48 / 72

Horizontal End Suction Pump for Chemical Process, ASME B73.1-2001

Installation, Operation, and Maintenance Manual – CPP21

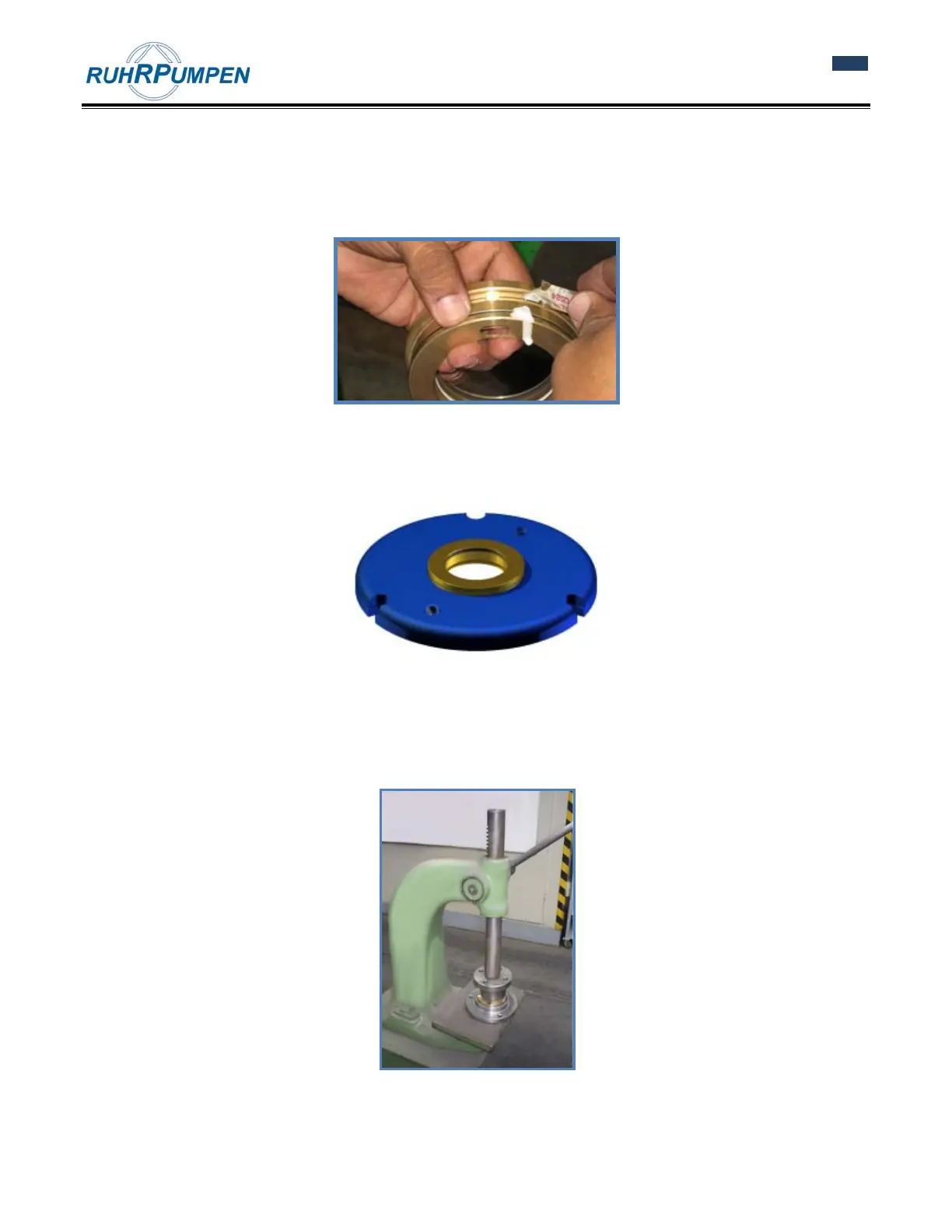

11. To insert the labyrinth seals into the covers, follow these steps:

a. Lubricate the outside ring of the labyrinth seal. Lubricant supplied by isolator manufacturer or P-

80 Rubber Lubricant Emulsion is recommended (grease is NOT recommended).

Figure 8.10 Lubricating the labyrinth seal.

