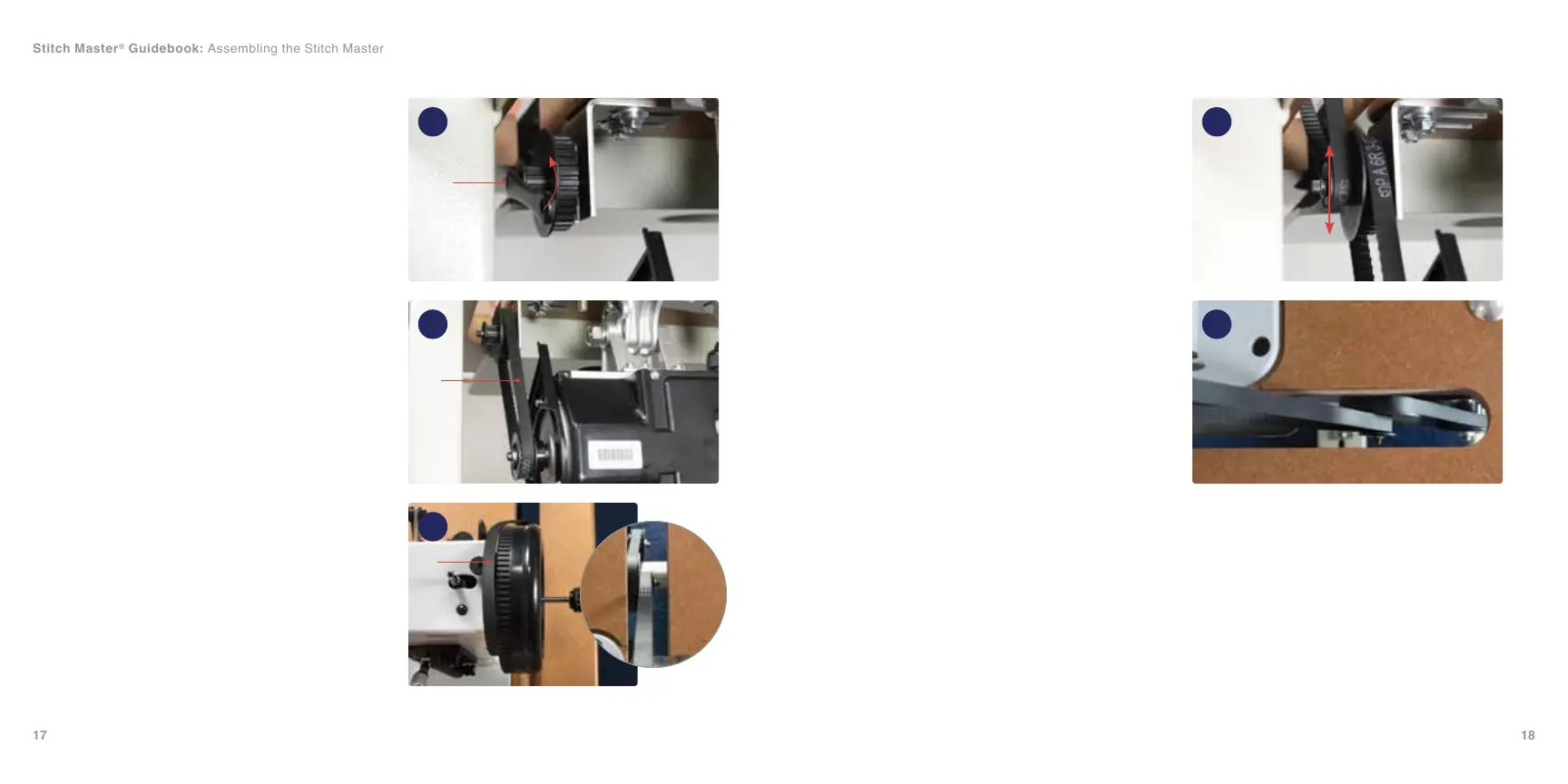

Installing Timing Belts

1. Find the long and short timing belts (A &

B) and box end wrench in the accessory

box. Use the box end wrench to loosen

the shaft of the idler pulley (C) so that

the pulley shaft will be able to move up

and down (29). Take the shorter timing

belt (B) and place it over the big pulley

of idler pulley (30) and around the motor

pulley. Then push the shaft and pulley up,

tensioning the belt and tighten with the box

end wrench.

2. Place the larger timing belt (A) over, and to

the left of, the Power Plus™ Flywheel (D).

Feed the belt through the belt slot and onto

the small pulley of the idler pulley (31).

Turn the Flywheel while guiding the belt

into place around the Power Plus wheel

from the inside (just like a bicycle chain).

Rotate the Power Plus Flywheel to make

sure that both belts are aligned correctly.

