Heating engineer

12

3

I

3P

NO 30

I

3B/P

MT, CY

30 30

I

3B

30

The appliance gas supply pressure, both static and dynamic, must comply with the values in the Table, with a tolerance of ± 15%.

3.3.5 Vertical pipes and condensate

▶

Vertical gas pipes must be tted with siphon and dis-

charge of the condensate that may form inside the

pipe.

▶

If needed, insulate the piping.

3.3.6 LPG pressure reducers

With LPG the following must be installed:

▶

A rst stage pressure reducer, close to the liquid gas

tank.

▶

A second stage pressure reducer, close to the appli-

ance.

Pressure reducers must always be installed outside

the building.

3.4 COMBUSTION PRODUCTS EXHAUST

Compliance with standards

The appliance is approved for connection to a

combustion products exhaust duct for the types

shown in Table 1.1

p.9

.

3.4.1 Flue gas exhaust and combustion air

intake connection

▶

Ø 50 mm on the rear (Figure 1.1

p.8

)

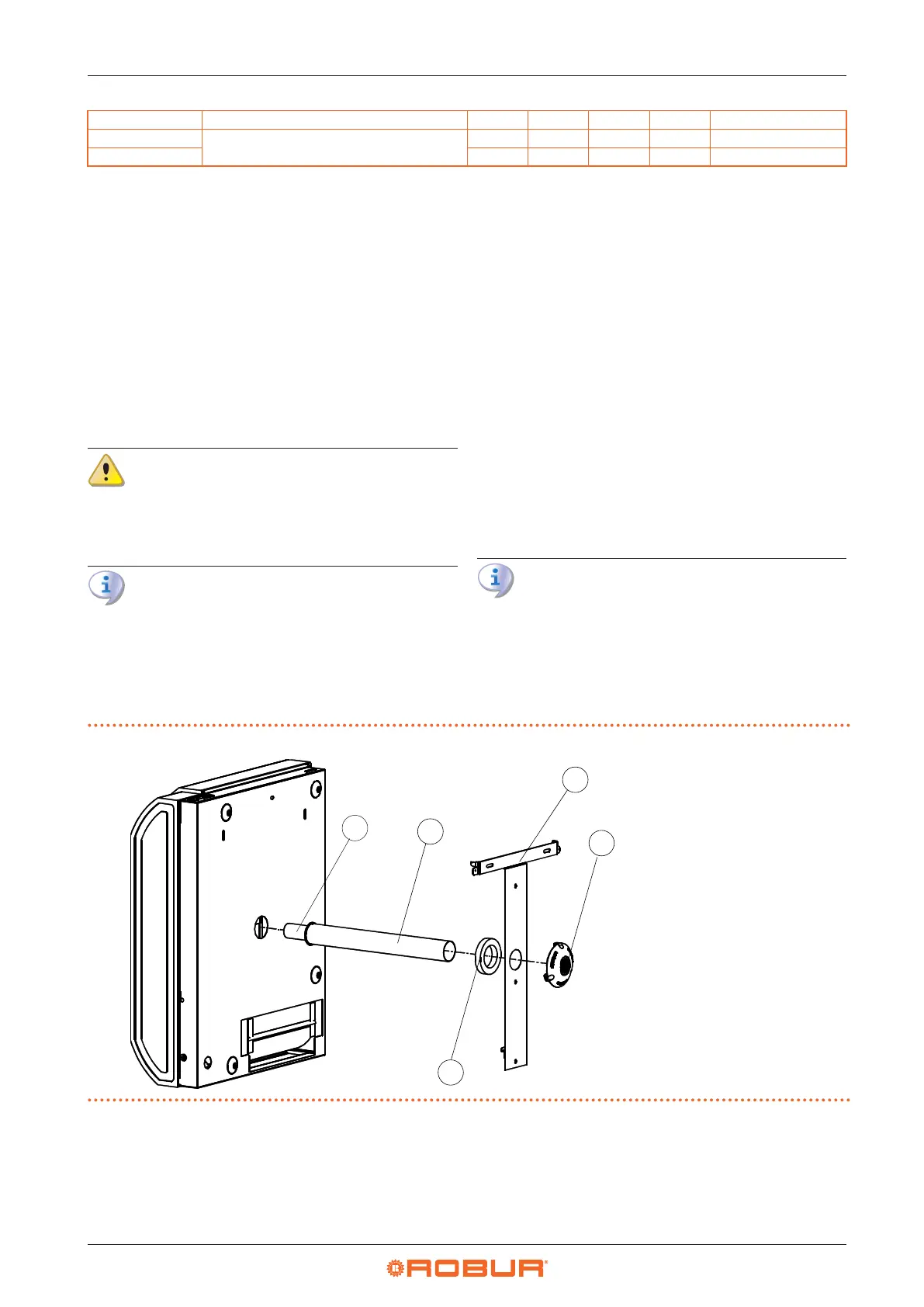

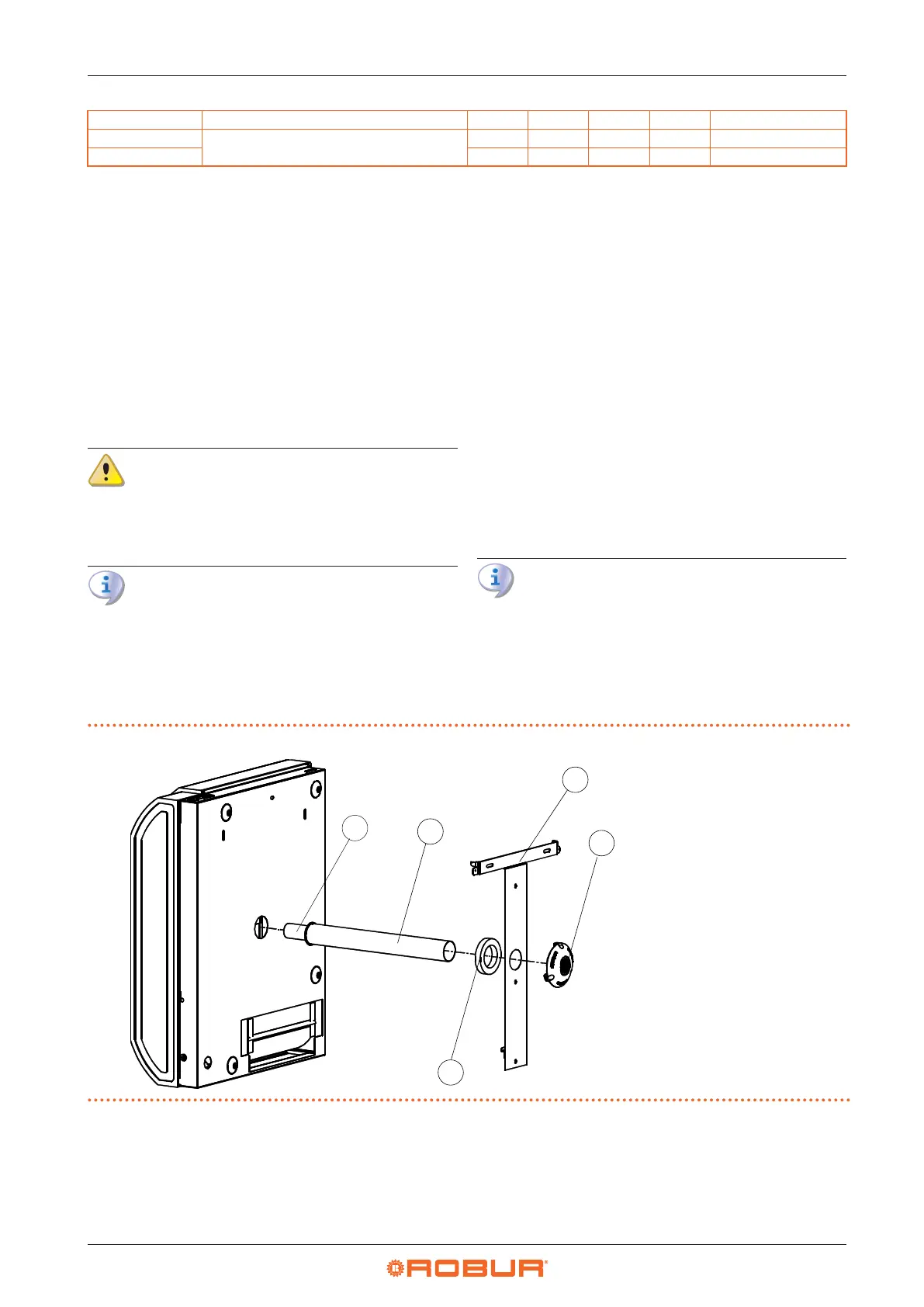

3.4.2 Installation types

The ue gas exhaust/combustion air intake of the

Supercromo gas-red convectors can be realised in one of

the following ways:

▶

With coaxial pipes with outlet on the installation

wall (maximum pipe length: 1 metre) (see Figure

3.2

p.12

).

▶

With coaxial pipes with 90° outlet (max pipe length: 1

metre) (see Figure 3.3

p.13

). In this case, it is neces-

sary to use the 90° casing for coaxial pipes, available as

OCFF004 optional.

▶

With separate pipes (see Figure 3.4

p. 13

). In this

case, it is necessary to use the separate exhaust casing

available as OCFF002 optional.

Warnings

The installation of pipes with a vertical downward

outlet is prohibited (leads to recirculation of ue

gas with lock-out of the appliance).

It is forbidden to install coaxial pipes with a vertical

outlet upwards (due to rain, water, objects inltra-

tion with consequent lock out of the appliance).

Figure3.2 Installation with straight coaxial pipes

A Air pipe Ø 49 mm

B Flue gas pipe Ø 35 mm

C Adhesive gasket

D Support bracket

E Wall terminal Ø 35 mm

A

B

C

D

E

Loading...

Loading...