33 / 72

Horizontal End Suction Pump for Chemical Process, ASME B73.1-2001

Installation, Operation, and Maintenance Manual – CPP21

SECTION SIX - LUBRICATION

6.1 OIL LUBRICATION

6.1.1 Recommended Lubricant

The recommended bearing frame oil is ISO VG 68 non-detergent oil. Turbine quality oil is preferred. This oil may

be used during break-in and normal operation.

6.1.2. Method of Application

Customer must fill bearing frame before startup. The bearing frame is supplied with a sight glass. Fill the bearing

frame with oil according until the middle of the oil sight.

Pour oil into the bearing frame through the breather connection located at the top of the bearing frame, leaving

an amount equal to the capacity of constant level oiler bottle apart. The correct level is observed in the middle

of the oil sight glass.

• Oil level should be determined by using sight glass in bearing frame. Oil level in

optional constant level oiler does not correspond to oil level in bearing frame.

• Ruhrpumpen takes every precaution during our assembly process and

subsequent final assembly audits to ensure no Bearing Frame oil leaks exist

prior to shipment. Oil can leak past the labyrinth seal in an “overfill” condition.

Refer to the filling instructions for additional information

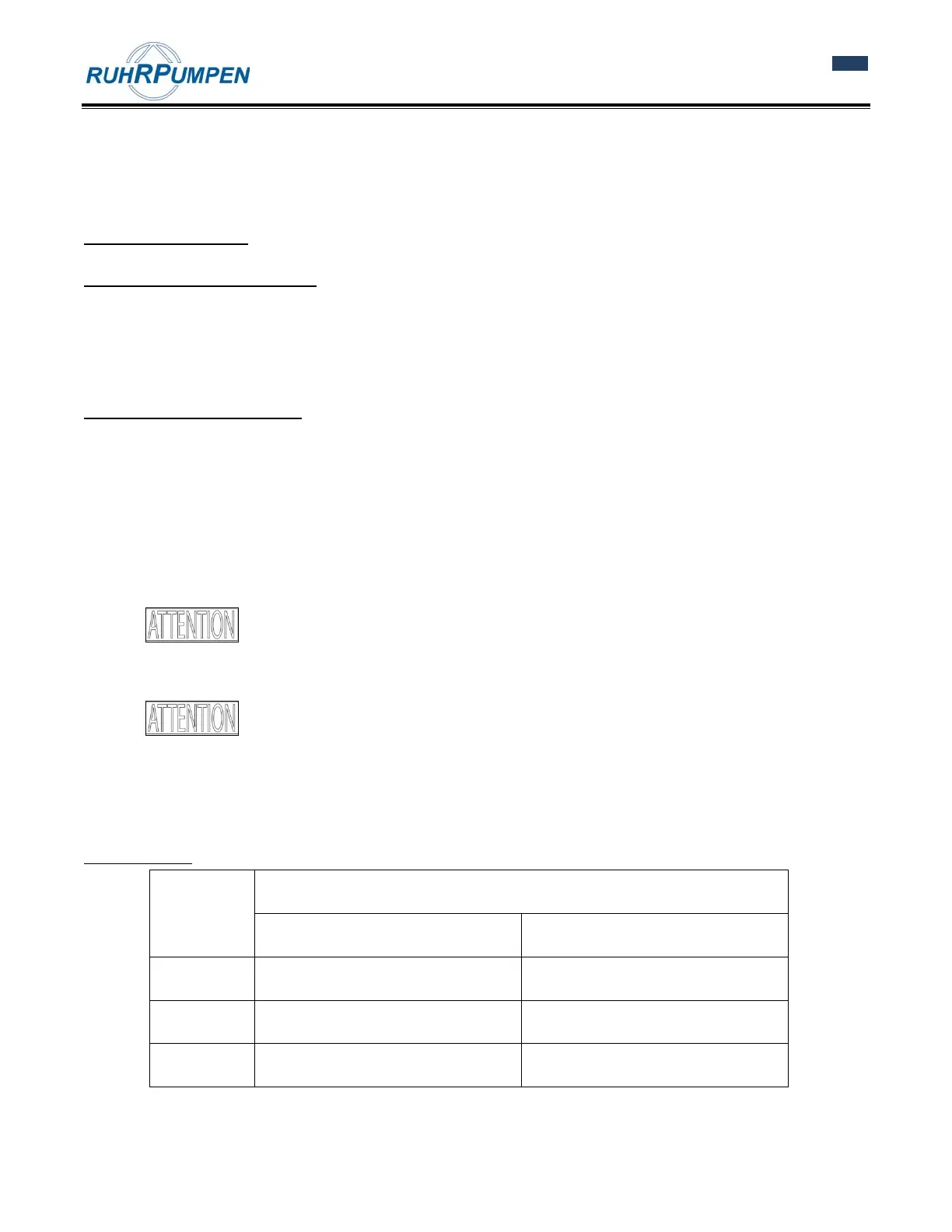

6.1.3 Quantity

Frame

Oil quantity

U.S. gallons L

10 0.13 0.50

30A 0.20 0.75

30B 0.40 1.50

Loading...

Loading...