23

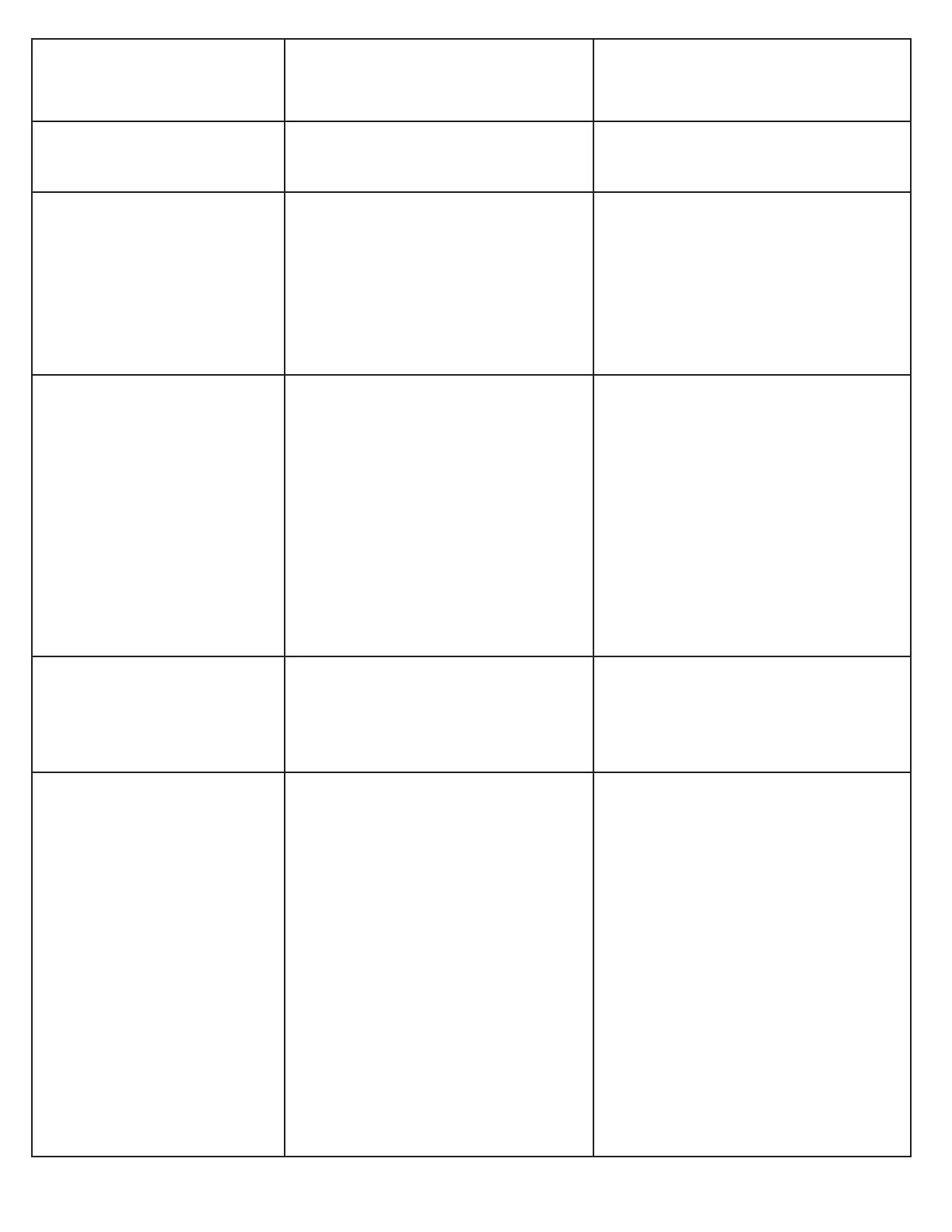

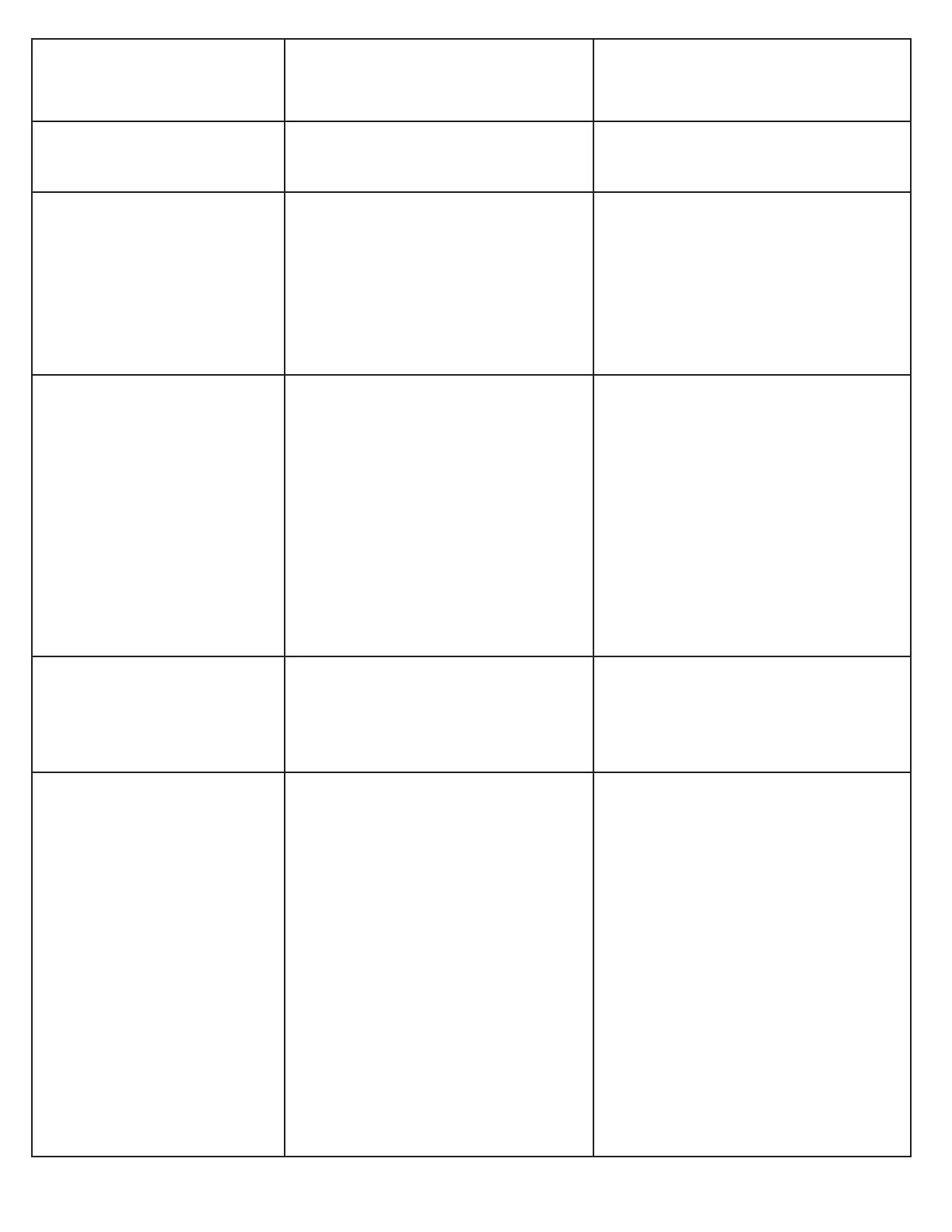

5.2 Troubleshooting by authorized maintenance contractors

Problem Possible cause Actions

Motor does not run. 1. Blown fuse/circuit breaker.

2. Incorrect voltage to motor.

3. Bad wiring connections.

4. Up switch burned out.

5. Motor windings burned out.

1. Replace fuse or reset breaker.

2. Supply correct voltage to motor.

3. Repair and insulate all

connections.

4. Replace switch/control buttons.

5. Replace motor.

Motor runs but will not raise

lift.

1. Overloading lift.

2. Motor running on low voltage.

3. Debris in lowering valve.

4. Pump sucking air.

5. Suction stub off pump.

1. Check vehicle weight and/or

balance vehicle weight on lift.

2. Supply correct voltage to motor.

3. Clean lowering valve.

4. Tighten all suction line ttings.

5. Replace suction stub.

6. Low oil level.

7. Improper relief valve adjustment.

8. Open lowering valve.

6. Fill tank to proper level .

7. Replace relief valve.

8. Repair/replace lowering valve.

Lift slowly settles down. 1. Debris in check valve seat.

2. Debris in lowering valve seat.

3. External oil leaks.

1. Clean check valve.

2. Clean lowering valve.

3. Repair external leaks.

Oil blowing out ller breather

cap.

1. Oil Leak/Pump Failure.

2. Incoming Motor Voltage Incor-

rect.

3. Vehicle Weight And Balance Not

Within Lift Capacity.

1. External oil leak-locate and repair leak.

Internal oil leak-have hydraulic system

serviced by an authorized service repre-

sentative.

2. Supply correct voltage to motor, contact

