6105

6105

6105

6105 Belt

Belt

Belt

Belt Feeder

Feeder

Feeder

Feeder integrator

integrator

integrator

integrator ---

---

---

--- User

User

User

User ’

’

’

’ s

s

s

s Guide

Guide

Guide

Guide ---

---

---

---

63

deviation is found, the reading can be corrected by adjusting the potentiometer. However, in case that a

remarkable deviation exists, the current output board is bad and needs to be changed.

When the 6105 gives correct current output at zero flowrate, the current output at various known

flowrates should be checked. Apply reference weights on the scale and press RUN key on the 6105

integrator to determine the flowrate at a percentage of the full load. For example, a belt scale with scale

capacity of 100t/h displays “ 10 ” , then the reference weight is 10% of the scale capacity. In this case the

milli-amperometer shall give a reading with the same percentage of the full scale. For this example, the

reading of the milli-amperometer shall be 16 (20-4)X10%+4mA = 5mA. If incorrect reading occurs, the

current output board should be repaired or changed.

No

Yes

No

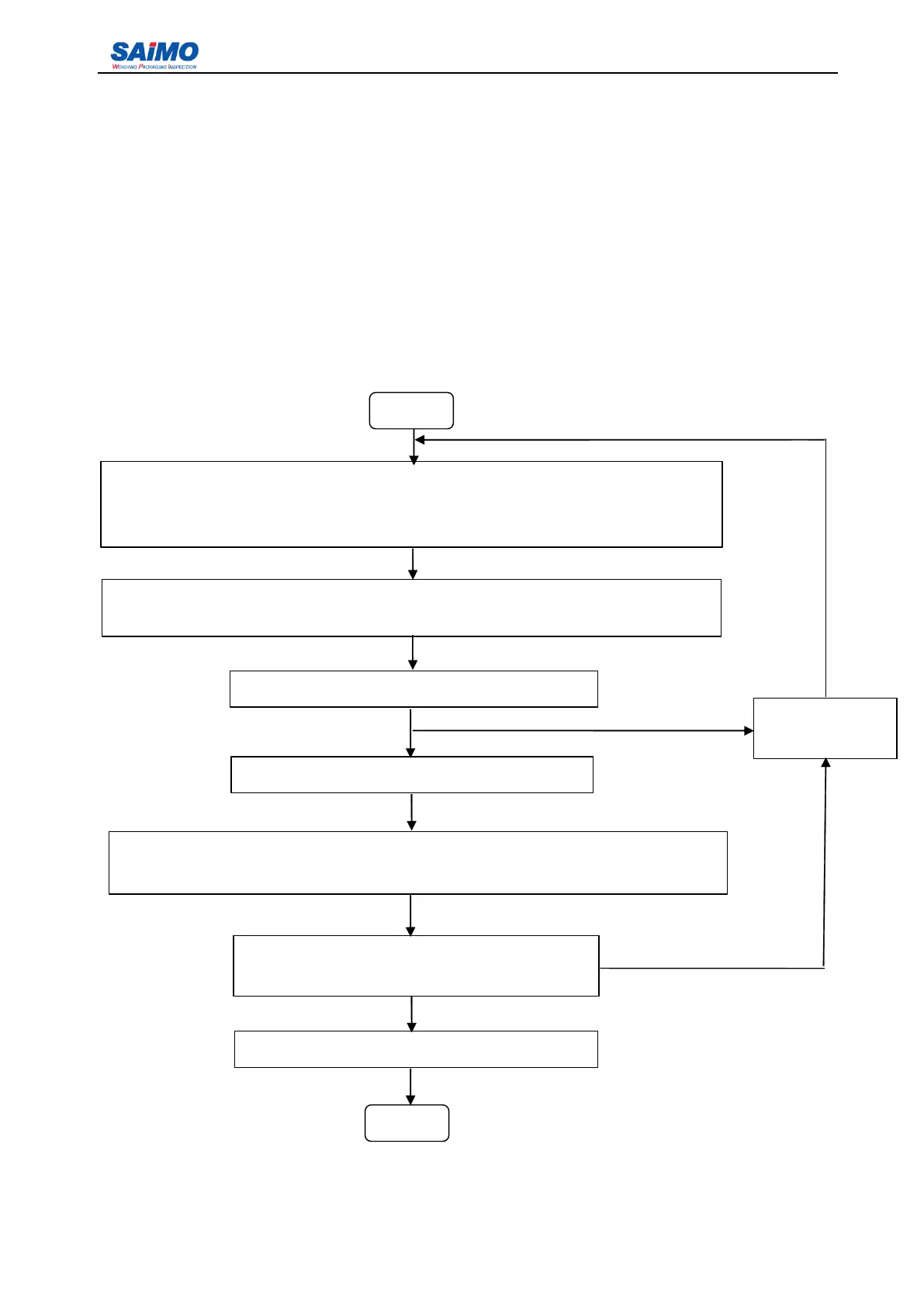

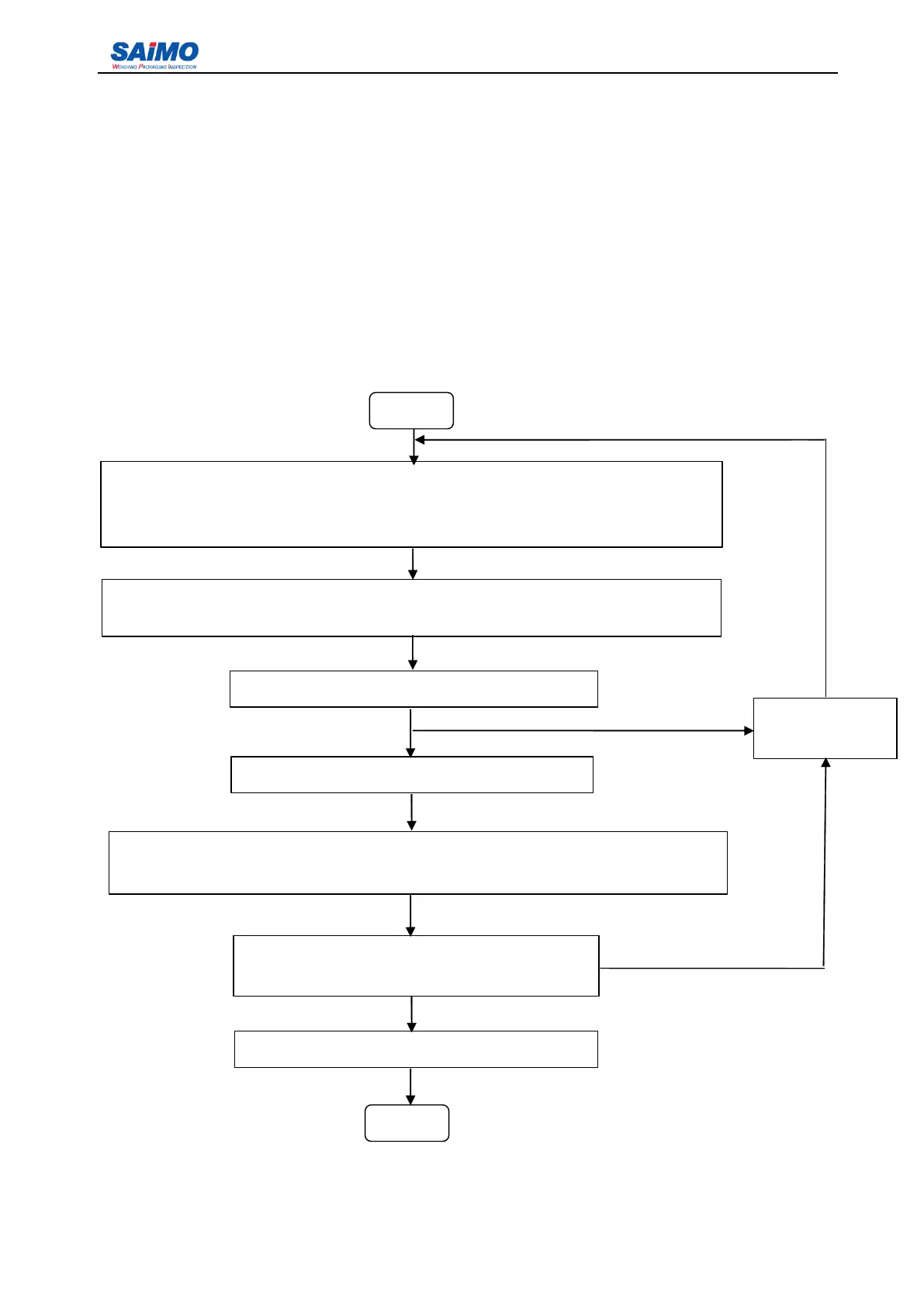

Figure 6-4 Troubleshooting Current Output

Start

Check the current output. Connect power supply to the system. Run the belt empty

at the normal speed, the flowrate indication should be zero. Remove the

connections on the signal output terminals which are then connected to a

milli-amperometer.

Check the flowrate indication at current output of 4mA, which should be zero.

Otherwise, perform zero calibration.

The reading of milli-amperometer should be 4mA

The current output is normal – 4mA

Check the current output at a known flowrate. Apply reference weights on the scale

and press RUN key to determine the flowrate at a percentage of the scale capacity.

Check the milli-amperometer gives a reading

with the same percentage

The current output baord functions well

End

Bad current

output board

Loading...

Loading...