69 / 72

Horizontal End Suction Pump for Chemical Process, ASME B73.1-2001

Installation, Operation, and Maintenance Manual – CPP21

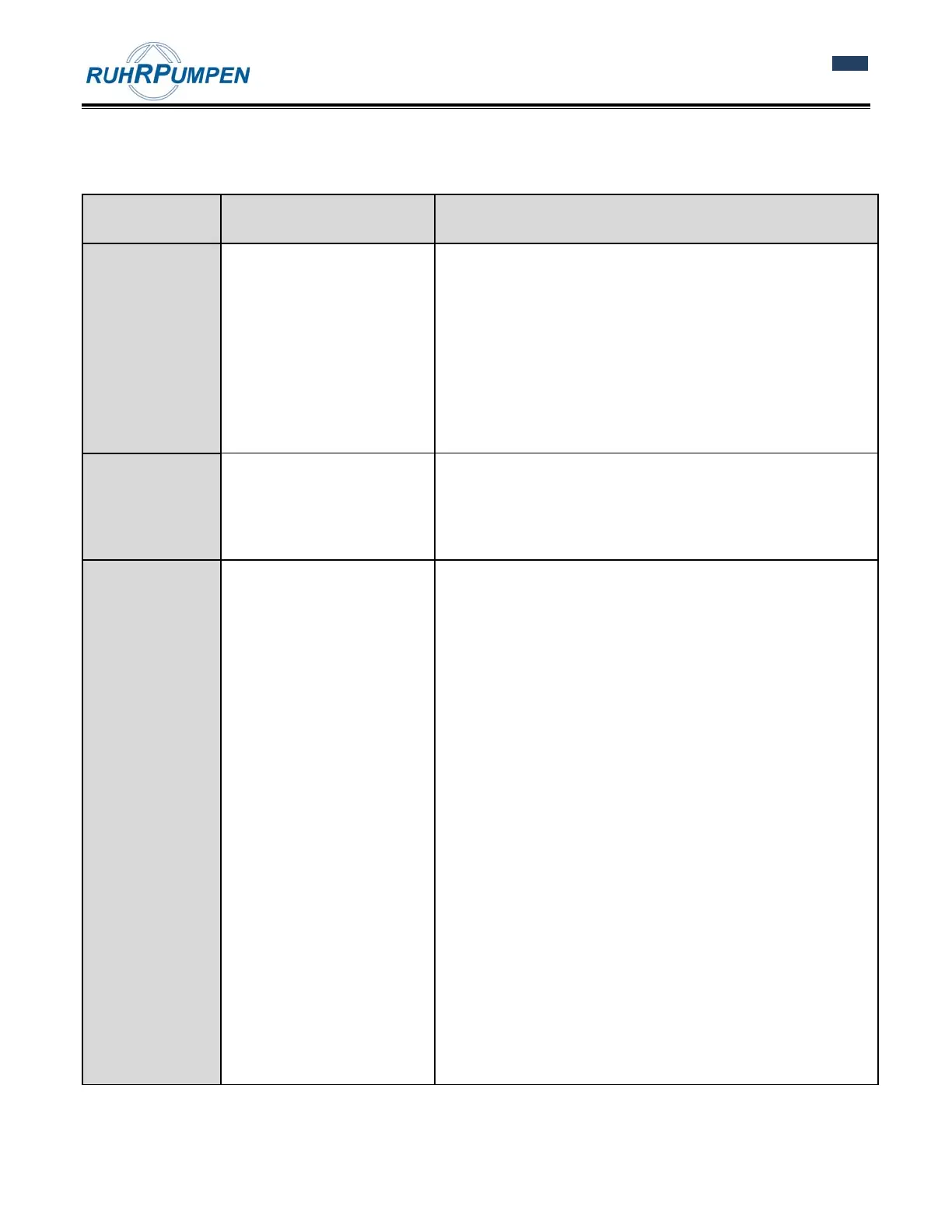

SECTION ELEVEN - TROUBLESHOOTING CHART

TROUBLE PROBABLE CAUSES SUGGESTED SOLUTION

HOT BEARINGS

a. Insufficient Oil

b. Contaminated Oil

c. Misalignment

d. Too much oil

e. Pump is under tension

stress

f. Excessive axial thrust

g. The given half-coupling

spacing is not set

h. Bearings are damaged

a. Add Oil.

b. Drain and clean reservoir. Refill with clean oil.

c. Check alignment of pump and driver.

d. Drain to proper level.

e. Check the piping for tension free connections

f. Clean balance holes in the impeller and change the seal

rings.

g. Reset and give the correct spacing.

h. Change damaged bearings.

LEAKAGE

UNDER SHAFT

SLEEVE

b. Pump unit is not properly

aligned

c. The given half-coupling

spacing is not set

b. Realign the pump

c. Reset and give the correct spacing.

