Normal operation

Installation, use and maintenance manual – Supercromo

19

6

3001 3002

Nozzle

Diame-

ter (Ø)

G20 mm 1,45/1,70

G25 mm 1.75/1,80

G30 mm 0.85/0,95

G31 mm 0.85/0,95

Code

G20 - 53

G25 - 54

G30 - 50

G31 - 50

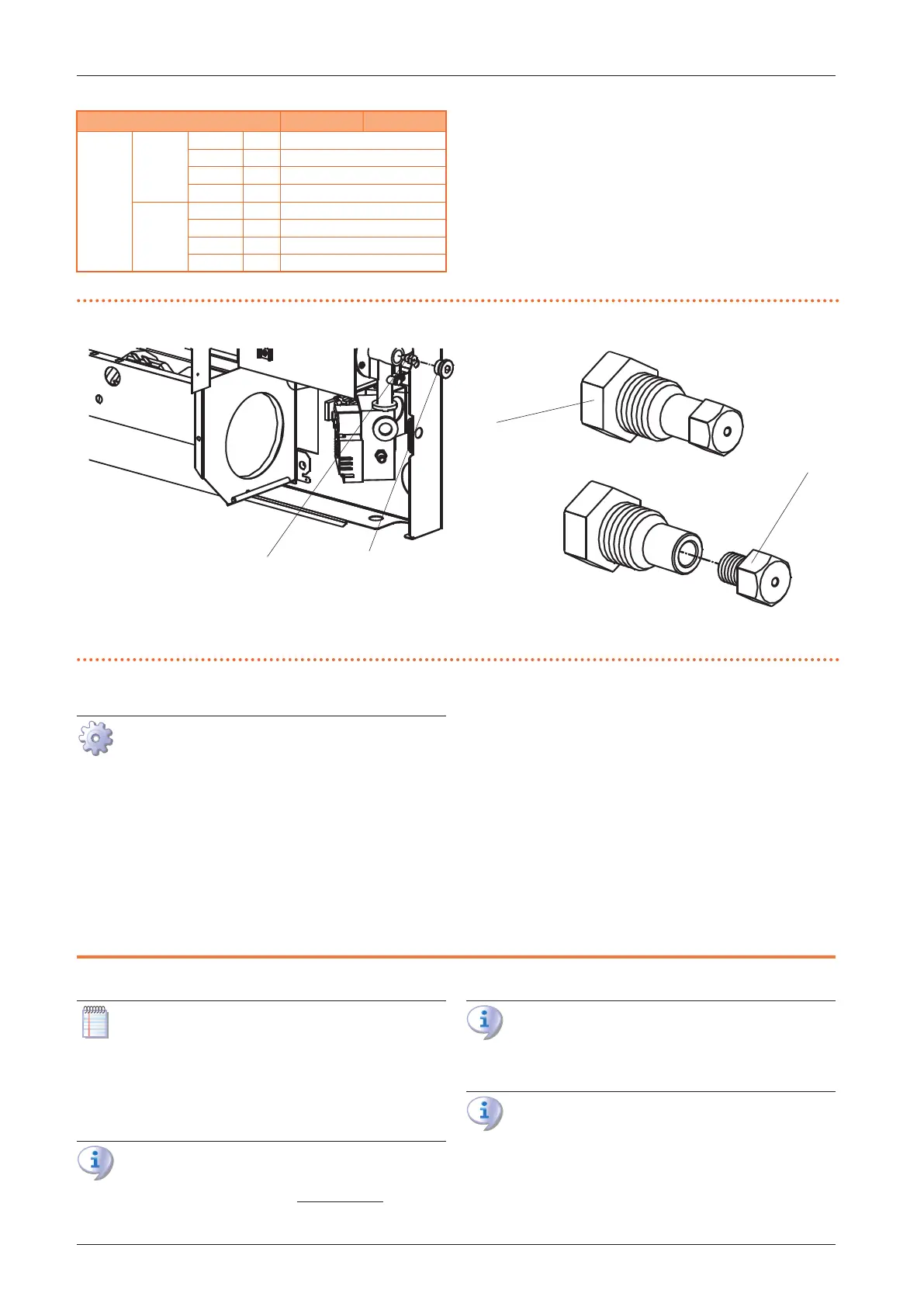

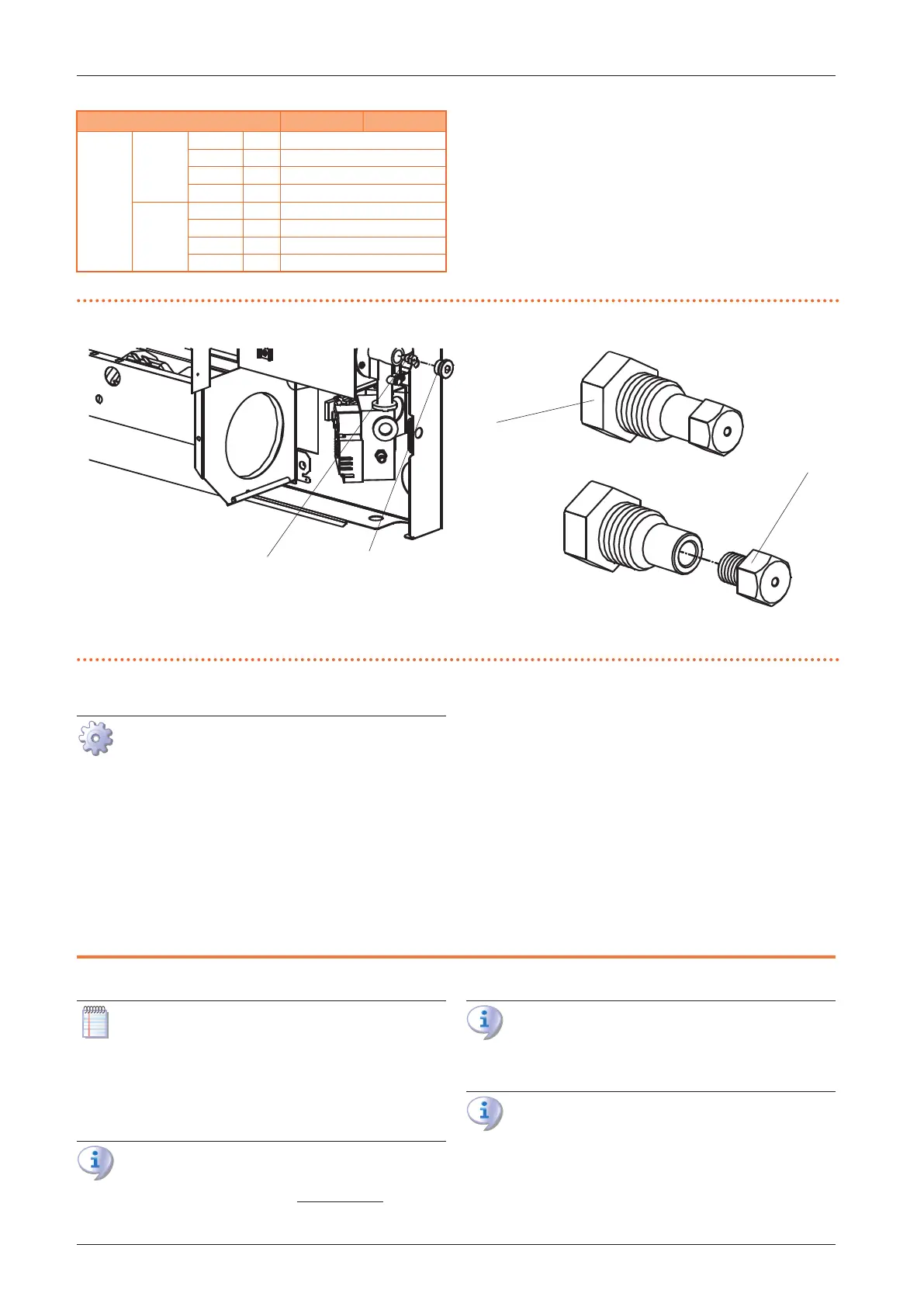

Figure5.2 Detail of burner assembly

A Nozzle holder. B Cap

5.3.2 Conversion from LPG to natural gas

Figure 5.2

p.19

1. Cut o electric power and gas supply.

2. Remove the casing from the frame and disconnect the

casing grounding cable.

3. Unscrew the B plug with a no. 19 wrench.

4. Using a no.10 socket wrench introduced in the open-

ing, unscrew the nozzle holder A.

5. Unscrew the calibrated nozzle C from the nozzle hold-

er A and replace it (Table 5.2

p.18

).

6. Screw the nozzle support and nozzle assembly back

on to the burner.

7. Reassemble the plug B.

8. Turn on the gas-red convector and check the gas

tightness of plug B.

9. Check the gas pressure at the burner as described in

Paragraph 5.2.1

p.17

.

10. Remove the "LPG" adhesive label and replace it with

the "NATURAL GAS" adhesive label.

11. Connect the grounding cable of the casing and reas-

semble the casing.

6 NORMAL OPERATION

This section is for the end user.

The operation of the Supercromo gas-red heaters is con-

trolled by the supplied control panel.

6.1 WARNINGS

General warnings

Prior to using the appliance carefully read the warn-

ings in Chapter III.1

p. 4

, providing important

information on regulations and on safety.

First startup by TAC

First start-up may exclusively be carried out by a

Robur TAC (Chapter 7

p.23

).

Never power the appliance o while it is run-

ning

NEVER power the appliance o while it is running

(except in the event of danger, Chapter III.1

p. 4

),

since the appliance or system might be damaged.

Loading...

Loading...