Maintenance

Preventive Maintenance

50 MagneMotion

Rockwell Automation Publication MMI-UM037A-EN-P - April 2020

Concentric Bearings

Concentric bearings are not adjustable and must be tightened to 19 N•m [14 ft•lb] always.

Once tightened, apply Loctite 290 to the nuts on the top of the carriage and allow the Loctite

to cure for 3 hours at 22° C [72° F] before using the vehicle.

Eccentric Bearings

Eccentric bearings are adjustable, which enables them to be rotated either closer to or further

away from the rail. If the vehicle can be rocked from side to side or front to back, then there is

too much movement and one or both bearings must be readjusted and rotated closer to the rail

until the movement is eliminated. If the vehicle does not move easily along the rails, rotate

one or both bearings further away from the rails.

Adjustments that are made to the eccentric bearings on a vehicle, in relationship to the rail,

dictate how easily the vehicle moves along the rail. When the bearings are adjusted, the drag

force for the vehicle must not exceed the limits that are shown in Table 6. See the cut-away

view shown in Figure 14, to adjust the eccentric bearings on the vehicle. Make sure that the

center of the eccentric bearings is further apart than the center of the concentric bearings as

shown in Figure 15.

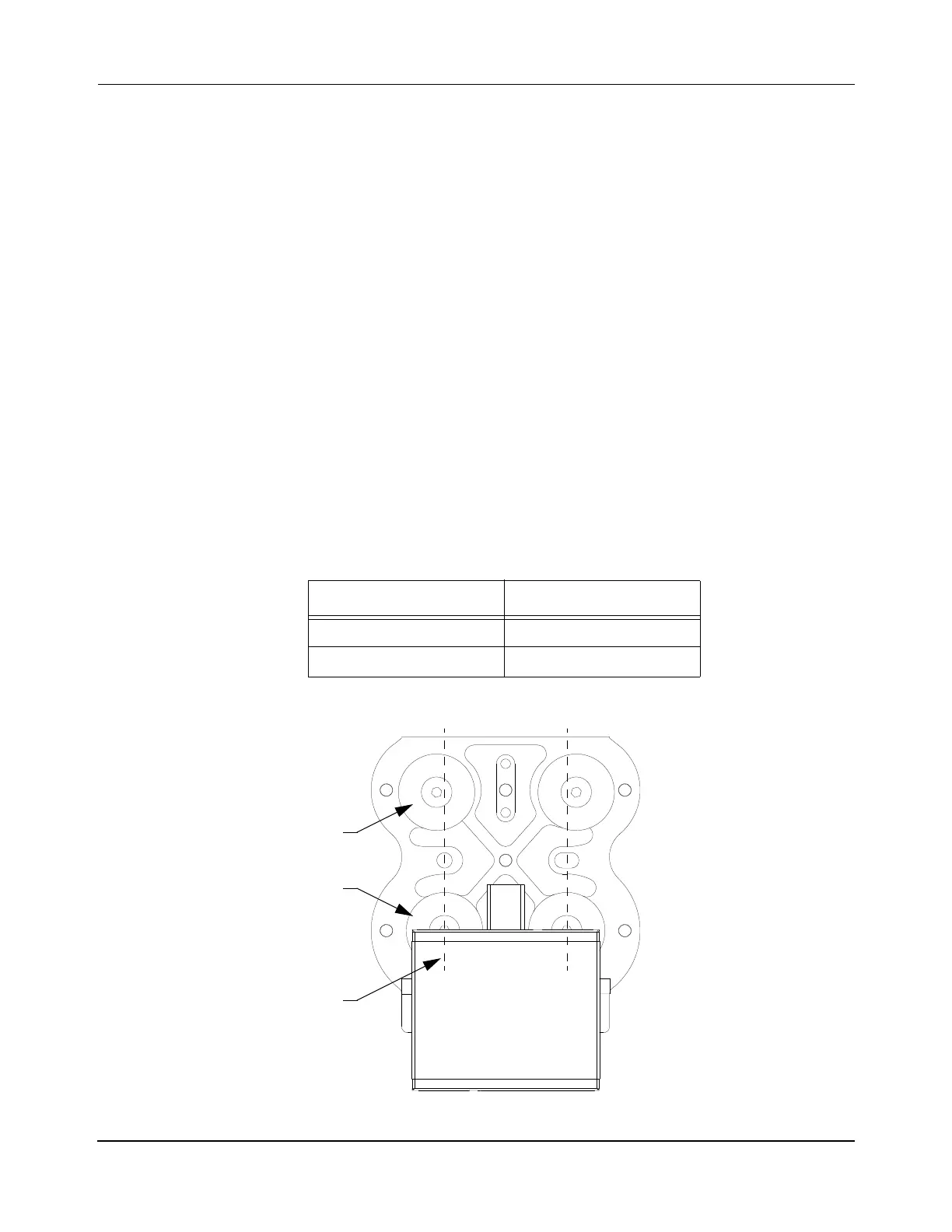

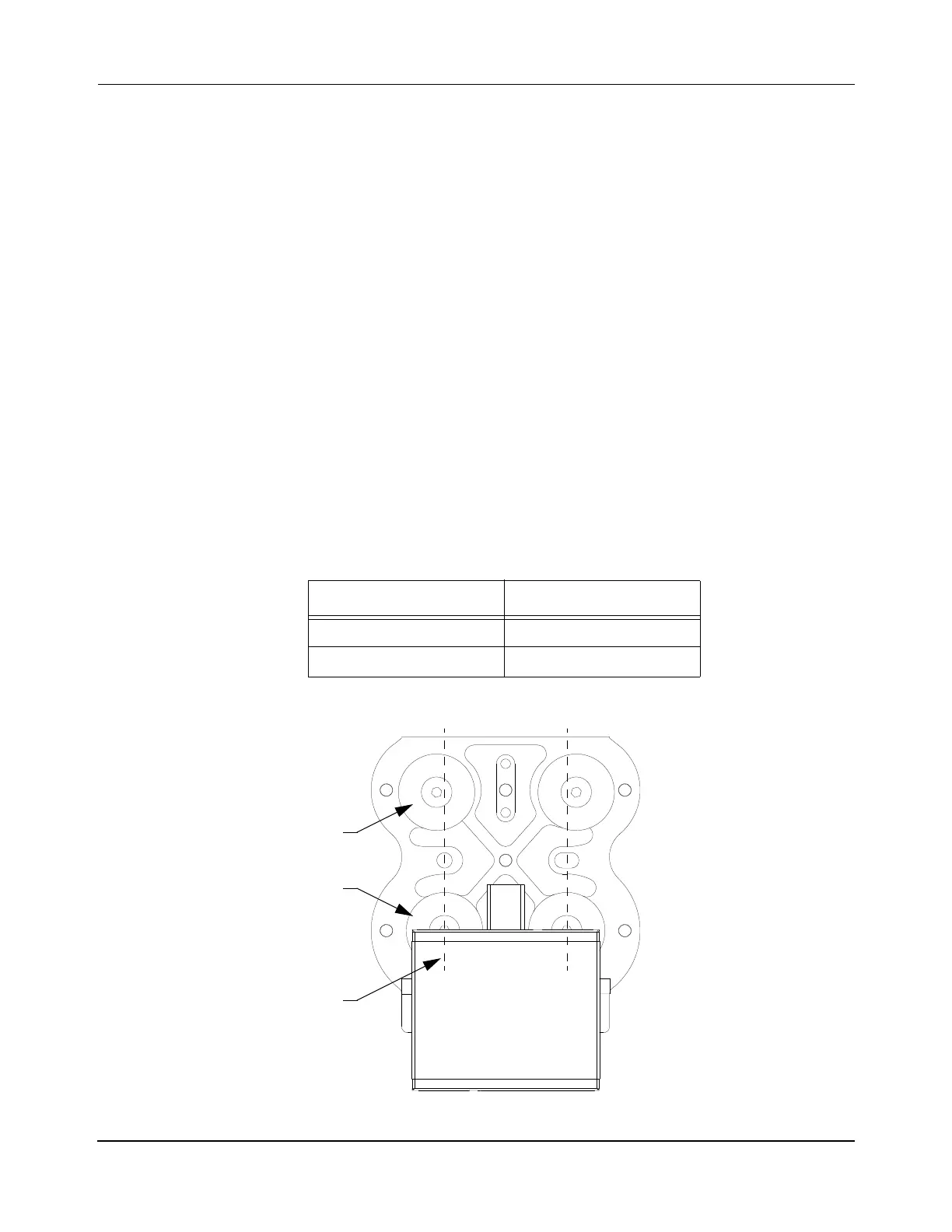

Figure 15: Eccentric Bearing Position

Table 6: Precision Rail Vehicle Drag

Vehicle Type Maximum Drag

Single Array 2.80 N [10.1 ozf]

Dual Array 5.86 N [21.1 ozf]

Concentric Bearings

Eccentric Bearings

Concentric Bearing

Centerline

Loading...

Loading...