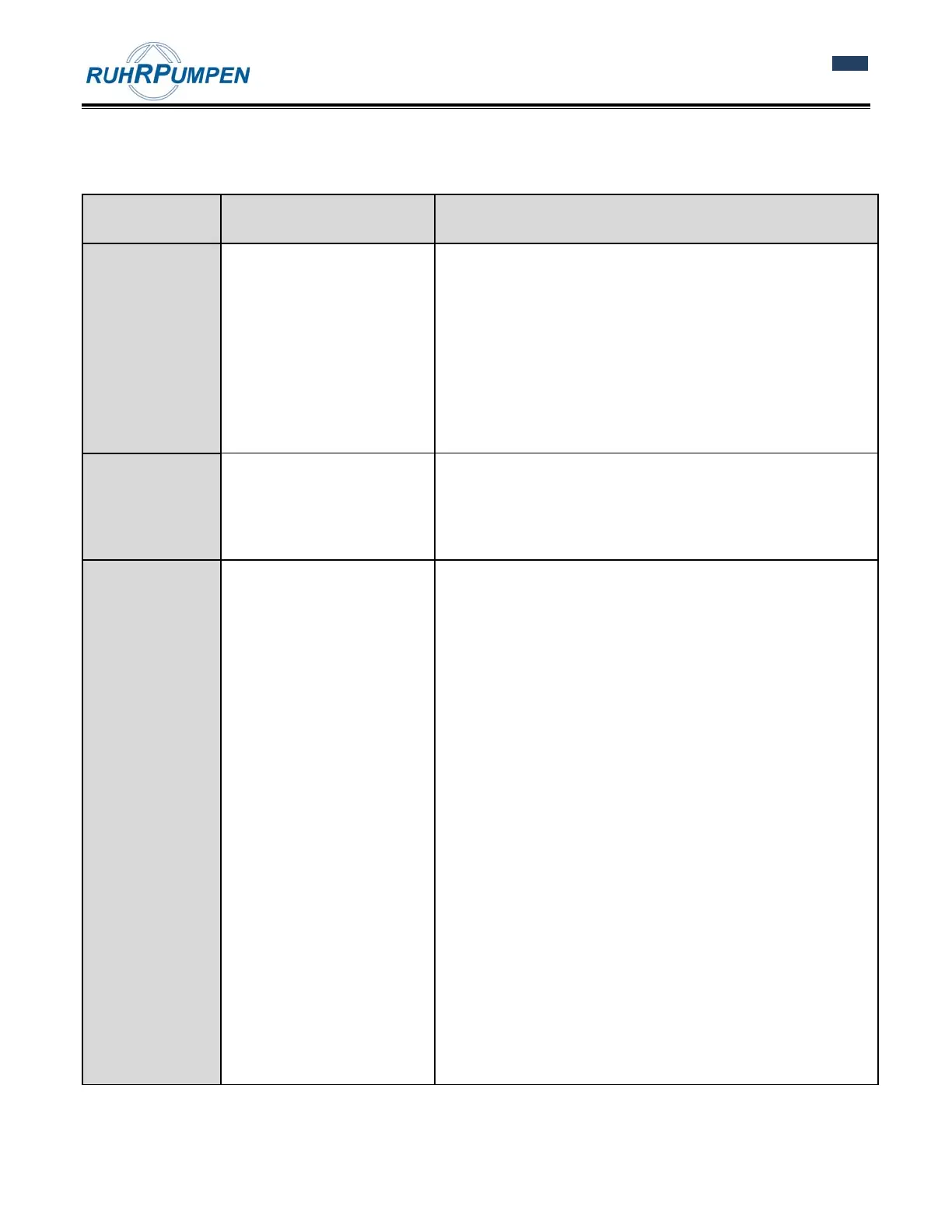

PUMP DOES

NOT DELIVER

LIQUID

a. Inner pump parts are

worn

b. Density or viscosity of

pumped fluid is not same as

designed.

c. The motor voltage is

incorrect

d. Motor runs only in two

phase mode

e. Pump not primed

f. Speed too low

g. Feed pipe or impeller

plugged

h. Clogged suction

i. Damaged impeller

j. Wrong rotation

k. Pump or piping are not

properly vented

l. Formation of air pockets

in the piping

m. The counter pressure of

the system is greater than

the design point of the

pump

n. NPSHa too low

a. Change worn parts

b. Consult a Ruhrpumpen dealer.

c. Apply correct voltage to the motor

d. Check the cables, connections and fuses

e. Prime pump.

f. Check driver input.

g. Clean pipe and impeller.

h. Clean out suction line.

i. Replace impeller.

j. Check driver rotation.

k. Vent or top up.

l. Install vent valve or lay piping elsewhere.

m. Open discharge valve as wide as necessary to reach the

operating point.

n. Check the fluid level in the feed container.

Open suction valve completely.

Lay suction pipe elsewhere is friction losses are too big.

Check for a possible filter in the feed pipe.

Loading...

Loading...