43 / 72

Horizontal End Suction Pump for Chemical Process, ASME B73.1-2001

Installation, Operation, and Maintenance Manual – CPP21

8.3 REASSEMBLY

• Observe the plant's safety precautions when lifting heavy components. Request

help when moving or positioning them.

• Mounting of bearings should be carried out in a dry, dust free area away from

metal working or other machines producing shavings and dust to avoid

contamination of bearings.

• The bearings should remain in their original packaging. Once they are to be

assembled in the shaft, they must be removed from their packaging, and the

preservative in the outside diameter and the bore must be wiped out.

• Bearings should be demagnetized before mounting them, to avoid

contamination.

Reassemble as follows:

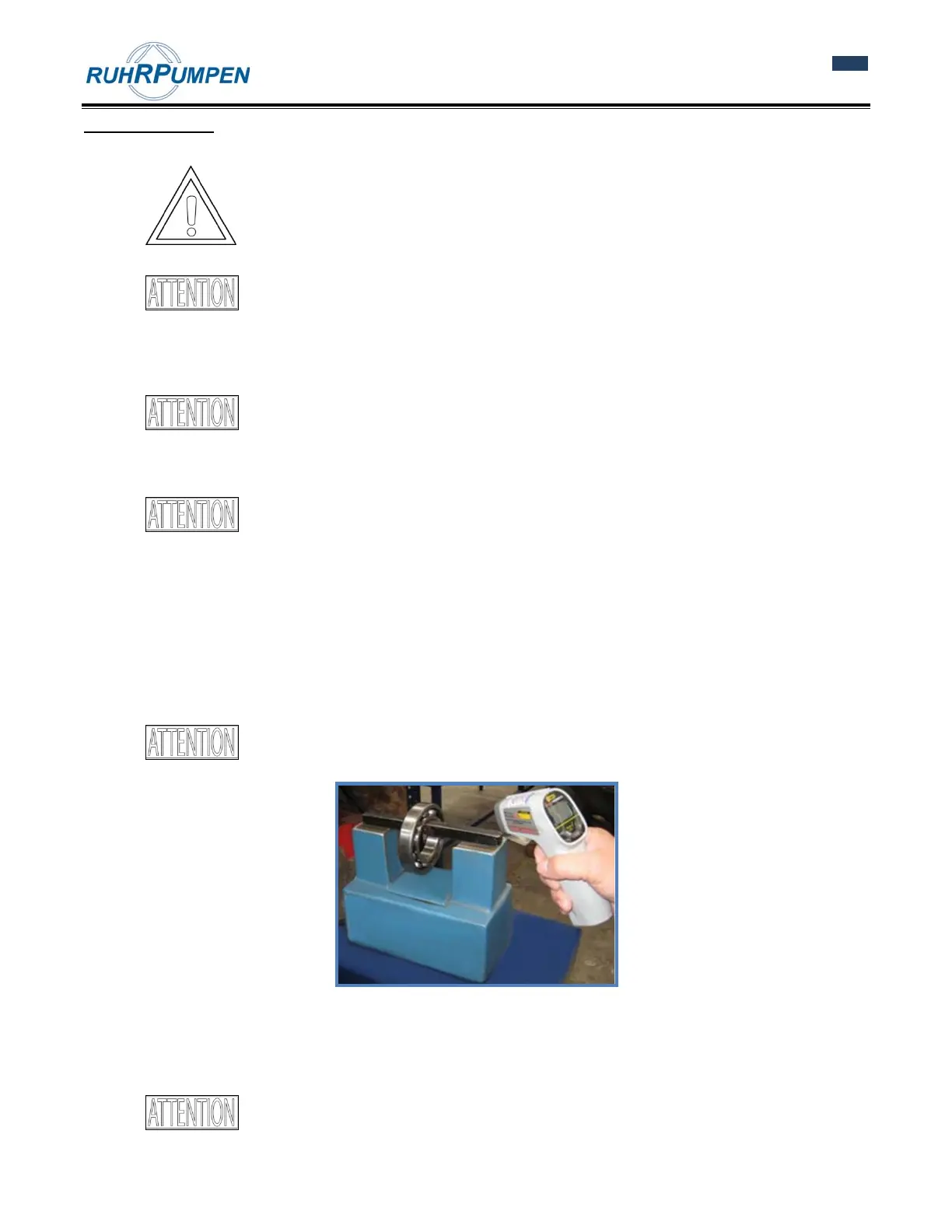

1. Place and heat the thrust bearing in an induction heater. Turn on the heater. Continuously measure the

temperature of the inner race, looking to reach 230 °F (110 °C).

• Measure the temperature continuously with an infrared thermometer, pointing

to the inner race of the bearings.

Figure 8.1 Heating the thrust bearing.

2. Position the shaft vertically (with the coupling side upward) in a press.

• Cover the jaws of the press with soft material to prevent damaging the shaft.

Loading...

Loading...