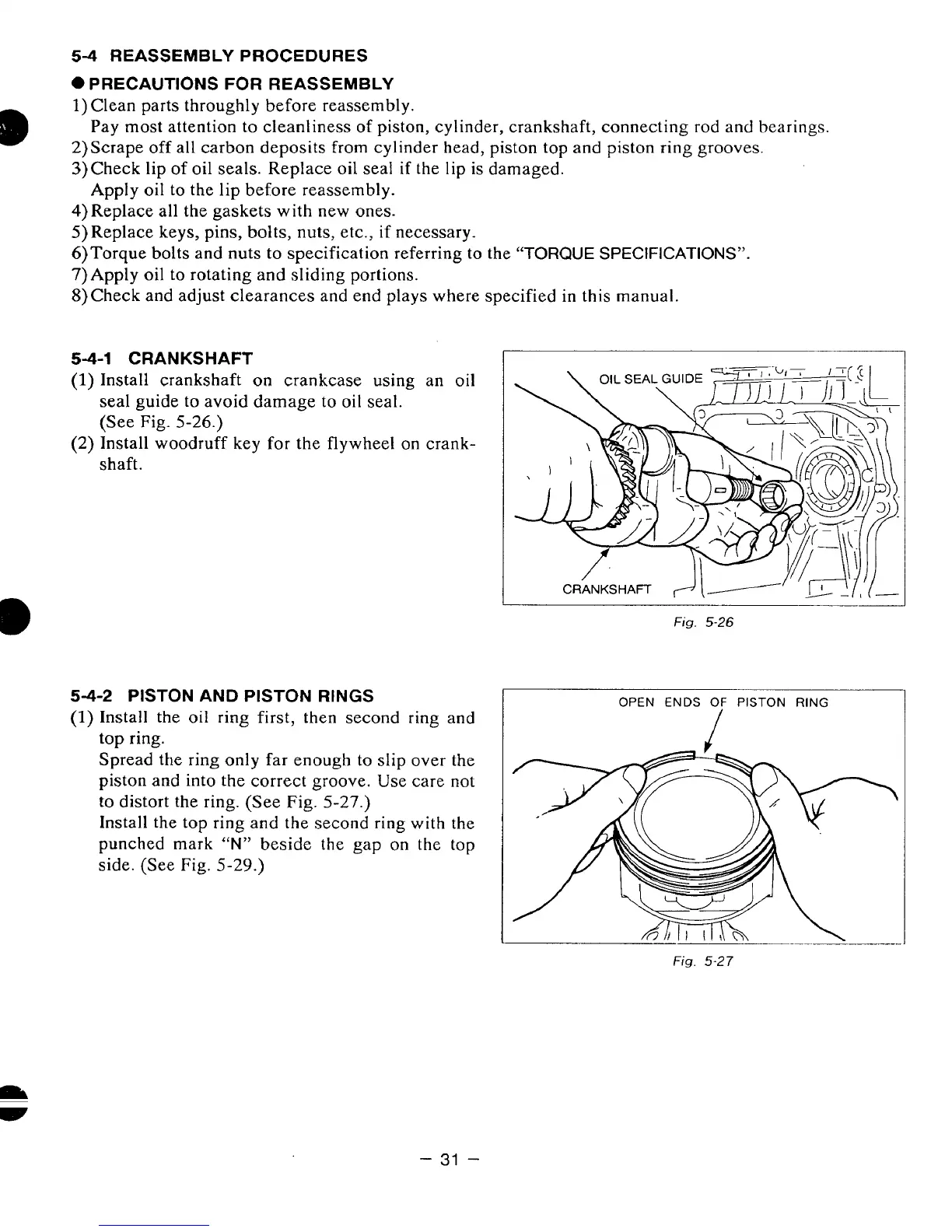

54-1

CRANKSHAFT

(1)

Install crankshaft

on

crankcase using an oil

seal guide to avoid damage to oil seal.

(See Fig.

5-26.)

shaft.

(2)

Install woodruff key

for

the

flywheel

on

crank-

Fig.

