Heating engineer

Installation, use and maintenance manual – Supercromo

13

3

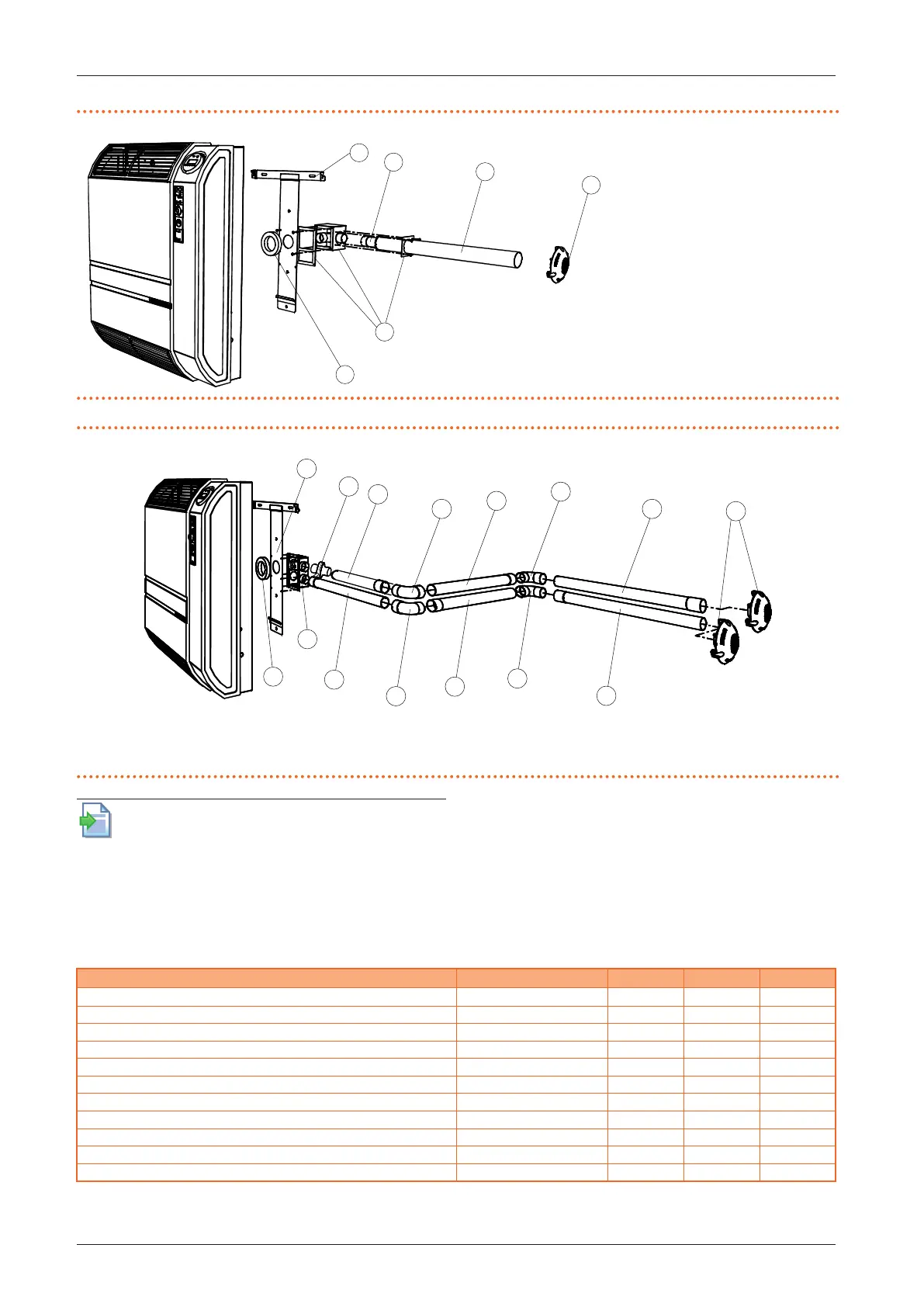

Figure3.3 Installation with coaxial pipes with 90° outlet

A Air pipe Ø 49 mm

B Flue gas pipe Ø 35 mm

C Adhesive gasket

D Support bracket

E Wall terminal Ø 35 mm

F 90° casing for coaxial exhaust

A

B

C

D

E

F

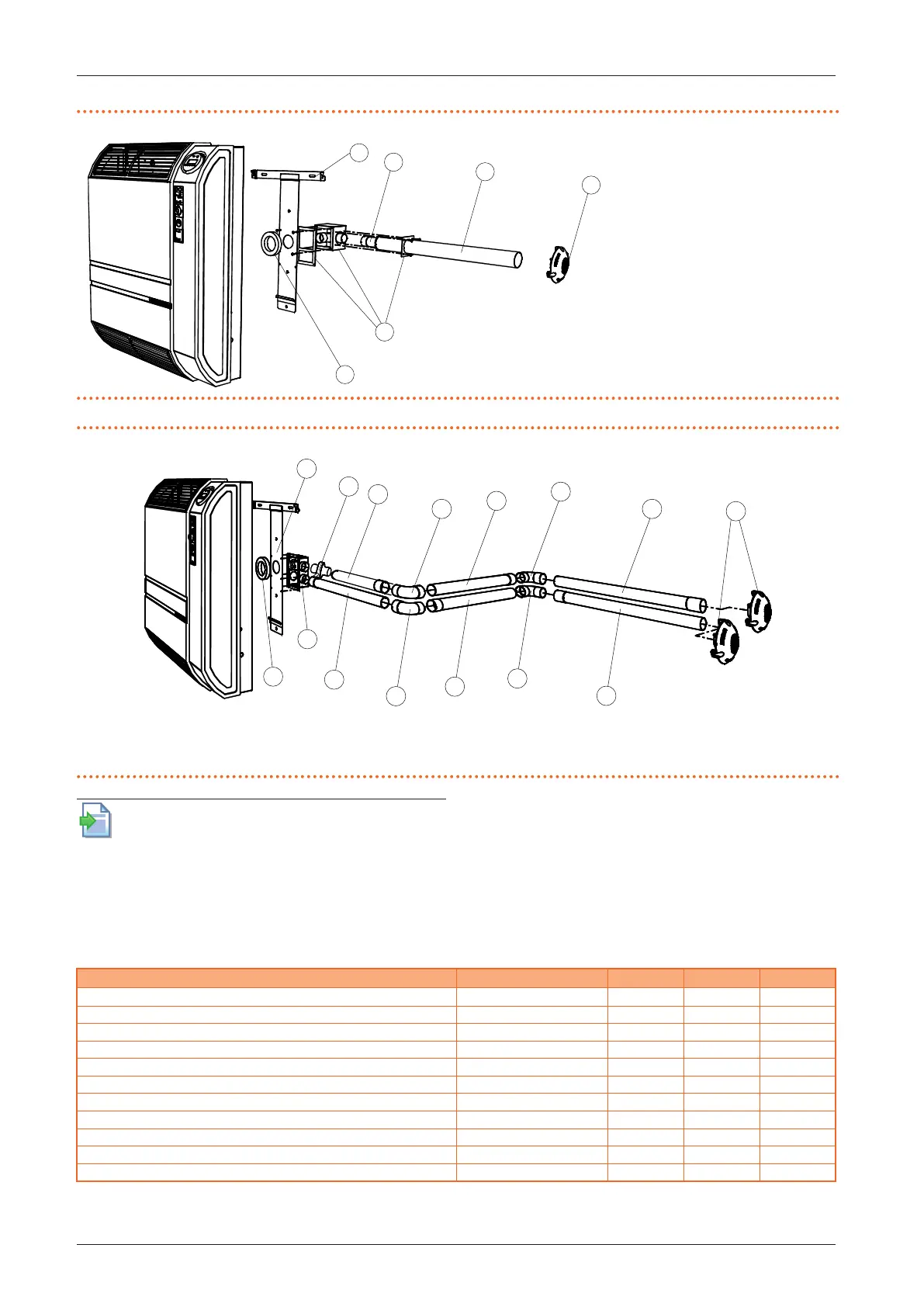

Figure3.4 Installation with wall separate ducts

A Air/ue gas pipe Ø 35 mm

B Elbow 90° M/F Ø 35 mm

C Adhesive gasket

D Support bracket

E Wall terminal Ø 35 mm

F 90° casing for separate exhaust

G Condensate discharge Ø 35 mm

D

A

B

A

A

A

A

B

B

E

F

C

G

For further information on the installation of the

ue gas exhaust/air intake duct, please refer to the

installation guide for the ue gas exhaust/air intake

ducts D-GPP001, available on the Robur website.

3.4.2.1 Installation with separate ducts

If the appliance is installed with separate pipes, suitable

pipes and components, available as optional, must be

used.

At the design stage, it must be veried that the sum of the

pressure drop of all components used does not exceed

the value of the available residual head (Table 3.2

p.13

).

Table3.2 Separate exhaust pressure drop table

Description Code 3001 3002

residual head Pa 25 25

Air pipe internal Ø 33 mm OPRL000 Pa/m 0,6 0,6

Horizontal ue gas pipe internal Ø 33 mm OPRL000 Pa/m 1,5 1,5

Vertical ue gas pipe internal Ø 33 mm OPRL000 Pa/m 0,2 0,2

90° elbow on air pipe OCRV000 Pa 0,6 0,6

90° elbow on ue gas pipe OCRV000 Pa 1,0 1,0

Casing complete with internal elbow for ue gas exhaust OCFF002 Pa 1,5 1,5

Casing without internal elbow for ue gas exhaust OCFF002 Pa 1,0 1,0

Roof terminal Ø 35 mm OTRM002 Pa 0,0 0,0

Wall terminal JTRM000B Pa 0,0 0,0

Condensate discharge Ø 35 mm OSCR003 Pa 0,0 0,0

If the ue gas pipe is longer than 1,5 metres, a condensate drain (available as OSCR003 optional) must be installed

Loading...

Loading...