6 / 72

Horizontal End Suction Pump for Chemical Process, ASME B73.1-2001

Installation, Operation, and Maintenance Manual – CPP21

1.2 PUMP CASE, IMPELLER, AND WEAR RINGS

1.2.1 Pump Case

The pump case is foot mounted.

1.2.2 Impeller and Wear Rings

The impeller is dynamically balanced. The balancing is either single or two-plane, to meet the requirements of

ISO 1940 Grade 6.3. The impeller is threaded to the shaft.

1.3 CASE COVER

The case cover is designed to accept a wide variety of single or double mechanical seals and to comply with

ASME B73.1-2001 dimensional requirements.

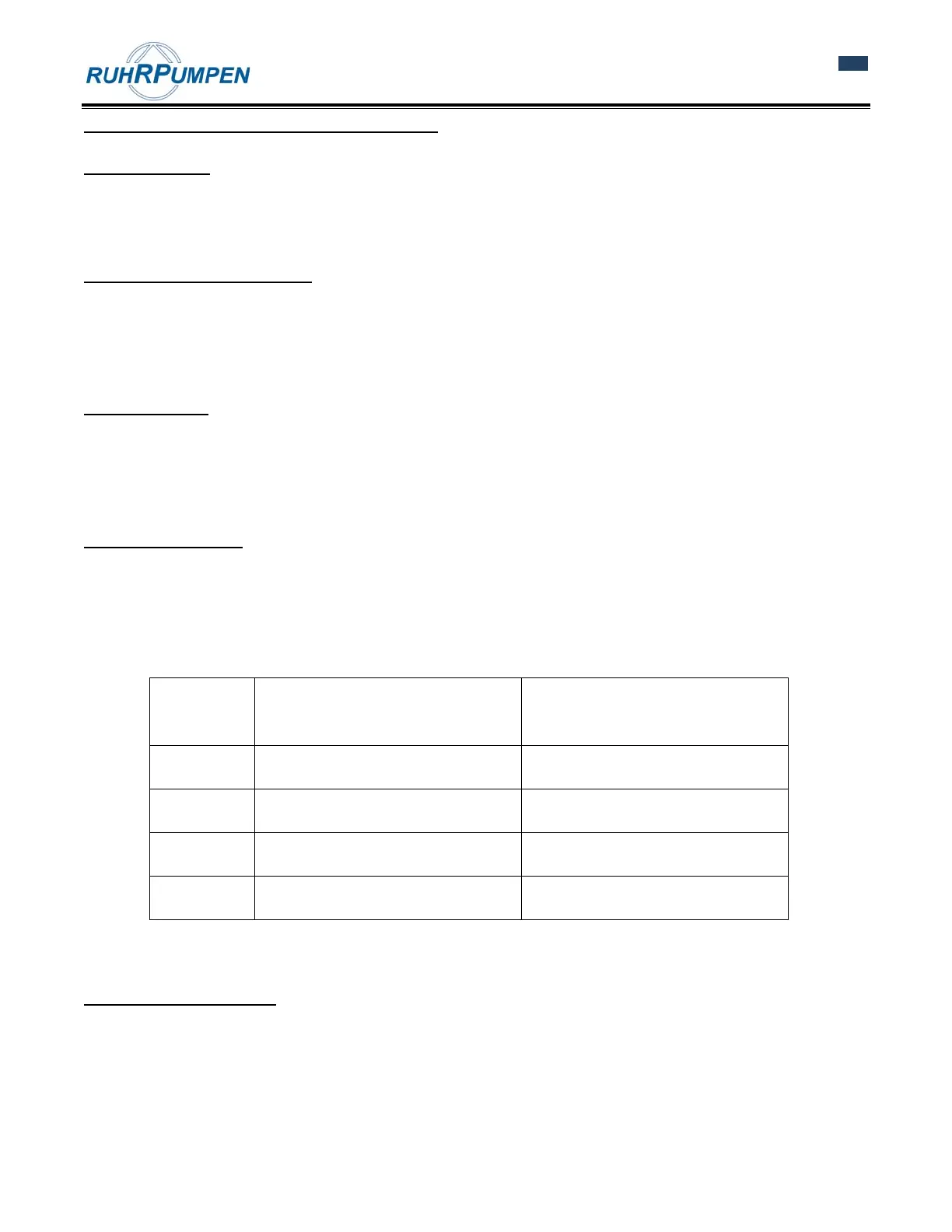

1.4 BEARING FRAME

The bearing frame, which also serves as a large reservoir for oil lubrication, encloses the two ball type angular

contact thrust and deep groove ball radial bearings. The bearing frame, closed at each end by a cover and lip

seal or labyrinth seal, is cast with fins for air cooling but optional water cooling is available.

Frame

Radial (Deep groove ball bearing,

single row)

Thrust (Angular contact ball

bearing, double row)

10 6208 5307 E

30A 6310 5310 E

30B 6311 5310 E

50 6314 5314 E

When purge or pure oil mist is specified, appropriate connections will be identified on the bearing frame. See

SECTION SIX - LUBRICATION for more details.

When water cooling is specified, a cooling coil is used.

Loading...

Loading...