Maintenance

Installation, use and maintenance manual – Supercromo

23

7

Case 2: the status of the programmer clock output is

"OFF" (red LED o)

1. Press the MANUAL button to move the indicator from

"AUTO" to "ON", the programmable timer output will

change to the state "ON" and the red LED will light up;

this way, the set programs will be skipped.

2. To reactivate the running of the set programs, press the

MANUAL button again, the indicator will move from

"ON" to "AUTO" but the output of the programmable

timer will continue to stay "ON" (red LED on). The pro-

grammable timer will resume its automatic operation

when the next program will switch to the status "OFF"

(i.e. until the status of the request is changed).

7 MAINTENANCE

7.1 WARNINGS

Correct maintenance prevents problems, assures

eciency and keeps running costs low.

Any operation on internal components may exclu-

sively be performed by the TAC.

Before performing any operation, switch o the

appliance by means of the control device and wait

for the end of the shutdown cycle, then disconnect

power and gas supply, by acting on the electrical

disconnector and gas valve.

The eciency checks and every other "check and

maintenance operation" must be performed with

a frequency according to current regulations or,

if more restrictive, according to the provisions set

forth by the manufacturer, installer or TAC.

Responsibility for eciency checks, to be carried

out for the aims of restricting energy consumption,

lies with the system manager.

7.2 CLEANING AND MAINTENANCE

The only operation required by this kind of gas-red con-

vector is the cleaning of the outer casing (which must al-

ways be carried out with the appliance cold and without

the use of solvents) and the periodic removal of any dust

that may accumulate on the heat exchanger and the fan.

It is recommended to have a periodic (annual) check and

cleaning of the gas-red convector by contacting a TAC.

With regard to periodic maintenance of the gas-red con-

vector, follow the regulations in force.

7.3 SAFETY DEVICES

Electricity outage

The gas-red convector is switched o by closing

the gas valve. When the power supply is restored,

the gas-red convector will automatically restart.

Gas failure or other faults that causes the ame

to extinguish

The gas-red convector will automatically attempt

to restart for a period of 10 seconds, after which, if

the attempt fails, the control unit will lock out the

gas-red convector and stop the blower (red signal

light lit on the control panel).

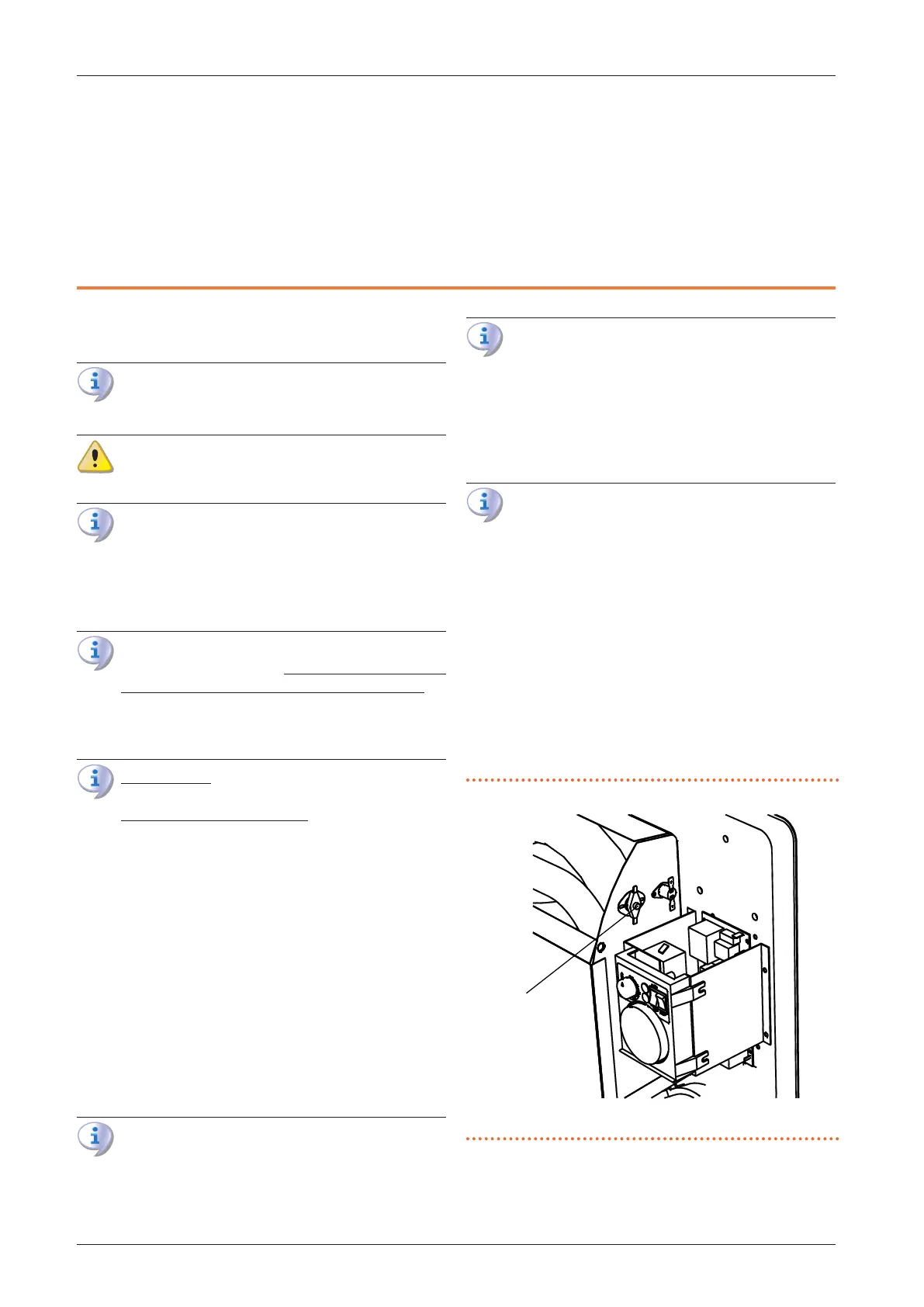

Overheating

If during operation the upper or lower grille is

partially obstructed or the fan stops, causing the

gas-red convector to overheat, the limit thermo-

stat trips, cutting o the power supply to the gas

valve, interrupting the ow of gas to the burner. To

restore operation, wait about ten minutes for the

temperature to drop, disconnect the gas-red con-

vector from the power supply, remove the casing

and reset the limit thermostat by pressing the reset

button located on the limit thermostat itself (detail

A in Figure 7.1

p.23

). If the problem is repeated

within a short period of time, TAC must be called in

to check the causes of overheating.

Figure7.1 Limit thermostat

A Limit thermostat

7.4 ANY MALFUNCTIONS OF OPERATION

Before taking any particular measures, always check that:

Loading...

Loading...