RAPID TOASTER VCT-250

16

P/N 1010776 Rev. H 03/04

McDonald’s

RAPID TOASTER VCT-250

17

P/N 1010776 Rev. H 03/04

McDonald’s

Problem Possible Cause Corrective Action

Conveyor Belt Chain does

not turn or skips sprock-

ets.

Compression Knobs set incor-

rectly.

Set the Bun Thickness Compression Controls to

“D & 5” (for Mfg# 9210600, 602, 604, 618, 620,

& 622). For Mfg# 9210609 to 9210612, set the

controls to “B & 3.” See Figures 2A and 2B.

Interlock Switches not activating. Verify the covers are installed correctly. Repair or

replace damaged conveyor inner cover.

Switches are inoperable. Contact your mainte-

nance person or Authorized Service Agency.

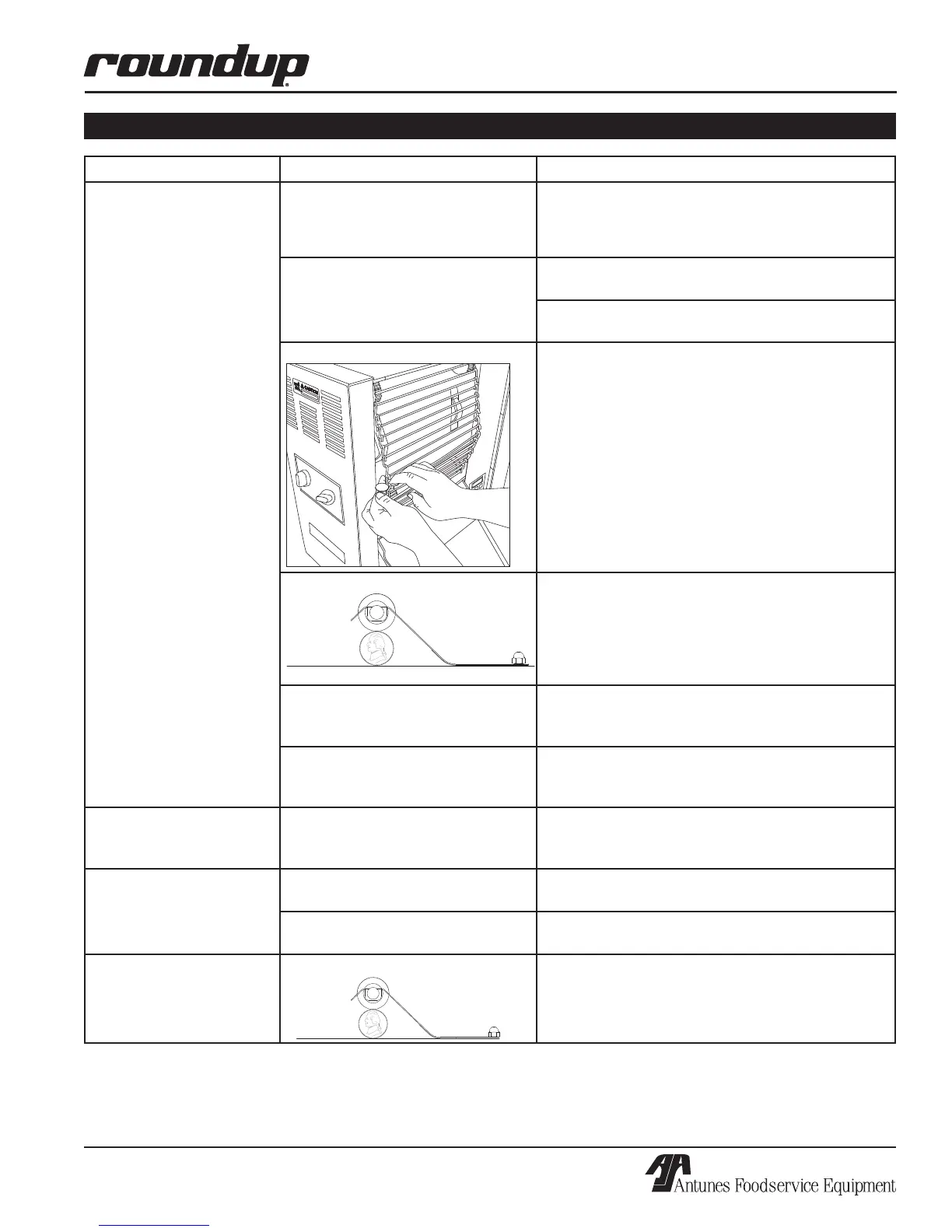

Conveyor Chain is stretched. Open Conveyor covers. Set compression Knobs

to 6 and F. Facing the Heel/Club side, locate the

approximate center point of the groovy Belt. Pull

the conveyor Chain away from the edge of the

toaster. Stand a U.S. Quarter (15/16” or 2.5 cm)

between the frame and the chain. If the gap is

significantly greater, REMOVE links (refer to the

instructions in the Maintenance section of this

manual). If you cannot stand a coin in the gap,

you may have to ADD a link. Duplicate this pro-

cedure for the CROWN side using a U.S. Dime

coin (11/16” or 1.8 cm).