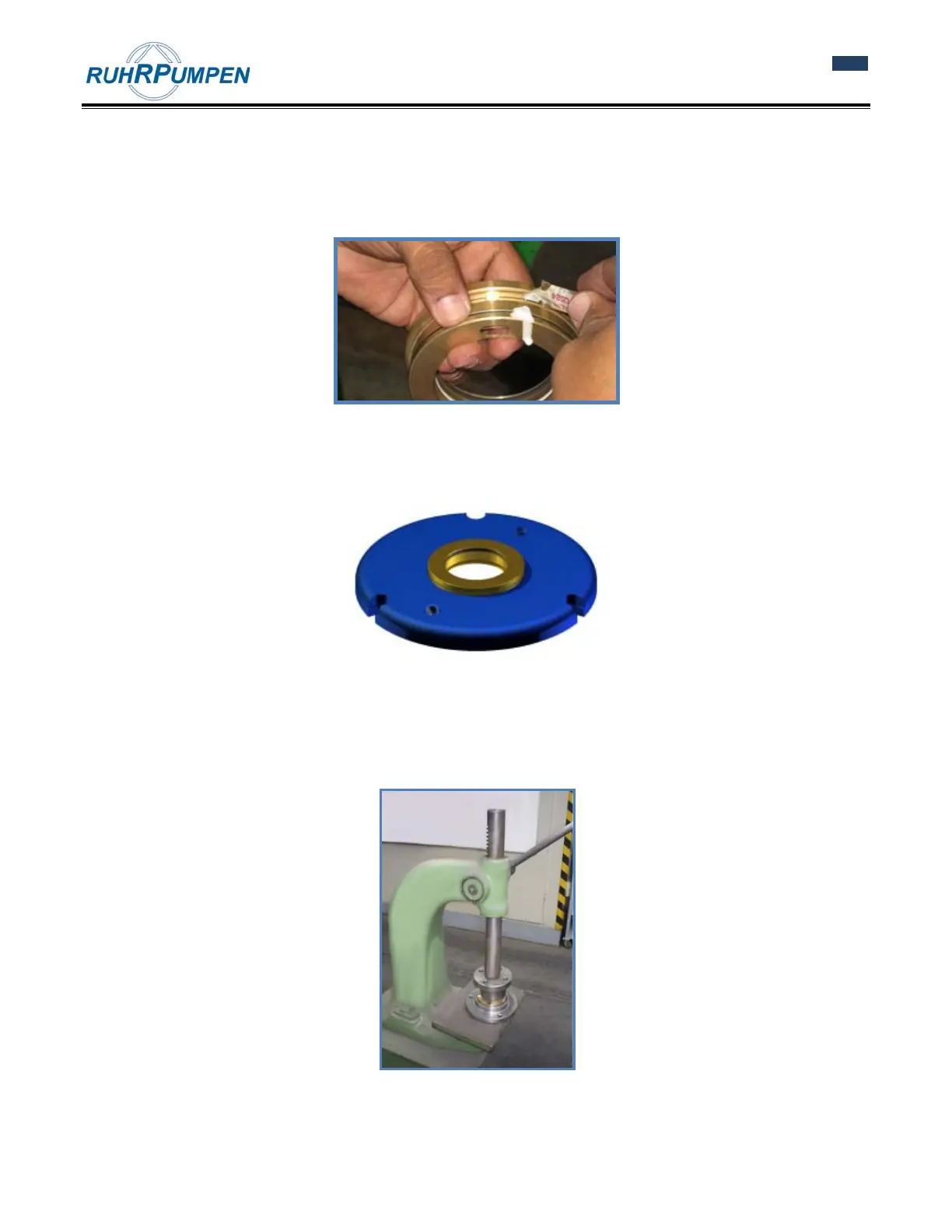

b. Position the labyrinth seal at the bearing cover in its correct position (with the internal drain slot

of the labyrinth seal at the 6 o’clock position of the bearing cover).

Figure 8.11. Labyrinth seal and bearing cover.

c. Ensure the labyrinth seal is perpendicular to bore before insertion.

d. Using a sleeve and a flat surface (hard plastic) with the help of an arbor press, insert the

labyrinth seal.

Figure 8.12 Inserting the labyrinth seal.

Loading...

Loading...