5-26

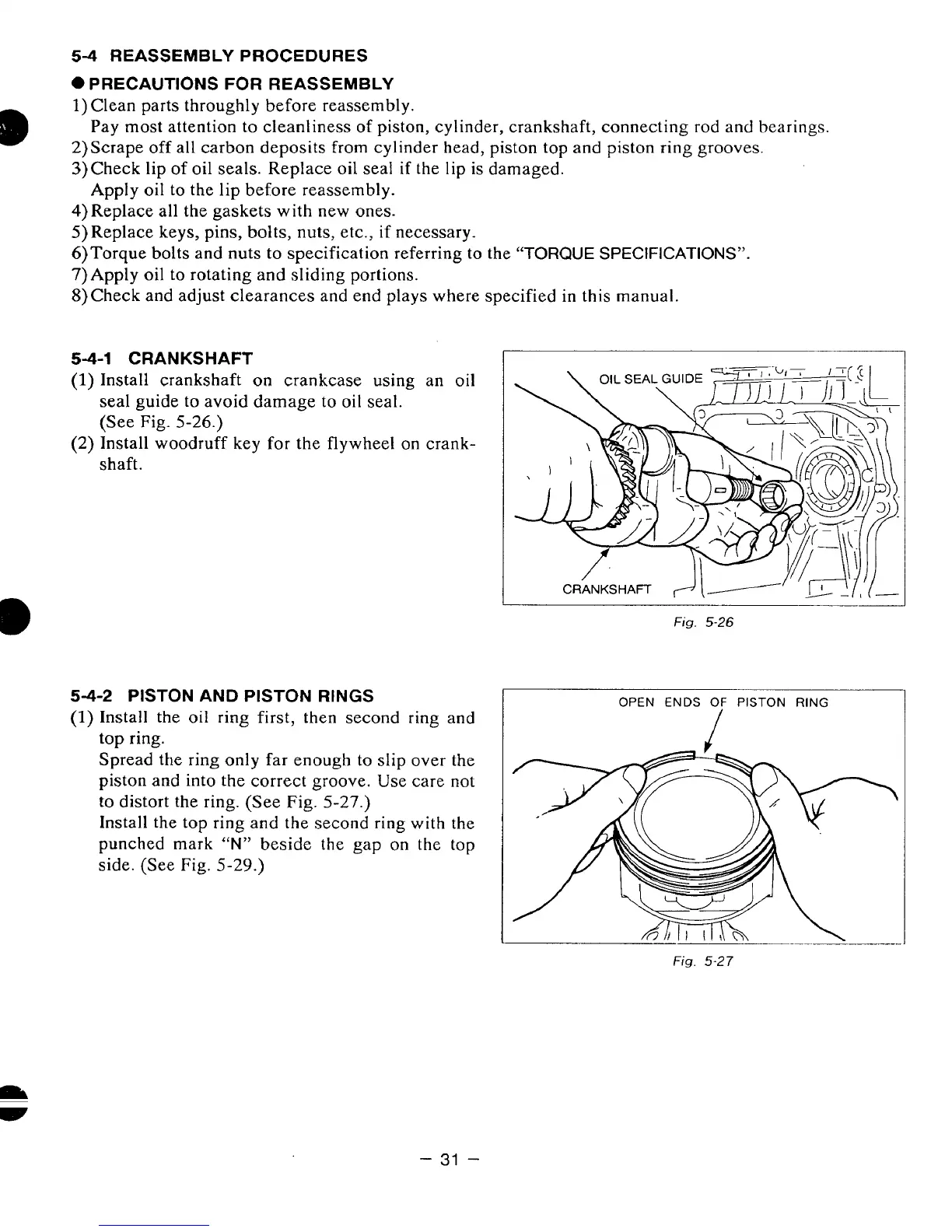

5-4-2

PISTON AND PISTON RINGS

(1)

Install the

oil

ring

first, then second ring and

top

ring.

Spread

the

ring

only

far enough to slip over the

piston and into the correct groove. Use care not

to

distort the ring. (See Fig.

5-27.)

Install the top ring and the second ring with the

punched

mark

“N”

beside the gap

on

the top

side. (See Fig.

5-29.)

OPEN ENDS

OF

PISTON

RING

I

Fig.

5-27

-

31

-

Loading...

Loading...