Heating engineer

22

3

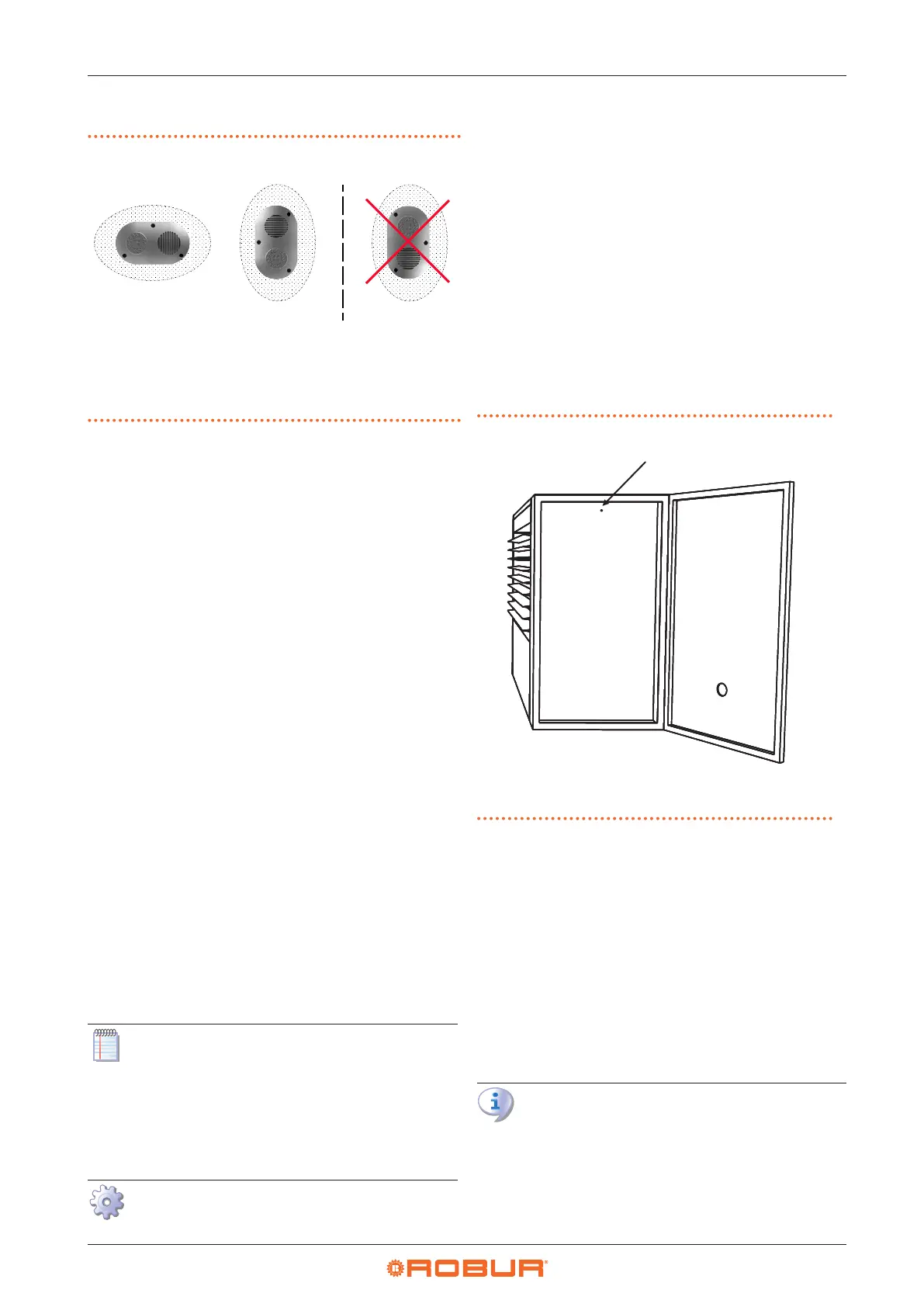

details given in Figure 3.8

p.22

.

Figure3.8 Wall terminal position

IN combustion air intake

OUT ue gas exhaust

A recommended posi-

tion (OK)

B allowed position (OK)

C position NOT allowed

(NO)

IN

OUT

IN

OUT

IN

OU

3.3.5 Example of calculation

If a M35 unit equipped with a 50 mm high ue diaphragm

is to be installed, the air/ue system will be realized in the

following way:

▶

3 metres of Ø 110 ue pipe

▶

2 90° Ø 110 elbows attached to the ue pipe

▶

2 metres of Ø 130 air pipe

It is then possible to proceed with the verication calcu-

lation, remembering that the maximum permissible pres-

sure drop is 12 Pa (see Table 3.2

p.21

).

Q.ty Resistance

▶

Ø 110 ue pipe

3 m x 1,7 Pa = 5,1 Pa

▶

90° curve

2 x 3,7 Pa = 7,4 Pa

▶

Ø 130 air pipe

2 m x 0,8 Pa = 1,6 Pa

Total pressure drop = 14,1 Pa

Total pressure drop of the piping system is greater than

the maximum allowed pressure drop (12 Pa), therefore

the installation is not allowed.

The installation can be done if one of the following steps

is taken:

▶

t a ue diaphragm 40 mm high

▶

use the Ø 130 ue pipe

▶

reduce the length in metres of the ue duct

In this case the ue diaphragm cannot be removed, as this

will result in the total pressure drop of the ue system to

be lower than the minimum pressure drop allowed for the

unit.