your local service

authority.

3. Use lift only to rated capacity.

Lift Fails To Raise When

Pushing Raise Button.

1. Raise button defective.

2. Vehicle weight and balance not

within lift capacity

3. Motor rotation incorrect.

4. Incoming motor voltage incorrect

or insufcient

5. Loose or damaged wiring

6. Blown fuse.

1. Replace raise button.

2. Use lift only at rated load.

3. Switch the phase and make sure

motor turns in the direction indi-

cated by the arrow.

4. Supply correct voltage to motor,

contact your local service

authority.

5. Inspect and repair loose or dam-

aged wiring.

6. Check for blown fuse.

The lowering button is

pressed but the lift does not

lower.

1. Obstacles blocking the lowering

phase.

2. Switch is off or power supply is

interrupted.

1. Remove the obstacles blocking

the lowering phase.

2. Check and supply power to lift.

The lift is lowered but one of

the two platforms is higher.

1. Make sure there are no obsta-

cles under the higher platform.

2. Platforms are not level.

3. Air is in one of the slave

cylinders.

1. Remove the obstacle and careful-

ly check the area before operating

the lift.

2. Check to see if lift is installed on

unlevel oor. Level per installation

instructions if needed.

3. Should this problem occur, check

the lift for oil leaks from the cyl-

inders or pipes, if necessary

purge slave cylinder by pressing

the "Override Up" button on the

printed circuit board located in the

cabinet and hold for approximate-

ly 40 seconds.

Loading...

Loading...