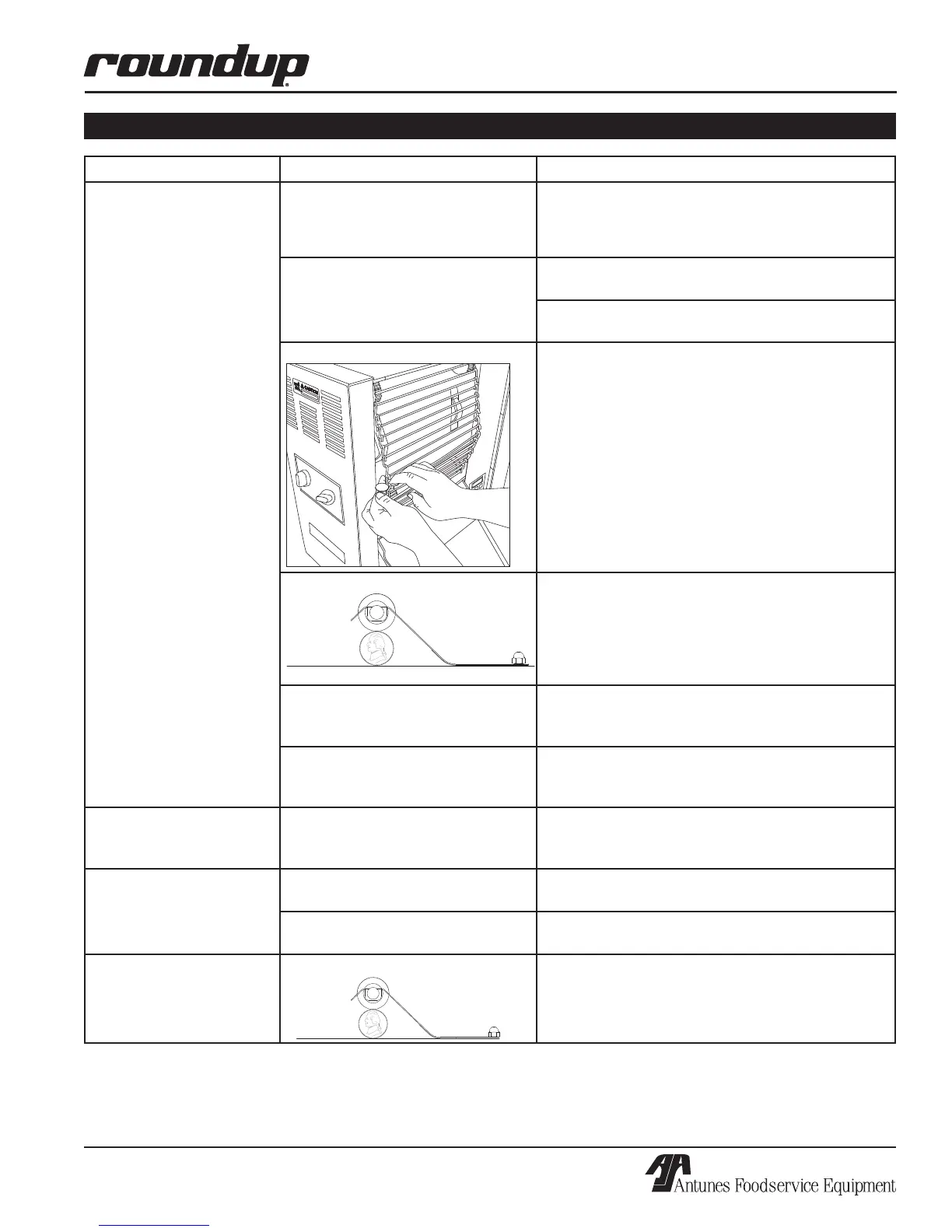

Roller Tensioner bent or missing.

Adjust the bent Roller Tensioner - measured to

13/16” (2.1 cm) or the height of a U.S. Nickel coin

from the bottom of the roller to the inner cover.

Note: Damaged Roller Tensioners should be

replaced.

Motor Drive Chain is off or dry. Have a qualified maintenance person or your

Authorized Service Agency reinstall and/or lubri-

cate the chain.

Motor does not operate. Have a qualified maintenance person or your

Authorized Service Agency inspect all electrical

connections and, if necessary, replace the motor.

Groovy Belt wrap stop

turning, but conveyor

chain continues to turn.

Underside of Groovy Belt and

Conveyor Chain have excessive

caramelizing buildup.

Clean Belt Wrap and Conveyor Belt Chain as per

current MRC Card (TS 019).

Flap covering connecting

hinge or wavy rib on Belt

Wrap is getting torn or

worn.

The inner Conveyor Cover has

been damaged (bent in at the top).

Repair or replace the inner conveyor cover.

Groovy Belt Wrap has been

installed upsidedown.

Reinstall Groovy Belt Wrap with flap down.

Groovy Belt Wraps are

tearing in the center.

Missing or Bent Roller Tensioners. Replace or adjust the bent Roller Tensioner -

measured to 13/16” (2.1 cm) or the height of a

U.S. Nickel coin from the bottom of the roller to

the inner cover.

TROUBLESHOOTING (continued)

Loading...

Loading...