Rockwell Automation Publication 750-UM002H-EN-P - February 2017 33

Safe Torque Off Option Module Operation Chapter 3

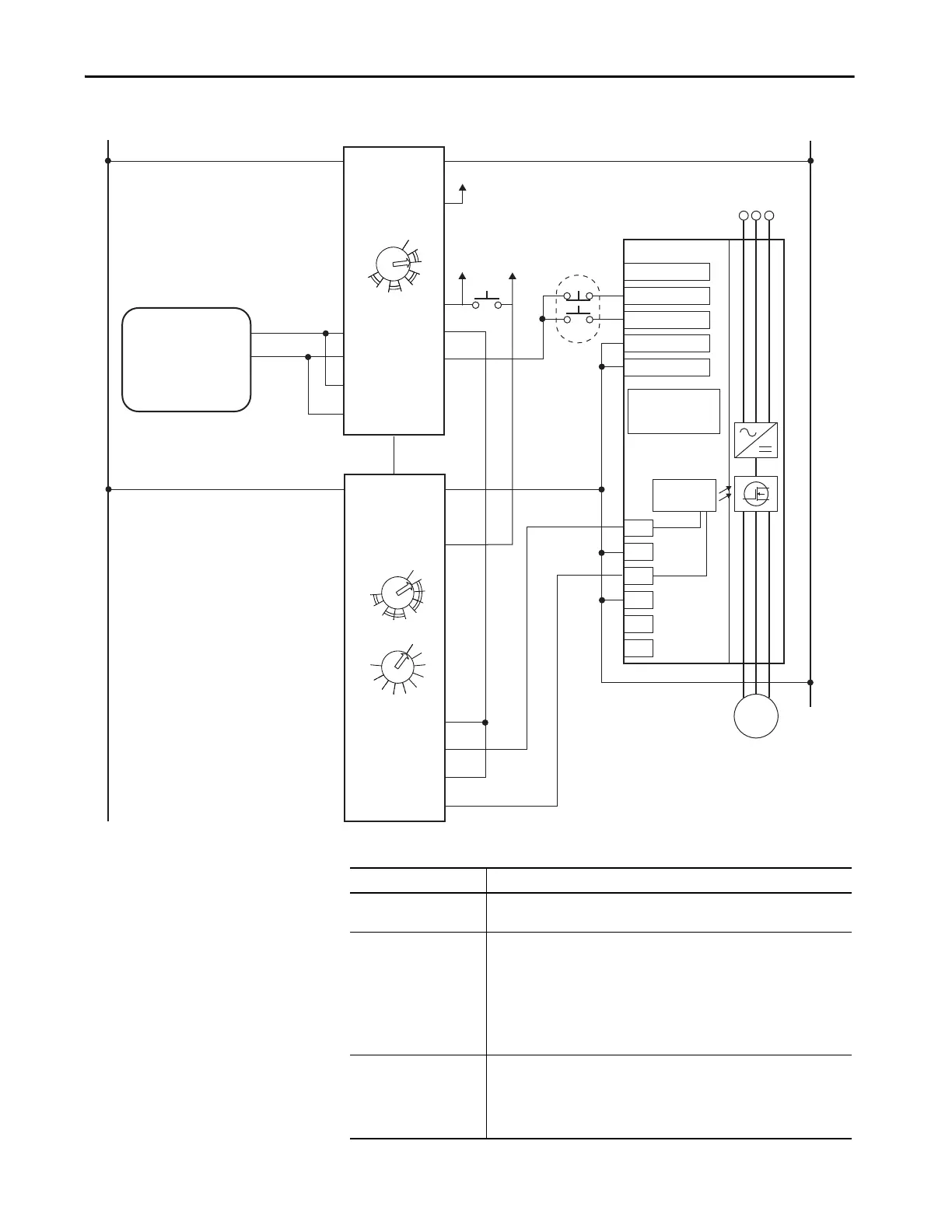

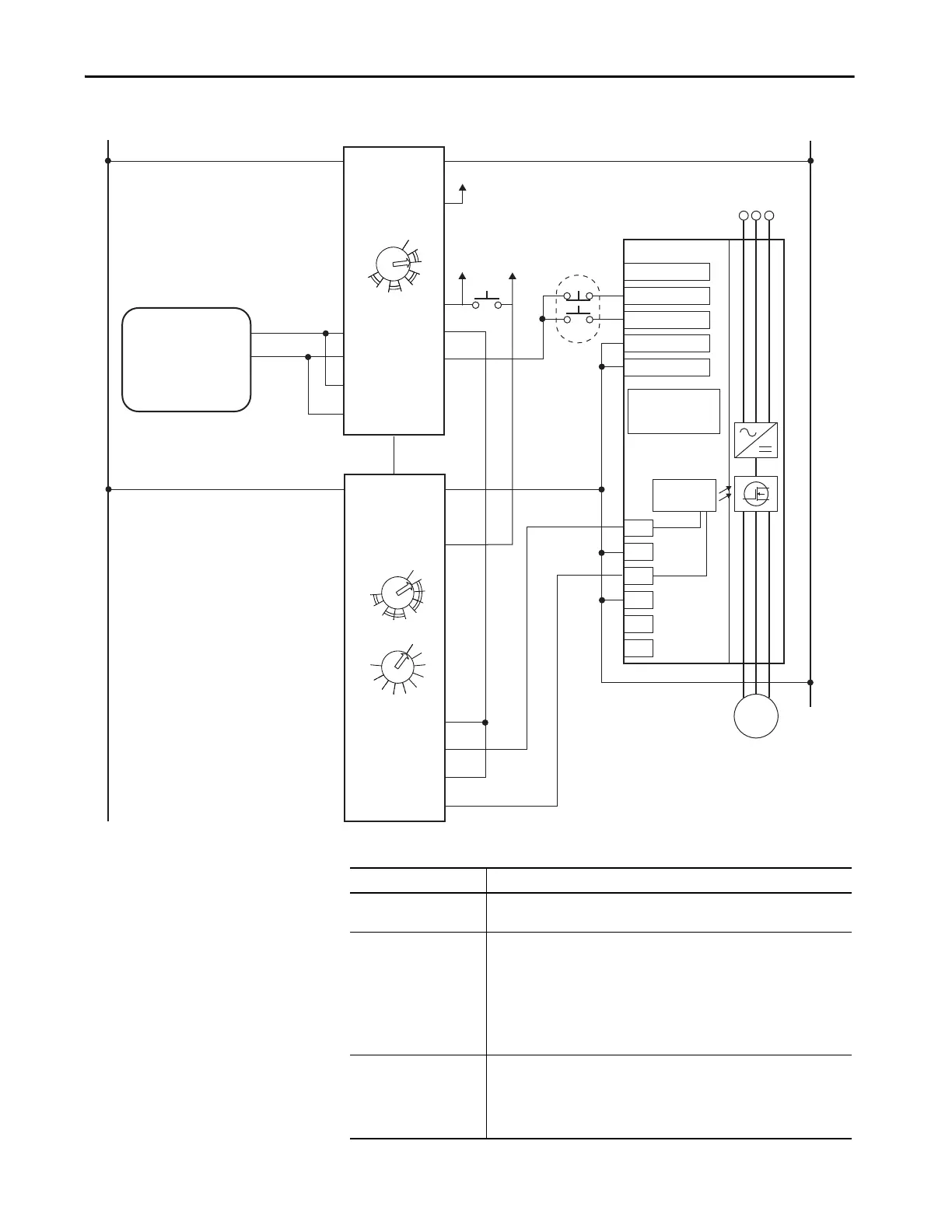

Figure 8 - Stop Category 1

Table 9 - Guardmaster DI and EMD Example Summary

SP+

SE+

Sd

SP–

SE–

Sd

A1

S11

S21

24V DC

0V DC COM

Gray

Pink

24V DC

DI

A2

S12

S22

S32

S42

13

14

23

24

0

1

2

3

4

56

7

8

LOGIC

A1

B1

A2

X32

37

38

47

48

17

18

27

28

1

2

3

4

5

6

7

8

RANGE

10

1

2

3

4

5

6

7

8

TIME

9

0

9

L12

L11

L11

EMD

Y32

S34

AC Line

Input Power

Motor

24V DC COM

START

STOP

PowerFlex 750-Series

Drive

Gate Control

Jumpers:

ENABLE Installed

SAFETY Removed

START/STOP COM

Guardmaster®

440R-D22R2

Dual-input Safety Relay

Guardmaster®

440R-EM4R2D

Expansion Module Delayed

SensaGuard

Interlock Switch

Reset

Aux

(PAC)

Aux

(PAC)

Aux

(PAC)

Attribute Description

Circuit status

Circuit is shown with guard door closed and system ready for normal drive

operation.

Operating principle

This is a dual-channel system with monitoring of the Safe Torque Off circuit and

drive. Opening the guard door switches the input circuits (S12, S22 and S32, S42) to

the Guardmaster monitoring safety relay. The output circuits (13, 14) issue a Stop

command to the drive and cause a controlled deceleration. After the programmed

delay, the timed output circuits (17, 18 and 27, 28) causes the Safe Torque Off

option module and the drive Enable circuit to trip. If the motor is rotating when the

trip occurs, it will coast to stop. To restart the drive, the Guardmaster safety relay

must first be reset followed by a valid start command to the drive.

Fault detection

A single fault detected on the Guardmaster safety input circuits results in the lock-

out of the system at the next operation and does not cause loss of the safety

function.

If the safety option module sticks ON, the motor stops on command due to the

enable input. The system cannot be reset when this fault condition exists.

Loading...

Loading...