Maintenance

Repair

MagneMover LITE Service Manual 119

Rockwell Automation Publication MMI-UM037A-EN-P - April 2020

Required Tools and Equipment

• Open-end wrench, 13 mm, thin.

• Socket wrench, 13 mm.

• Torque wrench (0.9–26 N•m [8–230 in•lb] range) with the following socket:

•13mm Hex.

• Loctite 290, Thread locker, Wicking Grade, Green.

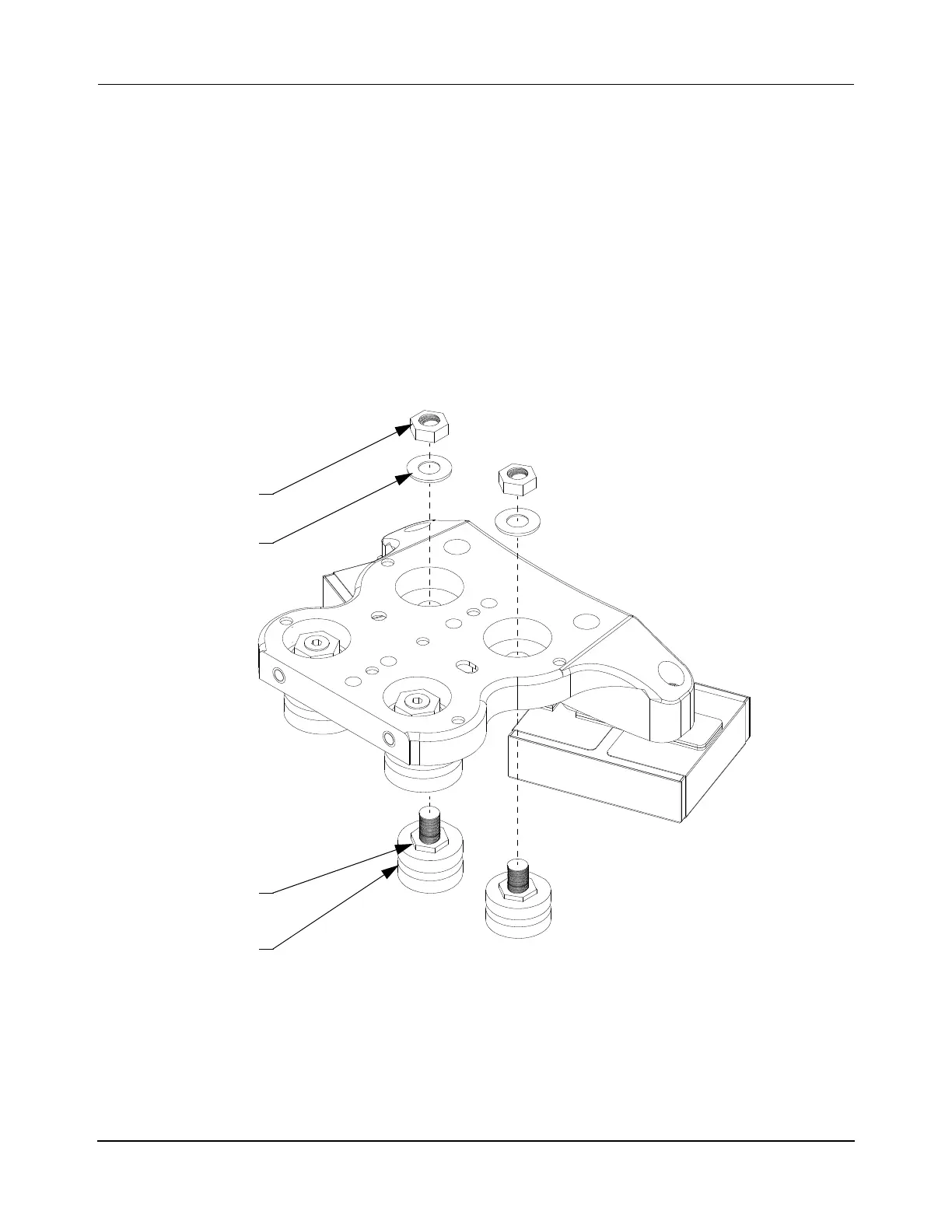

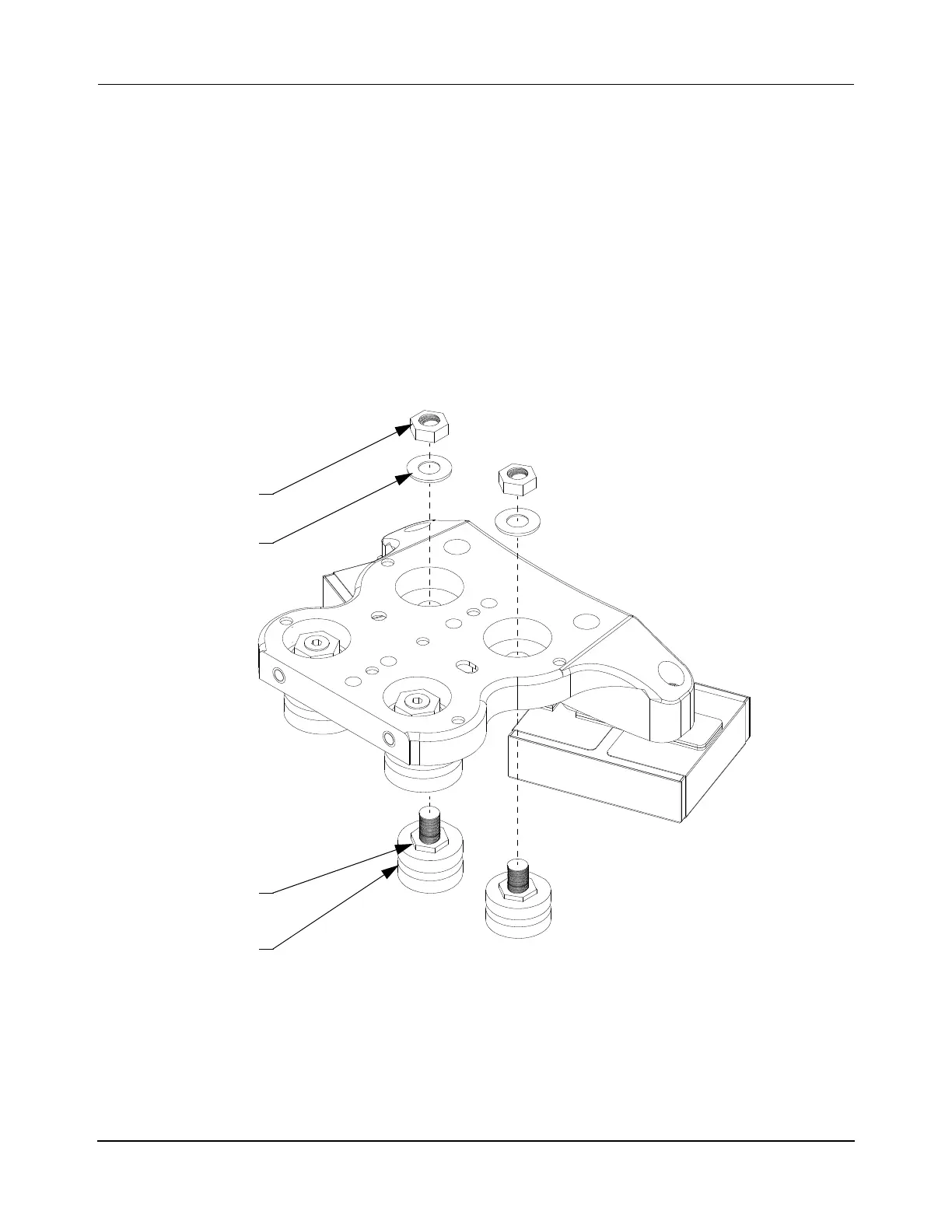

Replace Concentric Bearings

Figure 47 shows a dual array vehicle, however the same process is used for single array vehi-

cles.

Figure 47: Precision Rail Vehicle Concentric Bearings Disassembly/Assembly

1. Stop all motion on the path where the vehicle is located.

2. Remove the vehicle from the precision rail (see Replace Precision Rail Vehicles on

page 104).

Concentric

Washer

Bearing

Bearing Nut

(2X)

Top Nut

(2X)

(2X)

(2X)

Loading...

Loading...