If the total length of the pipe system exceeds 16

metres, it is advisable to contact the technical ser-

vice Robur by telephone.

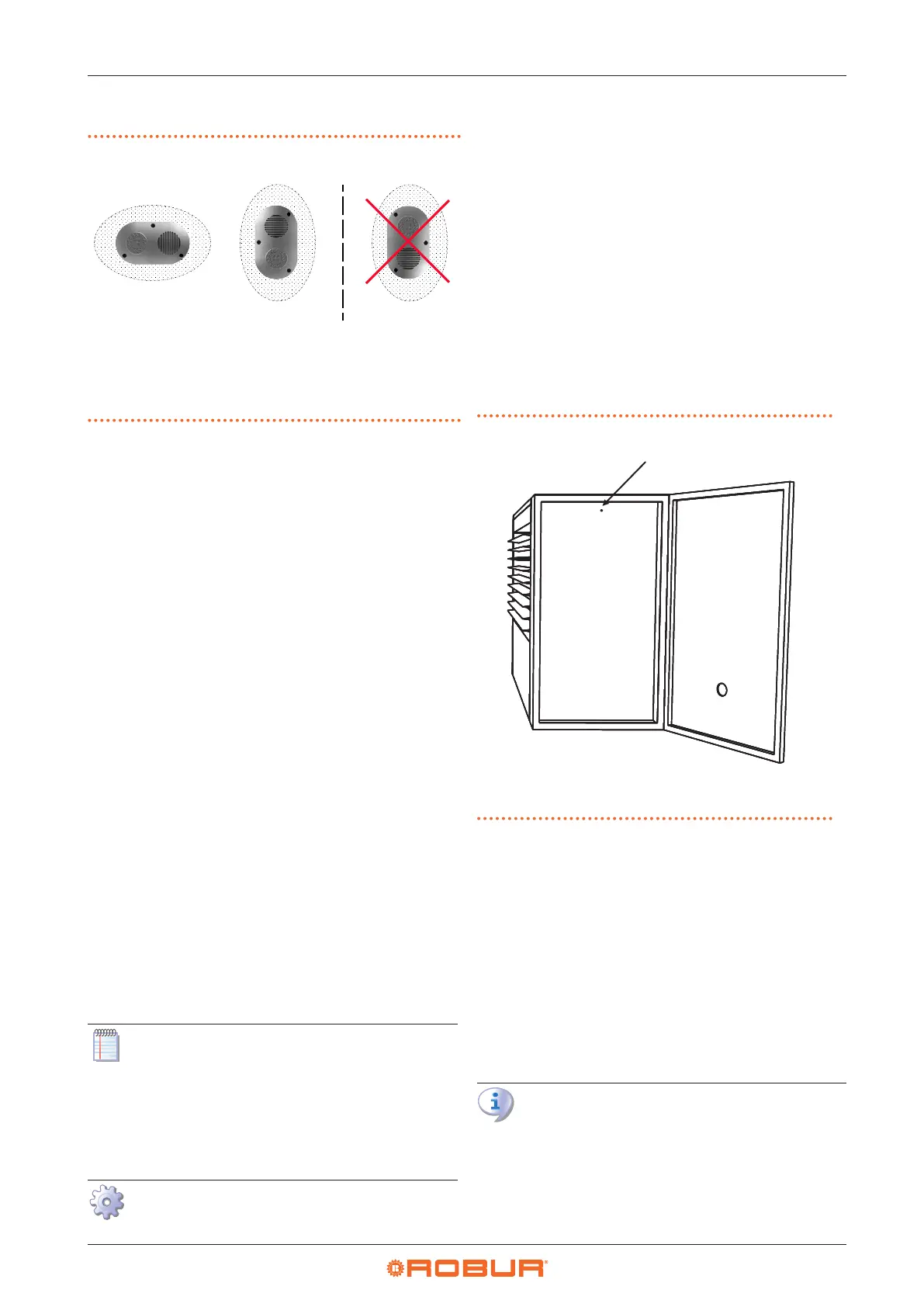

3.3.6 Installing the ue diaphragm

One or more smoke diaphragm is supplied with the M se-

ries generators.

How to mount the smoke diaphragm

1. Ensure the appliance is not live.

2. Open the electrical panel door.

3. Loosen the screw which secures the cover (see Figure

3.9

p.22

).

4. Remove the cover.

5. Undo the two lower screws which secure the ue fan

and loosen the two upper screws.

6. Insert the ue diaphragm between the ue outlet

ange and the ue fan ange, so that the holes in the

diaphragm are turned downwards.

7. Make the holes in the diaphragm match with the low-

er holes.

8. Tighten again the lower and upper screws that secure

the ue fan.

9. Replace the electrical panel cover and tighten the x-

ing screw.

Figure3.9 Assembly of ue diaphragm

1 Cover locking screw

3.4 AIR DUCTING

Only models equipped with a centrifugal fan

(M gas unit heater C series) can be combined with air

ducting systems, which can be positioned both on the

air intake (with or without mixing chambers) and on the

delivery.

For this purpose, the delivery outlet of the M gas unit heater

C gas unit heaters is provided with xing anges for the

delivery air ducting.

Refer to the Paragraph 2.4.2.1

p. 17

for the dimensions

of the ange connection.

In order to avoid vibrations (possible source of

noise and mechanical failures), it is advisable to

install anti-vibration connections, easily removable

for maintenance operation, at the connection be-

tween the gas unit heater and the air duct.

Set up the air ducting using a traditional suciently

Loading...

Loading...