40

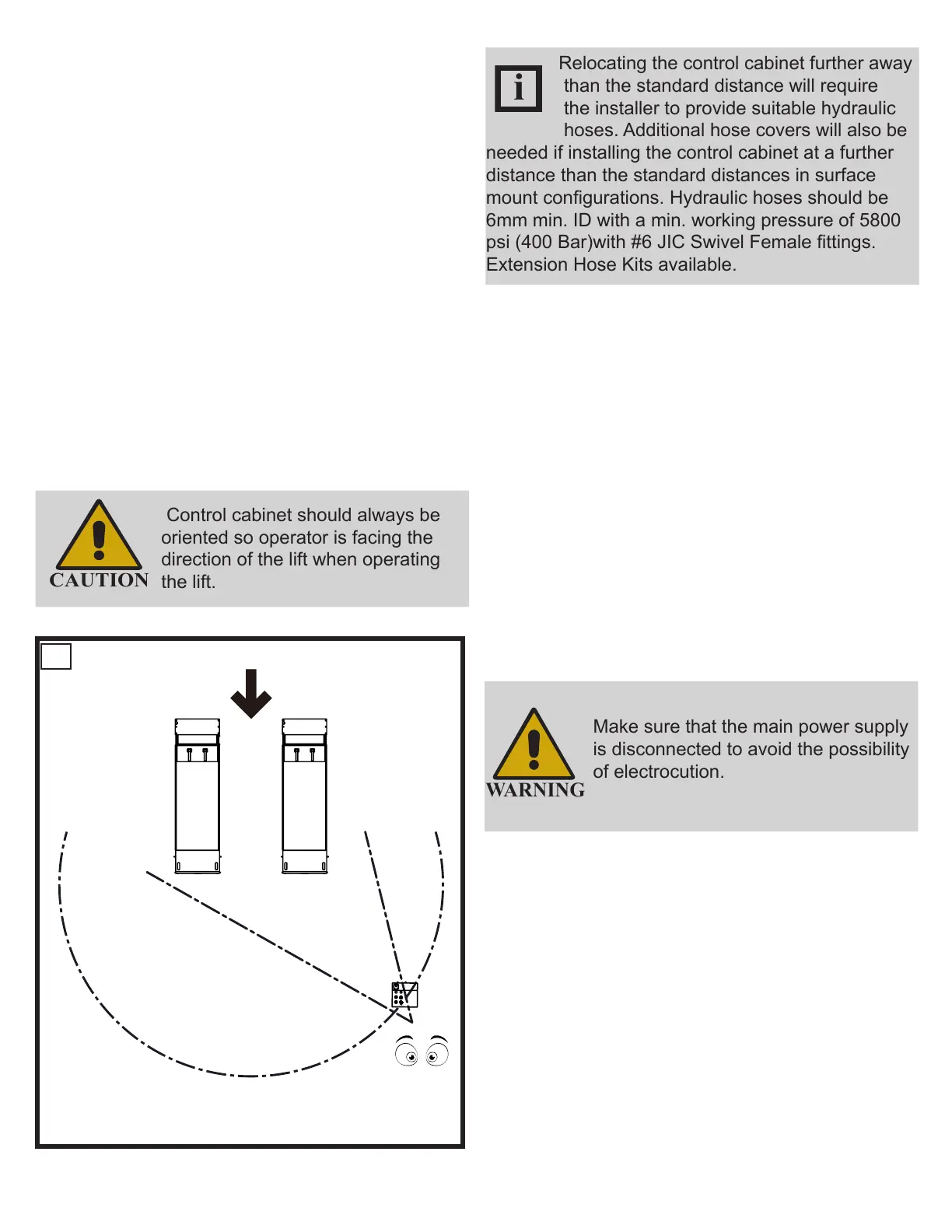

11.4 General lift location

1.Use architects plan when available to locate lift.

see Chapter 7 Technical data.

2.Control cabinet may be placed on the left or right.

3.Place platforms and control cabinet as shown

in Fig. 17 for surface mount or ush mount

applications.

DO NOT anchor any components at this time.

The control cabinet should be located on the

opposite end of vehicle approach, as shown in

Fig. 17. Operator should be in a position to notice

any misalignment of lifting pads or vehicle during

operation. Rotary Lift does not recommend placing

the control cabinet in a different location orientation

and doing so would be the responsibility of the

installer and/or end user.

Recommended Direction of Approach

Control cabinet should always be

oriented so operator is facing the

direction of the lift when operating

the lift.

17

Relocating the control cabinet further away

than the standard distance will require

the installer to provide suitable hydraulic

hoses. Additional hose covers will also be

needed if installing the control cabinet at a further

distance than the standard distances in surface

mount congurations. Hydraulic hoses should be

6mm min. ID with a min. working pressure of 5800

psi (400 Bar)with #6 JIC Swivel Female ttings.

Extension Hose Kits available.

11.5 Control Cabinet Connections

•

Electrical Connection:

Have a certied electrician run appropriate power

supply to motor wire size for a three phase 400V

with 16 amp \ three phase 220V with 25 amp or

single phase 32 amp. circuit.

•

Never operate the motor on line voltage less than

208V. Motor damage may occur.

All wiring must conform to all national and local

electrical codes.

Make sure that the main power supply

is disconnected to avoid the possibility

of electrocution.

•

Connect the limit switch wires to PCB on control

cabinet ,g 18.

•

.Verify the power connection on the control

cabinet connections are complete and correct

base on the wiring schematic(see annex) and

motor connection .g19.

• Connect to power supply line.

DS35EX

Loading...

Loading...