The position of the Idler Pulley L-bracket

and the Workhorse™ Servo Motor can be

adjusted for perfect alignment.

3. Check the tension of both timing belts by

pressing at the middle of each belt. There

should be equal tension between the two

belts. If one is more loose, use the box

end wrench to loosen and tighten the idler

pulley accordingly (32).

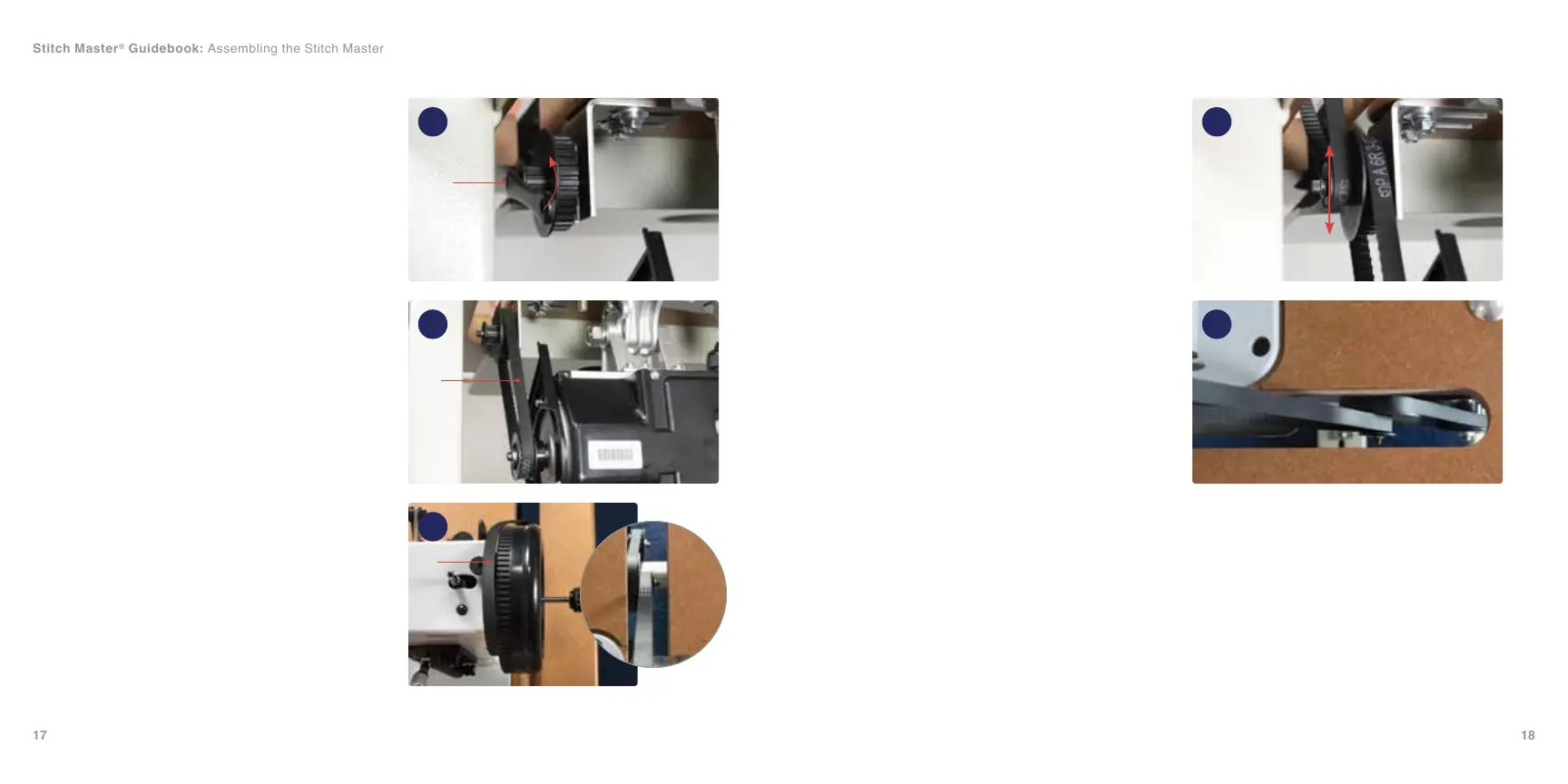

4. To check the belts at speed plug in the

Workhorse Servo Motor and turn on the

motor by toggling the power switch. Press

the treadle to make sure the Power Plus

Flywheel is rotating from the top toward

you. Both timing belts (A and B) should

track without side-to-side movement and

be well clear of the belt slot edges (33).

The needle will not move since the Posi-

Pin

®

is not yet in the engaged position.

If you nd you need to change the motor

rotation, the steps below will assist you.

30

32

31

33

29

C

B

A

D

A

B

Stitch Master

®

Guidebook: Assembling the Stitch Master

Loading...

Loading...