Heating engineer

18

3

2.5.1 Axial gas unit heaters

For axial gas unit heaters the following support brackets

are available as optional:

▶

O19800020 revolving wall support bracket (M20, M25

models)

▶

O19800024 revolving wall support bracket (M30 mod-

el)

▶

OKMN000 swivel bracket (models M35, M36, M40)

▶

O19800026 revolving wall support bracket (M50 mod-

el)

▶

O19800028 revolving wall support bracket (M60 mod-

el)

▶

OSTF009 support bracket 1,4 m length

▶

Tubular bracket OSTF005

All support brackets are supplied with bolts and the rear

support plate.

For mounting instructions of the brackets, refer to the rel-

evant instruction sheets.

2.5.2 Centrifugal gas unit heaters

For centrifugal gas unit heaters, the following mounting

brackets are available as optional:

▶

OSTF009 support bracket 1,4 m length

All support brackets are supplied with bolts and the rear

support plate.

For mounting instructions of the brackets, refer to the rel-

evant instruction sheets.

3 HEATING ENGINEER

3.1 WARNINGS

3.1.1 General warnings

Read the warnings in Chapter III.1

p. 4

, pro-

viding important information on regulations and

on safety.

Compliance with installation standards

Installation must comply with applicable regula-

tions in force, based on the installation Country

and site, in matters of safety, design, implementa-

tion and maintenance of:

heating systems

gas systems

ue gas exhaust

ue gas condensate discharge

Installation must also comply with the manufactur-

er's provisions.

3.2 FUEL GAS SUPPLY

3.2.1 Gas connection

▶

1/2" M (models M20, M25, M30, M35, M36, M40)

▶

3/4" M (M50, M60 models)

on the rear, to the left (see dimensional diagrams,

Paragraph 1.2

p.8

).

▶

Install an anti-vibration connection between the ap-

pliance and the gas piping.

3.2.2 Mandatory shut-o valve

▶

Provide a gas shut-o valve (manual) on the gas supply

line, next to the appliance, to isolate it when required.

▶

Provide a three-piece pipe union.

▶

Perform connection in compliance with applicable

regulations.

3.2.3 Gas pipes sizing

The gas pipes must not cause excessive pressure drops

and, consequently, insucient gas pressure for the

appliance.

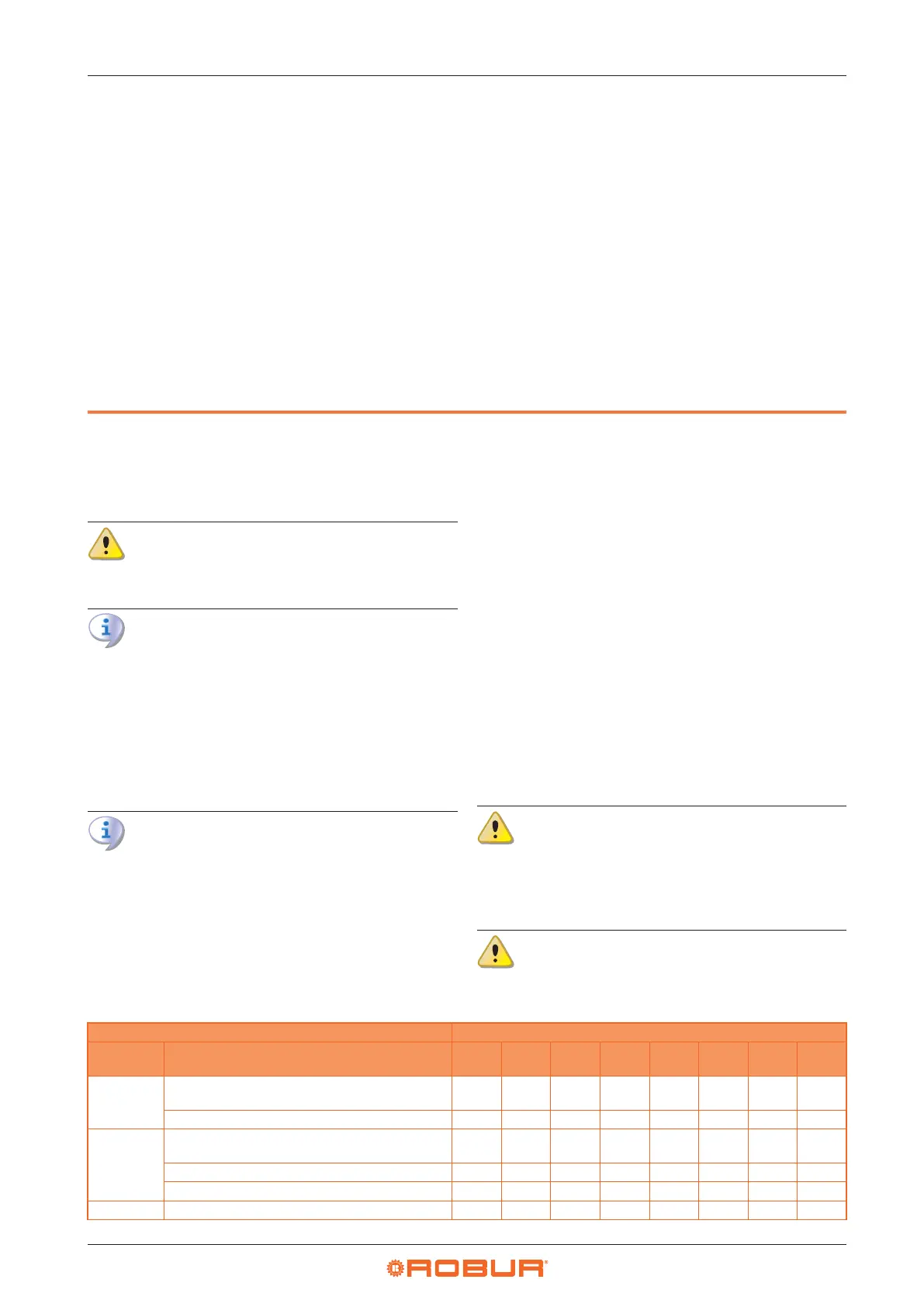

3.2.4 Supply gas pressure

This appliance is equipped for a maximum gas

supply pressure of 50 mbar.

The appliance's gas supply pressure, both static and dy-

namic, must comply with Table 3.1

p.18

, with tolerance

± 15%.

Non compliant gas pressure (Table 3.1

p. 18

)

may damage the appliance and be hazardous.

Table3.1 Network gas pressure

Gas supply pressure [mbar]

Product

category

Countries of destination G20 G25 G25.1 G25.3 G2.350 G27 G30 G31

II

2H3B/P

AL, BG, CH, CY, CZ, DK, EE, FI, GR, HR, IT, LT, LV, MK, NO,

RO, SE, SI, SK, TR

20 30 30

AT, CH 20 50 50

II

2H3P

AL, BG, CH, CZ, ES, GB, GR, HR, IE, IT, LT, LV, MK, PT, SI,

SK, TR

20 37

RO 20 30

AT 20 50

II

2ELL3B/P

DE 20 20 50 50

Loading...

Loading...